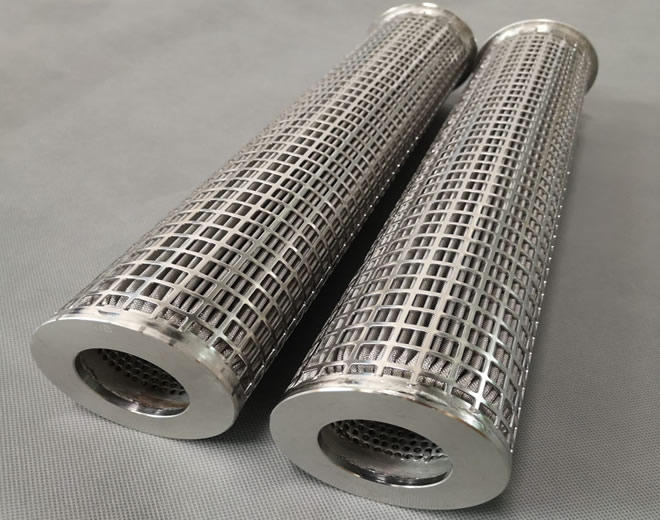

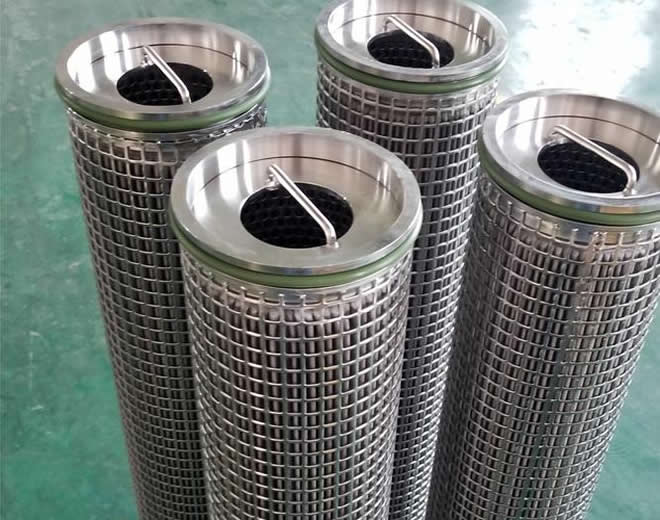

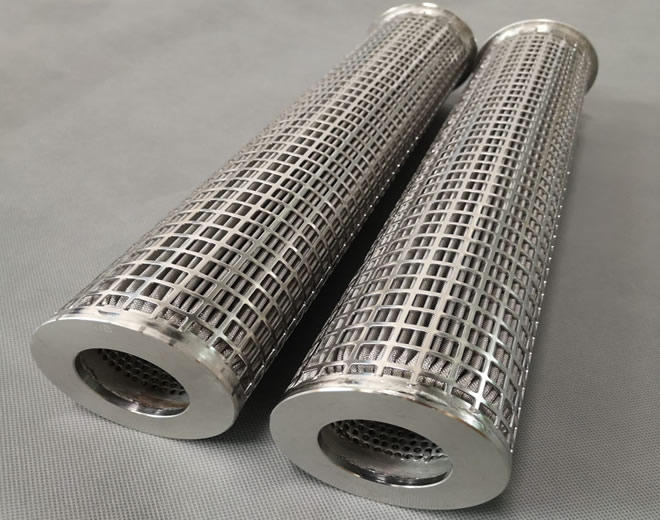

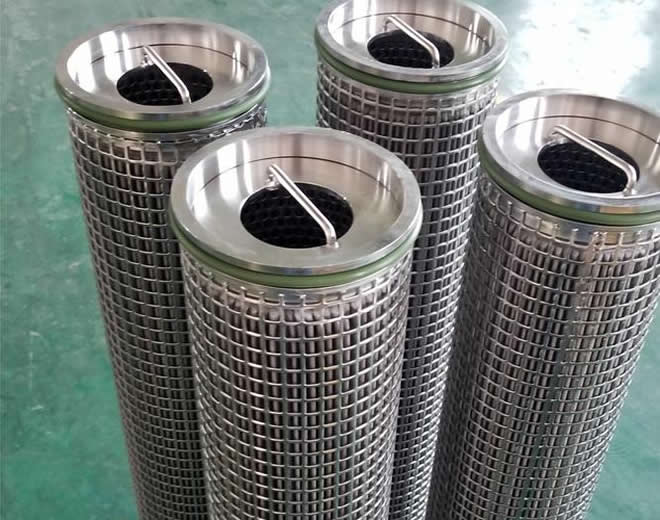

Stainless steel melt filter elements are high-performance filtration components specially designed for high-temperature and high-viscosity fluid applications. They are widely used in polymer melt filtration, chemical processing, lubricants, coatings, and other demanding environments. Made from durable stainless steel materials, these filters offer excellent thermal resistance, corrosion resistance, and mechanical stability, making them ideal for advanced melt filtration systems.

Stainless steel melt filter elements are typically constructed from sintered wire mesh, stainless steel fiber felt, or metal powder using forming, welding, and sintering techniques. Common structural types include:

Multi-layer sintered mesh: Composed of multiple layers of woven metal mesh sintered at high temperatures, providing uniform and stable porosity.

Cylindrical or pleated design: Offers increased filtration surface area and enhanced efficiency.

Reinforced inner and outer support structure: Ensures mechanical stability under high differential pressures.

Stainless steel melt filters operate through a combination of surface filtration and depth filtration:

Surface interception: Large particles are trapped on the outer surface.

Pore filtration: Fine particles enter the internal porous layers and are gradually captured.

Deep trapping: Interwoven fibers or micropores enable high-efficiency retention of ultra-fine contaminants.

This layered filtration approach results in high dirt-holding capacity and extended service life.

High temperature resistance: Operates stably at temperatures up to 600°C.

Excellent corrosion resistance: Suitable for acids, alkalis, and various chemical media.

High mechanical strength: Resists collapse and deformation under pressure.

Reusable: Supports multiple cleaning methods including backflushing and ultrasonic cleaning.

High filtration precision: Filtration rating from 1 to 50 microns with uniform pore size distribution.

Stable structure: Maintains shape and performance under extreme conditions.

Stainless steel melt filter elements are widely used in:

Polymer melt filtration: For PET, PP, PE, PS, and other thermoplastic materials.

Coatings and inks: Precision filtration of high-viscosity liquids and pigment pastes.

Petrochemical industry: Filtration of lubricants, fuel oils, thermal oils, etc.

Food and pharmaceutical: Steam or fluid filtration in high-temperature, hygienic environments.

Synthetic fiber industry: Pre-spinning melt filtration processes.

To ensure optimal performance and lifespan, regular cleaning and maintenance are recommended. Common cleaning methods include:

Ultrasonic cleaning

Thermal treatment (burn-off for polymer residues)

Chemical soaking (with appropriate solvents)

In-line backflushing (depending on system design)

If the filter shows persistent clogging or high pressure drop after cleaning, timely replacement is necessary.

With outstanding durability, filtration efficiency, and resistance to harsh conditions, stainless steel melt filter elements are essential in modern industrial filtration. As materials and manufacturing technologies advance, these filters will continue to improve in performance and help meet ever-increasing industry standards.