Description

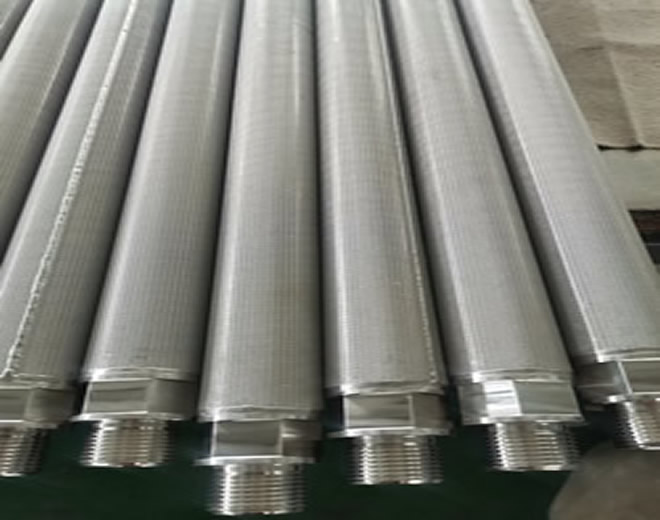

Overview of Stainless Steel Sintered Felt Filter Elements:

Stainless steel sintered felt filter elements are high-performance filtration components made using advanced metal fiber sintering technology. They are primarily composed of stainless steel fibers that are laid in a non-woven structure and then sintered at high temperatures to form a durable porous medium. With excellent air permeability, mechanical strength, and corrosion resistance, these filter elements are widely used in industries such as petrochemicals, hydraulics, pharmaceuticals, food processing, and environmental protection.

Structure and Material Characteristics

Stainless steel sintered felt typically uses 316L or 304 austenitic stainless steel as the base material. These materials are known for their high-temperature resistance and strong chemical stability. The sintered felt is formed by randomly laying stainless steel fibers of various diameters, which are then sintered into a three-dimensional porous mesh. The resulting structure features high porosity and uniform pore distribution, enabling efficient particle capture and deep filtration.

The filter elements can be fabricated into various shapes such as cylindrical, pleated, disc, or custom configurations to meet specific application requirements. They are highly designable and machinable.

Key Performance Features:

High Thermal Stability: Suitable for operating environments above 600°C, maintaining shape and performance over long-term use.

Excellent Mechanical Strength: High resistance to pressure and tensile forces, maintaining structural integrity under demanding flow or vibration conditions.

Washable and Reusable: Supports multiple cleaning methods such as backflushing, ultrasonic cleaning, and thermal cleaning, significantly extending service life.

Precise Filtration Accuracy: Available in a wide range of filtration ratings, typically from 3 to 100 microns, customizable based on specific filtration needs.

Strong Chemical Resistance: Withstands acid, alkali, and oxidation environments, making it suitable for various aggressive chemical processes.

Application Areas:

Petrochemical Industry: Used for catalyst recovery, oil purification, and solvent filtration.

Hydraulic Systems: Ensures long-term performance of hydraulic and lubrication systems by filtering fluids.

Pharmaceutical Industry: Provides sterile and clean filtration of liquids and gases.

Food and Beverage: Applied in fine filtration of wine, beverages, and edible oils.

Gas Purification: Ideal for gas separation and exhaust treatment.

Environmental Protection: Used in water treatment, solid-liquid separation, and related fields.

Installation and Maintenance Guidelines:

During installation, ensure all sealing points are secure to prevent leakage. Regular inspection is recommended to check for surface clogging or structural damage. Cleaning should be performed based on operating conditions, using appropriate methods compatible with both the process medium and the filter material to avoid damaging the metal fiber structure.