Description

Fuel filtration is a critical process to ensure the stable operation of engines, fuel systems, and industrial combustion equipment. Stainless steel filter elements, with their excellent performance, play an important role in fuel filtration. Below are their key functions and advantages:

I.Efficient Filtration of Impurities, Protecting the Fuel System

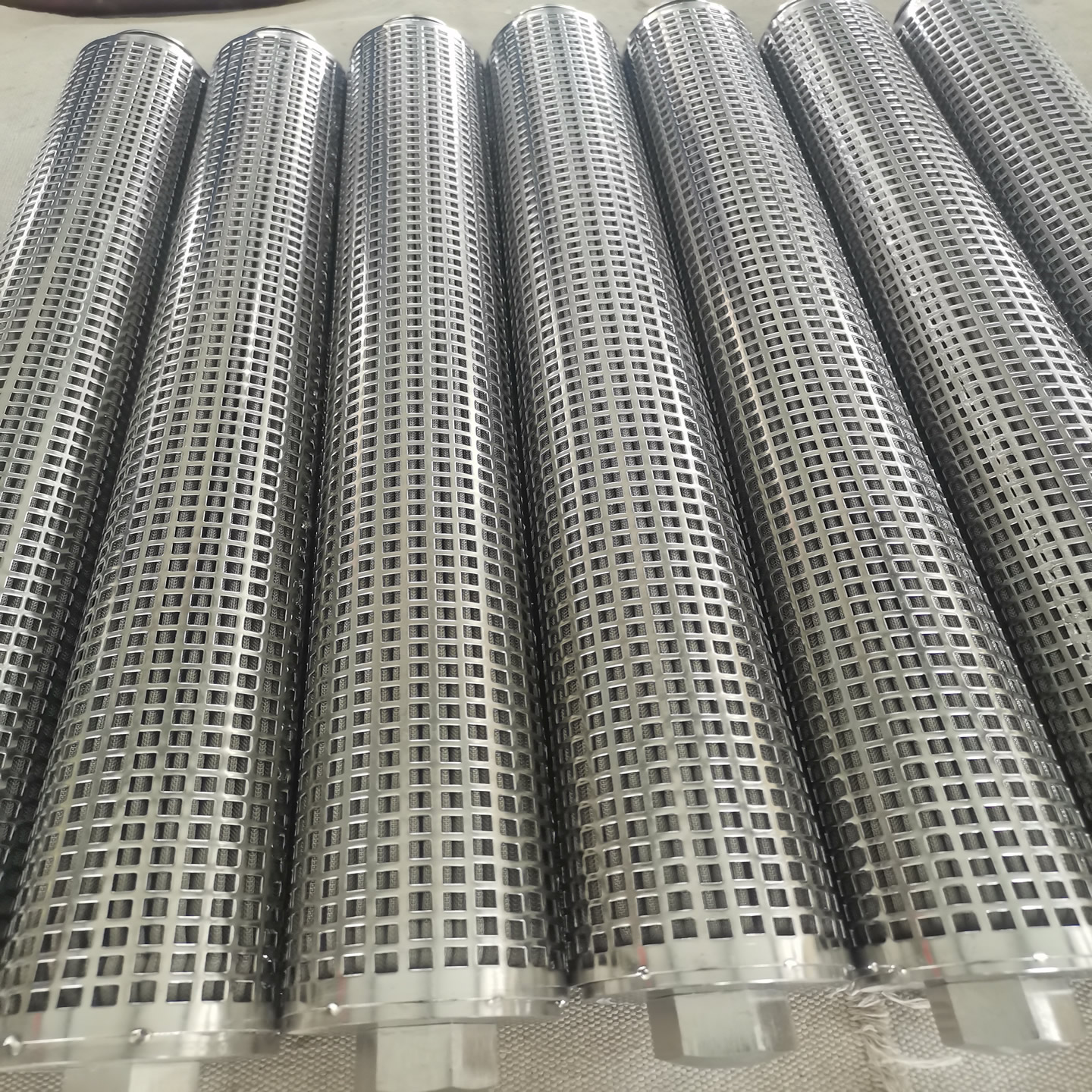

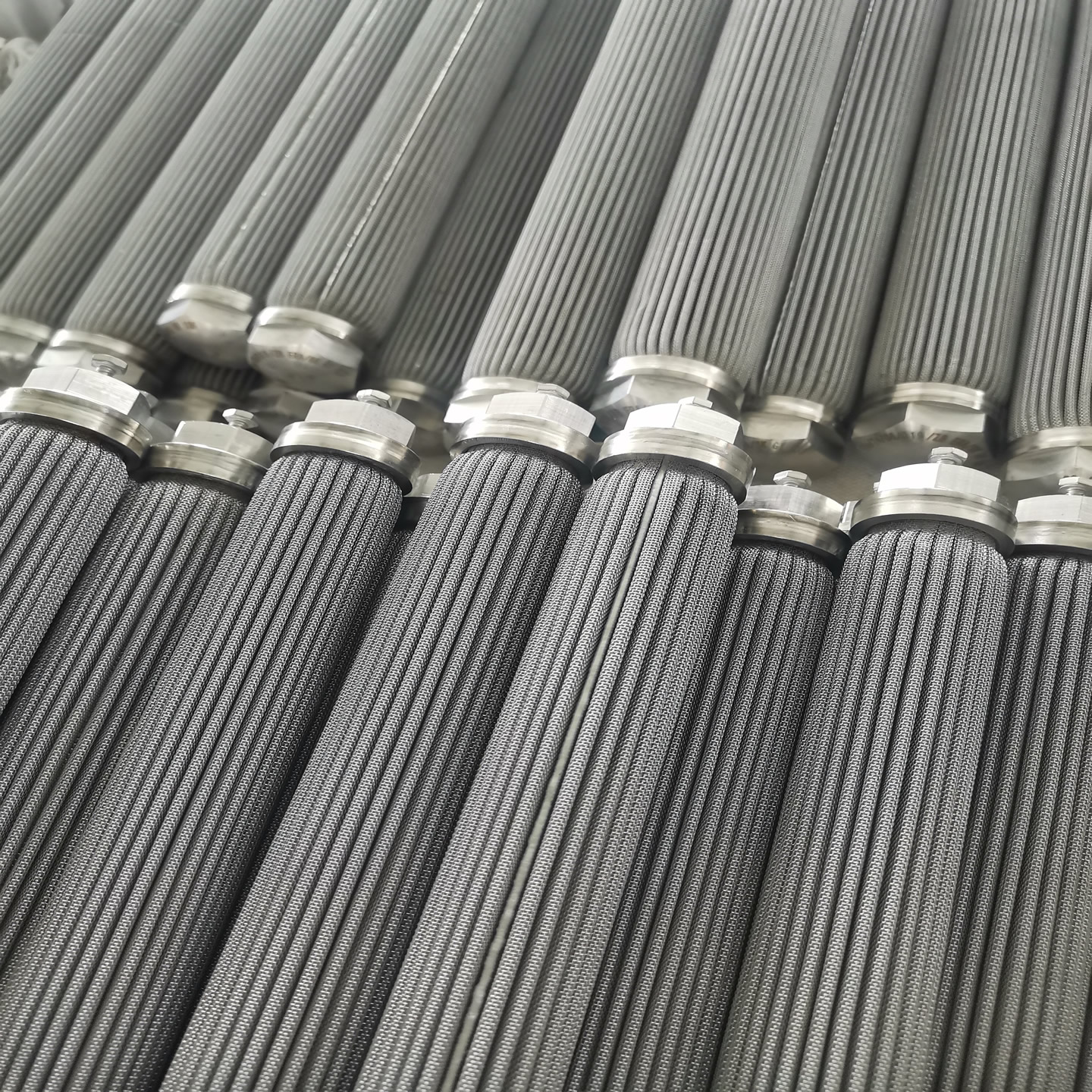

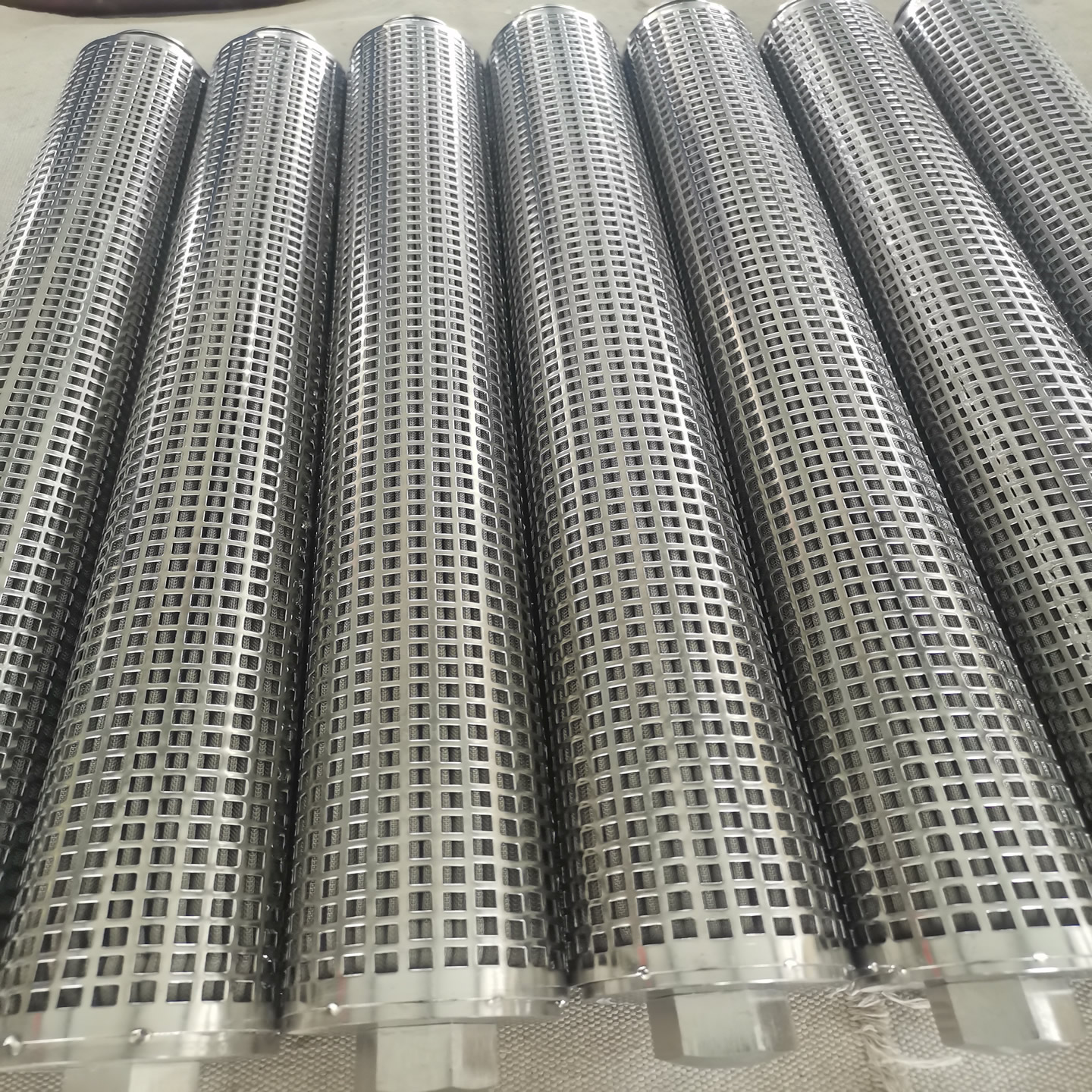

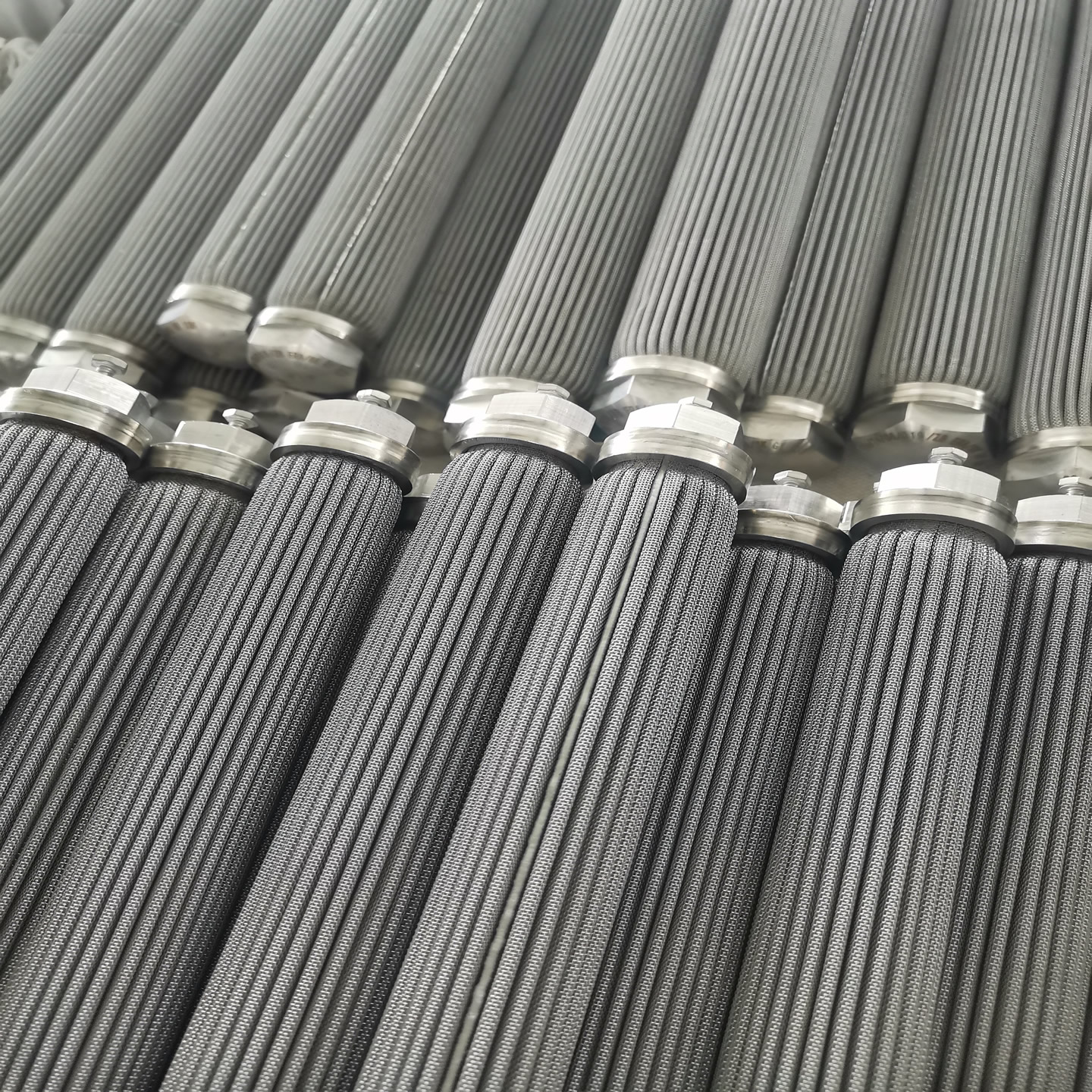

Fuel is easily contaminated with particles, rust, moisture, and other pollutants during transportation and storage. Stainless steel filter elements, with their fine pleated filter structure, effectively capture small particles (such as impurities from 0.5 to 50 microns), preventing contaminants from entering precision components like fuel injectors and high-pressure pumps. This helps avoid wear or blockages, thereby extending the lifespan of the equipment.

