Description

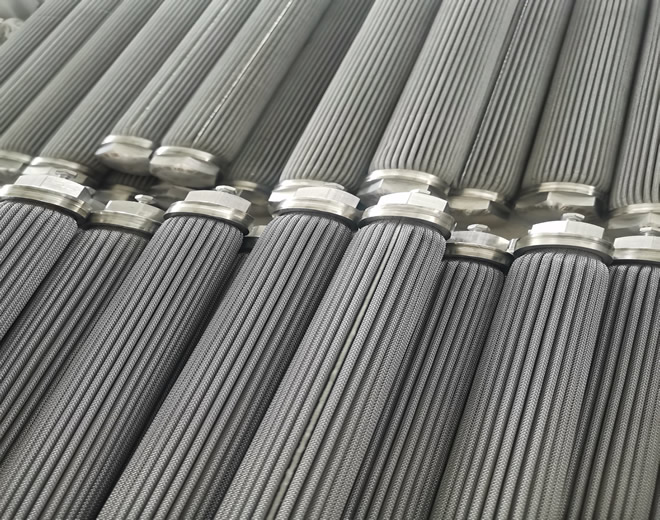

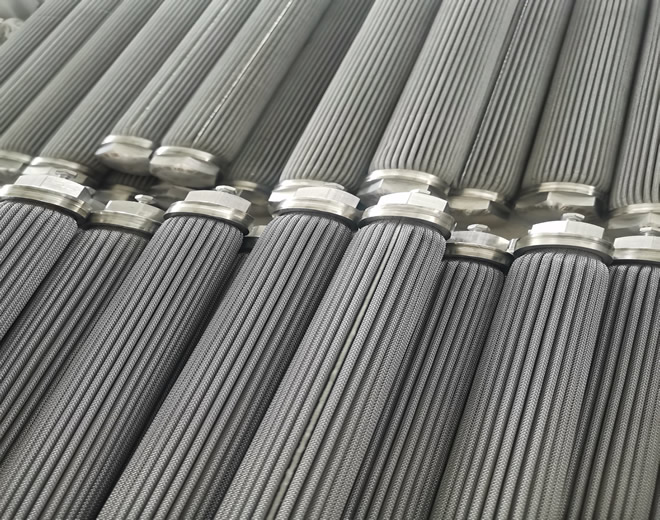

Stainless steel melt filter elements for chemical fiber production are high-performance filtration components specifically designed for the purification of high-temperature polymer melts such as PET, PP, PA, and other synthetic fibers. Their main function is to remove impurities, gels, and unmelted particles from the polymer melt, ensuring stable spinning performance and high-quality fiber output. Constructed from high-strength stainless steel, these filter elements offer exceptional thermal resistance, corrosion resistance, and structural integrity, making them a vital part of modern fiber production systems.

1. Structure & Materials

Stainless steel melt filter elements are commonly made using one or more of the following materials:

-

Sintered stainless steel mesh: Multi-layer woven metal mesh sintered at high temperatures, providing uniform pore distribution and excellent mechanical strength.

-

Stainless steel fiber felt: Manufactured through sintering fine stainless steel fibers, offering outstanding deep filtration performance.

-

Sintered metal powder: Made from stainless steel powder processed under high temperatures to form a microporous filter medium.

-

Filter elements come in various shapes and configurations such as cylindrical, pleated, cartridge, disc-type, or customized structures based on melt flow rate and equipment type.

2. Filtration Principle

These filters utilize a combination of surface filtration and depth filtration mechanisms:

-

Surface filtration: Larger particles are intercepted at the outer layer of the filter.

-

Depth filtration: Finer impurities are gradually captured within the multi-layer filter structure.

-

Progressive purification: Ensures highly pure melt output, preventing spinneret clogging and fiber breakage.

3. Key Performance Features

-

Excellent high-temperature resistance: Operates reliably in melt temperatures ranging from 300°C to 600°C.

-

Superior mechanical strength: Resists collapse or deformation under high differential pressure.

-

High filtration precision: Standard ratings range from 5 to 50 microns; customizable upon request.

-

Reusable and cleanable: Supports thermal cleaning, ultrasonic cleaning, and chemical soaking for extended service life.

-

Flexible installation: Compatible with various fiber production filter housings and custom-built systems.

-

Chemical resistance: Withstands harsh chemical conditions in polyester, nylon, polypropylene, and other polymer melts

4. Typical Applications

-

PET (polyester) melt filtration for fiber spinning

-

PP (polypropylene) melt filtration for short and long fiber lines

-

PA (nylon) melt purification for high-tenacity fibers

-

Recycled polymer melt filtration in post-consumer fiber processing

-

Precision filtration in fine denier and specialty fiber production

5. Maintenance & Replacement Guidelines

To maintain optimal filtration performance:

-

Monitor pressure drop across the filter regularly.

-

Replace or clean the filter when pressure drop increases or spinning anomalies occur.

-

Use thermal cleaning ovens, ultrasonic tanks, or chemical solutions for periodic maintenance.

-

Implement scheduled filter rotation to extend overall service life.

6. Conclusion

Stainless steel melt filter elements are essential for achieving high-purity polymer melt filtration in the chemical fiber industry.

With outstanding durability, precision, and thermal stability, they ensure consistent fiber quality and equipment reliability.

As synthetic fiber technology continues to evolve, stainless steel melt filters will play an increasingly critical role in enabling high-performance,

efficient, and sustainable fiber manufacturing.