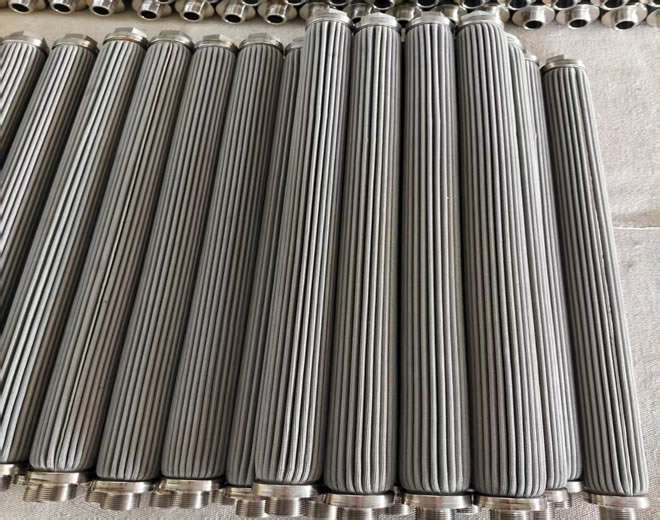

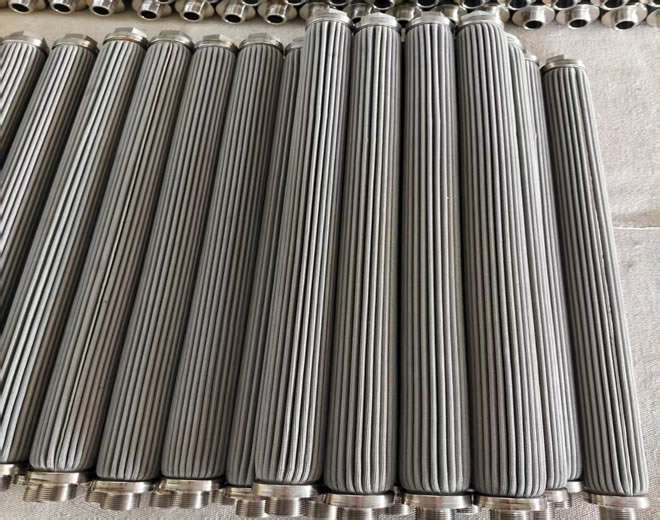

Description

Stainless Steel Filter Elements in Methanol Filtration: Role, Selection Criteria, and Application Scenarios

Stainless steel filter elements play a crucial role in methanol filtration. They are primarily used to remove solid particles, impurities, moisture, and other contaminants from methanol, ensuring its purity and meeting the stringent requirements of chemical, fuel, and pharmaceutical industries. Below is a detailed analysis of their functions, selection considerations, and typical applications:

1. Core Functions of Stainless Steel Filter Elements in Methanol Filtration

(1) Removal of Solid Particles

Filtration of mechanical impurities: During methanol production, storage, or transportation, contaminants such as rust, dust, and pipeline residues may be introduced. Stainless steel filters (typically with filtration accuracy ranging from 1 to 100 μm) can effectively trap these particles, protecting downstream equipment like pumps, nozzles, and reactors from abrasion or clogging.

Typical Applications: Methanol fuel injection systems, chemical raw material pretreatment.

(2) Separation of Water and Oil

Dehydration: Some stainless steel filter elements can be paired with hydrophilic or hydrophobic materials (e.g., multilayer sintered structures) to absorb trace moisture in methanol, which could otherwise affect chemical reactions or reduce fuel combustion efficiency.

Oil interception: If methanol comes into contact with lubricants or greases, the filter can block oil droplets to prevent contamination of the final product.

(3) Catalyst Protection

Catalyst safeguarding in chemical production: In processes such as Methanol-to-Olefins (MTO) or methanol synthesis, filter elements prevent catalyst poisoning by trapping particulates, thus extending catalyst lifespan.

(4) Compliance with Hygiene Standards

Pharmaceutical/Food-grade methanol: 316L stainless steel filters are corrosion-resistant and leach-free, complying with standards such as GMP and FDA, ensuring methanol’s safety for use in pharmaceuticals or food additives.

2. Key Selection Parameters

Material: 316L stainless steel is preferred due to its corrosion resistance, especially in the presence of trace acidic impurities. Avoid using carbon steel or standard 304 stainless steel, which may corrode over time.

Filtration Accuracy:

Fuel-grade methanol: 10–50 μm (to prevent nozzle clogging).

Electronic-grade methanol: ≤1 μm (often used with PTFE membrane layers).

Pressure Rating: Choose based on system pressure. For example, pre-filtering liquefied methanol before pumps may require a filter capable of ≥10 MPa.

Operating Temperature: Methanol boils at 64.7°C; for high-temperature applications (e.g., steam-traced pipelines), filters must withstand ≥100°C.

Design & Configuration: Flanged or threaded connections facilitate installation. Detachable filter elements allow easy cleaning and reuse.

3. Typical Application Scenarios

(1) Methanol Fuel Filtration

Methanol-gasoline blends (M85/M100): Filters remove particles and gum to protect vehicle fuel systems.

Methanol fuel cells: High-purity methanol is essential to prevent catalyst poisoning in fuel stacks.

(2) Chemical Industry

Methanol-to-hydrogen production: Filters remove sulfides and particulates to extend the life of reforming catalysts.

Formaldehyde production: Prevents rust and other impurities from entering oxidation reactors.

(3) Pharmaceutical Industry

Solvent-grade methanol purification: Removes microorganisms and particulates to meet pharmacopeia standards (e.g., USP) for solvent purity.

4. Maintenance and Precautions

Regular Replacement/Cleaning: When pressure drop reaches 0.3 MPa, the filter should be cleaned or replaced to avoid rupture and contamination.

Anti-static Design: Methanol is flammable—filters should be grounded or made of conductive materials to prevent static build-up.

Compatibility Testing: If methanol contains special additives (e.g., inhibitors), verify the chemical stability of the filter material.

5. Common Issues and Solutions

Issue 1: Rapid Filter Clogging

Cause: High impurity levels in methanol or overly fine filter accuracy.

Solution: Use staged filtration—e.g., a coarse filter (100 μm) followed by a main filter (10 μm).

Issue 2: Filter Corrosion

Cause: Acidic contaminants (e.g., formic acid) in methanol combined with non-316L filter materials.

Solution: Upgrade to corrosion-resistant materials or implement pretreatment (e.g., neutralization tower).