II. Strong Corrosion Resistance, Suitable for Various Fuel Environments

Fuels (such as diesel, gasoline, aviation fuel, biofuels, etc.) may contain sulfur compounds, acidic components, or additives. Ordinary filter materials can easily corrode and fail. Stainless steel filter elements, especially those made from 316L material, have excellent corrosion resistance and can withstand the chemicals in fuels for long-term stable filtration.

III.High Pressure and High-Temperature Resistance, Suitable for Harsh Conditions

In high-pressure common rail diesel systems or industrial fuel boilers, the fuel pressure may exceed 10 MPa, with significant temperature fluctuations. Stainless steel filter elements have high mechanical strength and can endure high-pressure impacts and temperatures (over 300°C) without deforming or breaking, ensuring safe system operation.

IV.Reusable, Reducing Maintenance Costs

Unlike disposable paper or fiber filters, stainless steel filter elements can be thoroughly cleaned using backwashing, ultrasonic cleaning, or solvent soaking, and reused hundreds of times. This significantly reduces the frequency of filter replacements and waste generation, making it especially suitable for large-scale fuel storage and transportation systems or continuous industrial production.

V.Prevention of Water and Microbial Contamination

Water in fuel can promote the growth of microbes (such as "diesel bacteria"), leading to filter clogging and fuel degradation. Stainless steel filter elements can be equipped with a water separation layer or centrifugal design to effectively remove water. Their smooth surface also resists microbial attachment, reducing the risk of biological contamination.

Ⅵ. Environmental Friendliness and Safety

Stainless steel filter elements do not have issues with material shedding, thus preventing secondary pollution. Additionally, the metal material is fire-resistant and static-free, making it safer in volatile, combustible fuel environments.

Typical Application Scenarios:

-

Automobile/Marine Fuel Systems: Protect fuel injectors and fuel pumps.

-

Aviation Fuel Filtration: Ensure the cleanliness of aircraft fuel.

-

Generator Sets/Industrial Boilers: Prevent burner clogging.

-

Oil Storage and Pipelines: Pre-treat fuel and extend the life of downstream equipment.

Conclusion:

Stainless steel filter elements play a vital role in fuel filtration, offering high-efficiency filtration, corrosion resistance, high-pressure tolerance, and reusability. These advantages make them a core component in ensuring fuel cleanliness and equipment reliability. Whether in precision power systems or large-scale industrial applications, stainless steel filter elements provide long-lasting, cost-effective filtration solutions.