Description

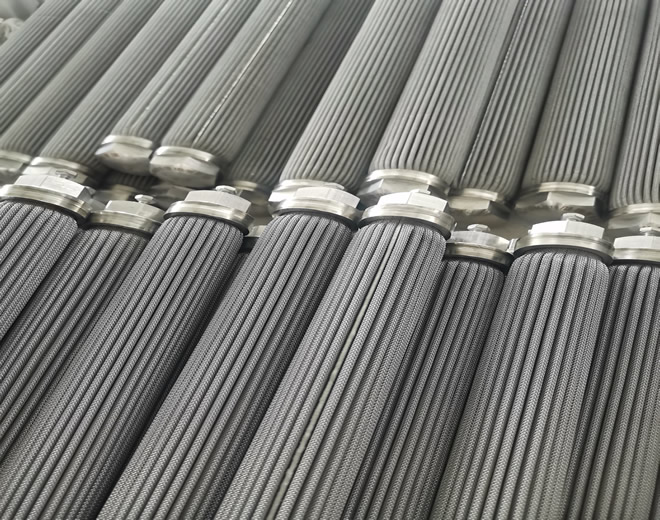

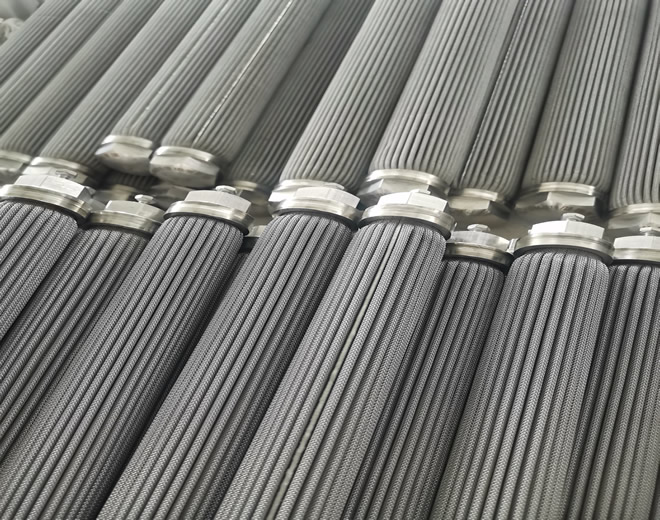

A metal pleated filter element is a type of filter commonly used for liquid and gas filtration, particularly in high-temperature, high-pressure, and corrosive environments. Its core feature is the special pleated design, which enhances filtration performance and fluid dynamics.

Filtration Principle of Metal Pleated Filter Elements:

The working principle of a metal pleated filter element is based on physical retention and depth filtration, where the special metal structure captures solid particles, impurities, and contaminants in the fluid. Specifically, the filtration mechanism can be broken down into several key points:

1. Mechanical Screening: The metal pleated filter element typically consists of multiple layers of metal mesh, woven from wires with varying pore sizes. As the fluid flows through the filter, larger particles and impurities are directly trapped by the mesh and cannot pass through. This process acts as a "screen" to primarily capture larger particles.

2. Depth Filtration: The pleated structure of the metal filter provides a larger surface area and more complex flow paths compared to traditional flat mesh filters. This design allows the fluid to spend more time in contact with the filter, allowing smaller particles to be captured deeper within the filter media. This not only improves filtration accuracy but also increases the filter's dirt-holding capacity.

3. Expanded Filtration Area: The pleated structure creates a wave-like shape in the filter, significantly increasing the filtration surface area. This increases the filter's ability to handle more fluid and operate for longer periods without clogging, all while maintaining the same overall filter size.

4. Surface Adsorption and Accumulation: In addition to mechanical screening and depth filtration, the metal filter surface may adsorb fine particles from the fluid, further improving the filtration effect. This is especially noticeable when filtering complex fluids such as oils or chemicals.

5. Self-Cleaning Capability: Due to the material and structural characteristics of metal filters, many metal pleated filters have self-cleaning capabilities. Under high pressure or during reverse flushing, the fluid can help remove contaminants from the filter surface, extending the filter's lifespan and reducing maintenance costs.

Advantages of Metal Pleated Filter Elements:

1. High Temperature and Pressure Resistance: Metal pleated filter elements can withstand high-temperature and high-pressure environments, making them suitable for a wide range of harsh operating conditions.

2. Chemical Stability: Metals like stainless steel have good corrosion resistance in most chemical environments, making them suitable for filtering acids, alkalis, oils, and other corrosive liquids and gases.

3. High Strength: Metal filters have excellent structural integrity, enabling them to handle high flow rates and high-pressure applications.

4. Washable and Reusable: Due to their durability, metal pleated filter elements can be cleaned and reused, reducing the frequency of filter replacement.

5. High Filtration Precision: With fine metal mesh and pleated design, they offer high filtration precision, efficiently removing fine particles and impurities.

Applications of Metal Pleated Filter Elements:

Metal pleated filters are widely used in the following industries:

1.Oil and Gas Industry: Used for filtering crude oil and natural gas, removing solid contaminants and ensuring smooth operation of equipment.

2.Chemical and Pharmaceutical Industry: Used for filtering chemicals, solvents, and other liquids to maintain purity during production processes.

3.Food and Beverage Industry: Used for filtering oils, syrups, beverages, and other fluids to ensure product quality.

4.Water Treatment and Wastewater Treatment: Used for removing contaminants, sand, and suspended particles from water.

5.Hydraulic Systems: Protects hydraulic pumps and other precision equipment from solid particle damage.