Description

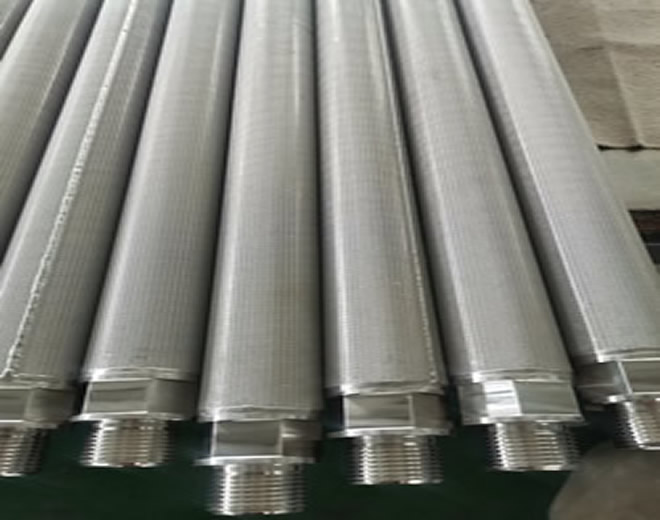

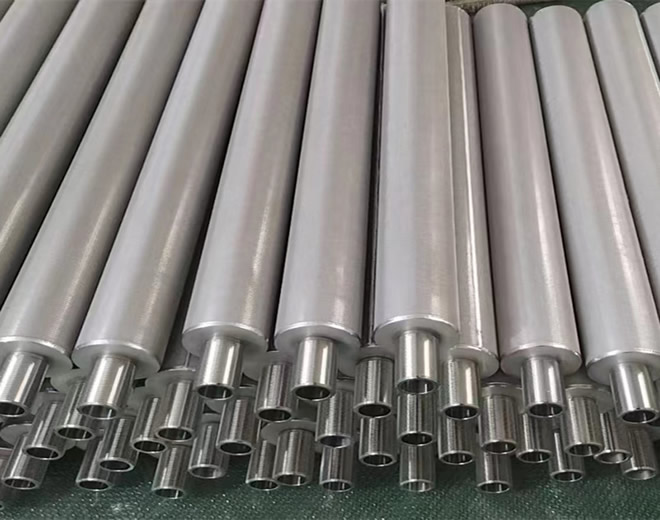

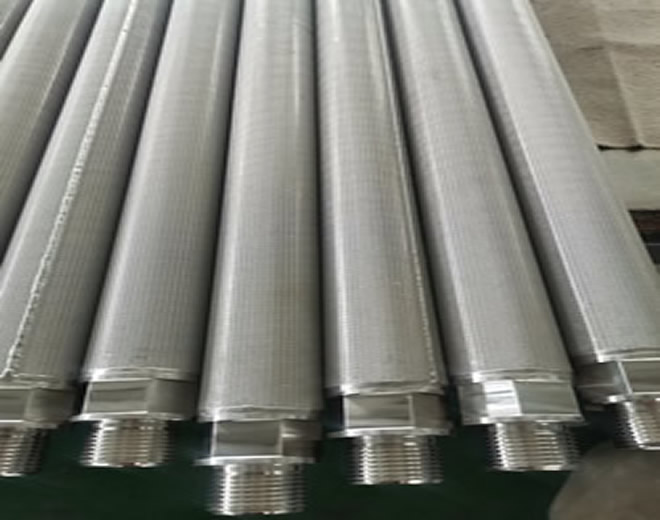

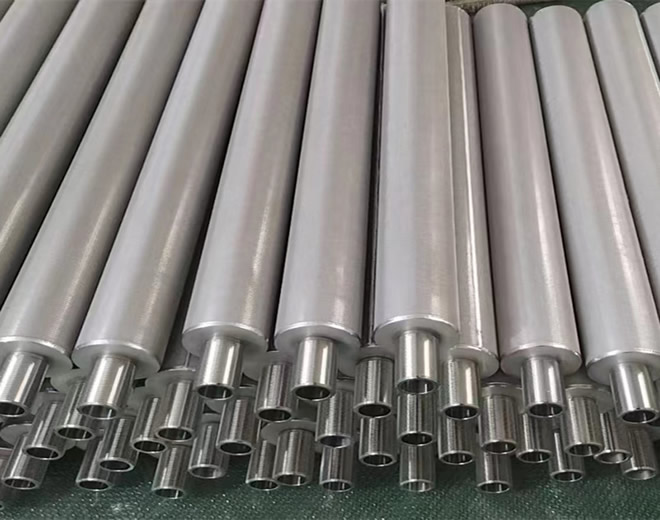

Methanol Sintered Mesh Filter Cartridge Introduction

The methanol sintered mesh filter cartridge is a high-performance metal filter element specially designed for filtering methanol and related chemical media.

Its core material is multi-layer stainless steel sintered wire mesh, manufactured through a high-temperature vacuum sintering process.

This process bonds multiple layers of stainless steel wire mesh into a single, solid structure with uniform and stable pores,

ensuring excellent mechanical strength and filtration performance even under high temperature, high pressure, and corrosive environments.

1. Structure & Materials

Materials: Commonly made of stainless steel 304, 316L, or duplex stainless steel 2205. Titanium, Hastelloy, and other corrosion-resistant alloys can be customized according to the medium.

Structure: Typically composed of a protective layer, dispersion layer, precision filtration layer, and support layer. These layers are stacked and sintered to form a strong, integrated filter medium.

Shapes: Available in cylindrical, pleated, cartridge, and disc forms to suit various installation requirements.

2. Filtration Principle

The methanol sintered mesh filter cartridge combines surface filtration with depth filtration:

Surface Filtration: The precision filtration layer with uniform pore size effectively traps larger solid particles.

Depth Filtration: The multi-layer mesh structure intercepts and adsorbs fine suspended particles, water, and colloids, ensuring high methanol purity.

3. Key Features

High Temperature & Pressure Resistance: Suitable for filtration environments above 200 °C and several MPa of pressure.

Excellent Corrosion Resistance: Withstands long-term exposure to methanol and methanol mixtures.

High Strength & Structural Stability: Sintered construction prevents cracking, deformation, or media shedding.

Cleanable & Reusable: Supports backwashing, ultrasonic cleaning, and chemical cleaning for extended service life.

Consistent Filtration Accuracy: Uniform pore size ensures stable filtration from 1 μm to 100 μm, unaffected by pressure fluctuations.

4. Applications

Methanol sintered mesh filter cartridges are widely used in:

Methanol Production & Purification: Removing solid impurities and moisture to ensure purity.

Chemical Processing: Circulation filtration when methanol is used as a solvent or raw material.

Fuel Industry: Purification of methanol fuel or methanol-gasoline blends.

Pharmaceutical & Fine Chemicals: Ensuring purity and stability of process methanol.