|

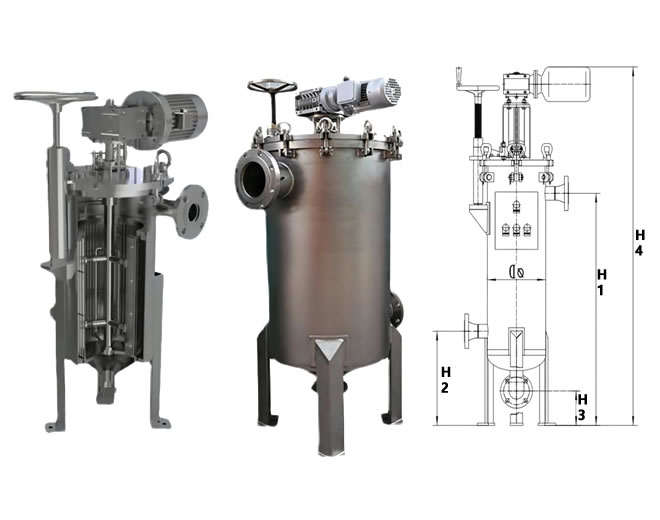

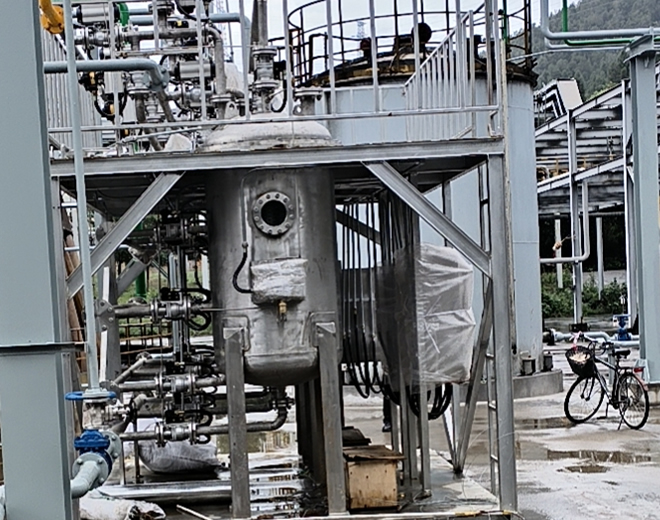

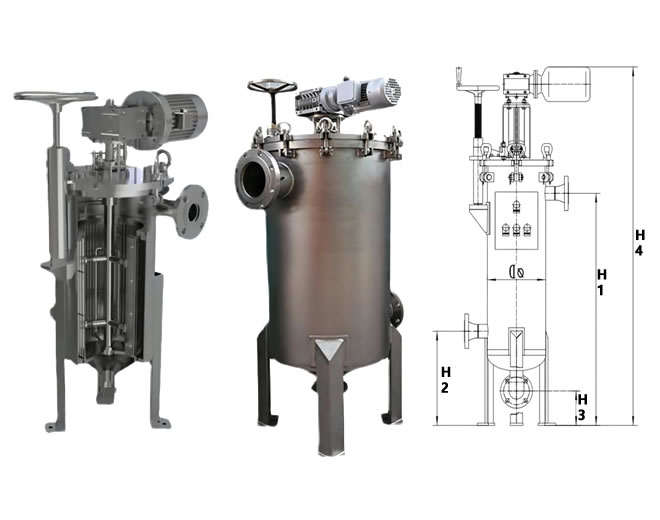

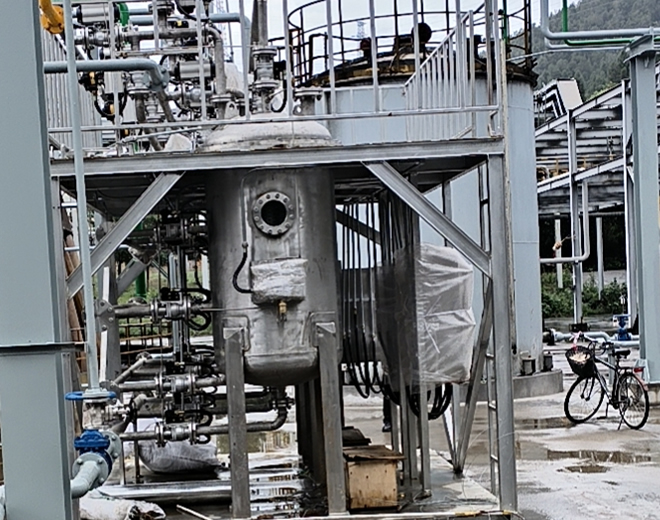

I. Overview Impurities in liquids during the production process can significantly affect the lifespan of catalysts or related equipment, leading to serious clogging. Precision filters are essential for fine chemical liquid filtration, as well as in organic chemistry, pharmaceuticals, edible oils, wastewater treatment, and other industries. These filters are characterized by high flow rates, continuous operation, high filtration precision, and easy clogging of filter elements. The HMS automatic backwashing filtration system effectively addresses these challenges by integrating automation technology, gas storage backwashing technology, and advanced new welding filter materials. |

|