Description

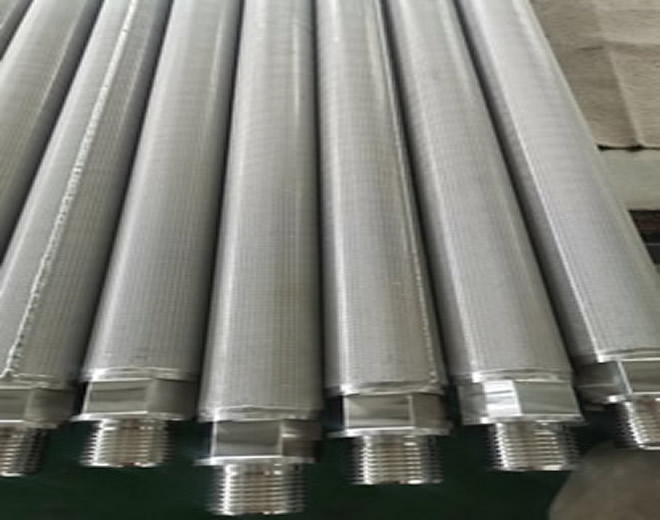

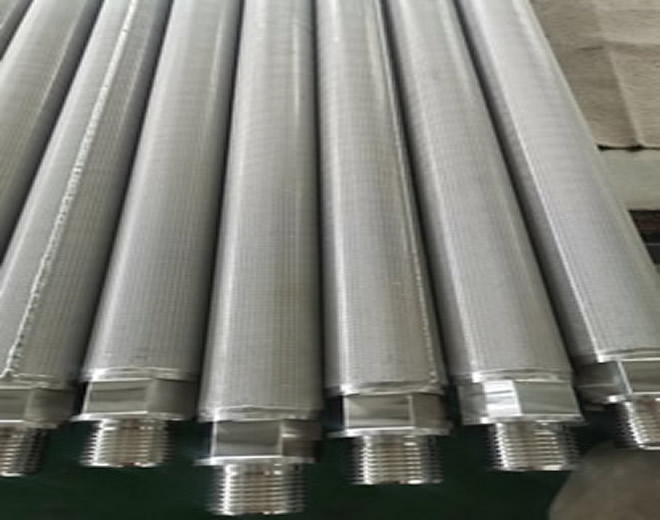

The stainless steel melt-blown filter cartridge is a commonly used industrial filter for liquid and gas filtration. Its core structure is made from stainless steel materials through a melt-blown process, offering excellent strength, high-temperature resistance, and chemical stability. Melt-blown filters are often used in high-temperature, high-pressure filtration scenarios, such as in petrochemical, food, pharmaceutical, and gas purification industries.

1. Structure and Features of Melt-blown Filter Cartridges

Filter Cartridge Structure:

Stainless Steel Material: Made from high-quality stainless steel such as 304 or 316L, which ensures high corrosion resistance and high-temperature tolerance, ensuring the filter cartridge performs well in harsh environments.

Melt-blown Process: The metal wires or alloys are processed into a porous structure through the melt-blown technique, which provides high filtration efficiency and low pressure drop.

Layered Structure: Stainless steel melt-blown filter cartridges are typically composed of multiple layers of fibers with varying filtration precision, which allow the filter to capture solid particles of different sizes progressively during filtration.

Features:

High strength and pressure resistance, suitable for use under high-pressure, high-temperature conditions.

Able to withstand higher chemical corrosion, making it ideal for extreme environments.

High filtration precision, typically ranging from 1 micron to 200 microns, meeting different industrial requirements.

2. Filtration Principle

The filtration principle of stainless steel melt-blown filter cartridges is primarily based on physical retention and depth filtration mechanisms. Specifically, the filtration process can be broken down into several steps:

Surface Filtration:

When liquid or gas flows into the melt-blown filter cartridge, larger particulate contaminants are first captured by the surface fibers. These larger particles accumulate on the surface of the filter, forming the first barrier that prevents them from passing through.

Depth Filtration:

The unique feature of melt-blown filters is their deep-layer structure. As the liquid or gas passes through the filter, the smaller particles are further captured by the internal layers of the filter. The fiber structure, made from stainless steel wire or alloy materials, provides strong mechanical retention, ensuring even the smallest particles are effectively filtered out.

Adsorption:

During the filtration process, some fine particles will adhere to the metal fibers through electrostatic attraction, enhancing the filter's filtration capacity. This adsorption effect significantly improves the filter's ability to capture fine particles, making it particularly effective for handling very small contaminants.

Depth Deposition Filtration:

As filtration progresses, the surface of the filter gradually accumulates particles. However, due to its deep-layer structure, this accumulation does not impact the filter's efficiency. Instead, the accumulated particles enhance the filtration layer's performance, creating a more effective filtration barrier.

3. Filtration Efficiency and Applications

The filtration efficiency of stainless steel melt-blown filter cartridges depends on their pore structure and material selection. Common filtration precision ranges from 1 micron to 100 microns, meeting the filtration precision requirements for most industrial fields.

High-Precision Filtration: Effectively removes fine particles, impurities, and microorganisms from liquids and gases.

High Temperature and Pressure Resistance: Suitable for removing solid particles in high-temperature and high-pressure environments, widely used in petrochemical, pharmaceutical, and food industries.

Long Service Life: Due to its corrosion resistance and high-temperature tolerance, the melt-blown filter cartridge has a long service life and can be cleaned repeatedly, reducing the need for frequent replacements.

4. Conclusion

Stainless steel melt-blown filter cartridges are high-performance, reliable industrial filtration components with excellent strength, high-temperature, and corrosion resistance. Their filtration principle, based on physical retention, depth filtration, and adsorption, allows them to effectively remove various particulate contaminants. Whether used in liquid or gas filtration, these filters deliver exceptional performance, especially in industrial environments that demand high precision, strength, and durability.