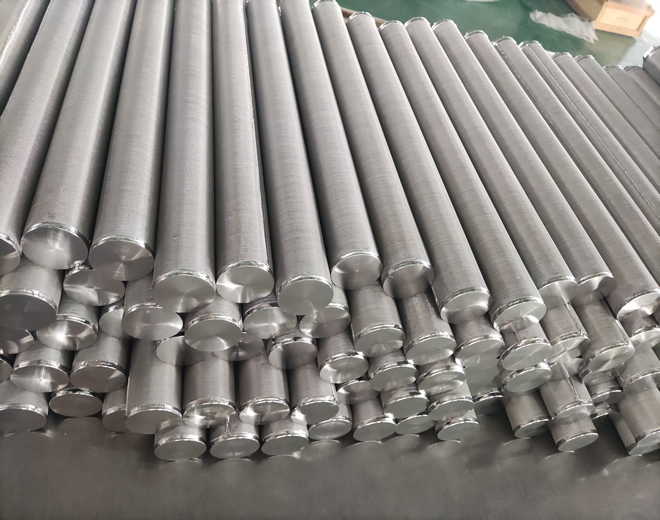

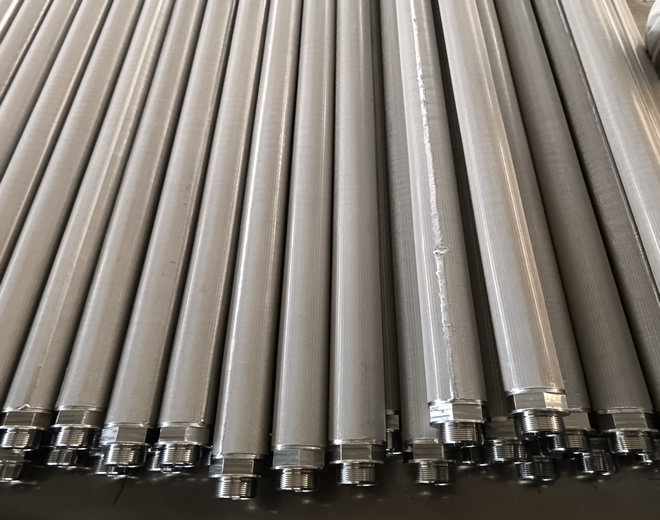

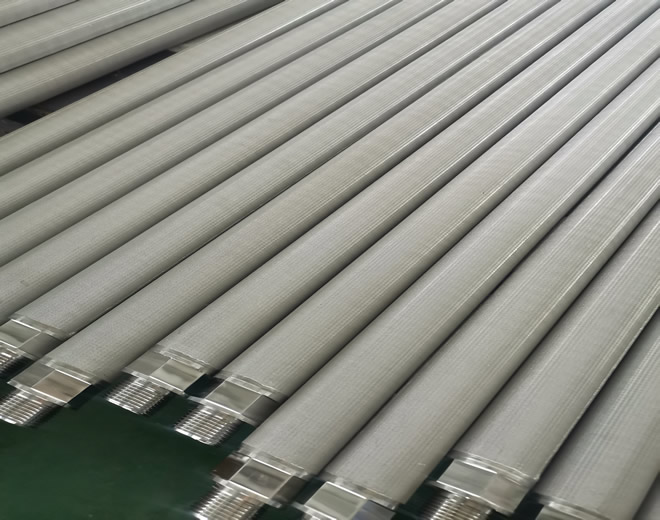

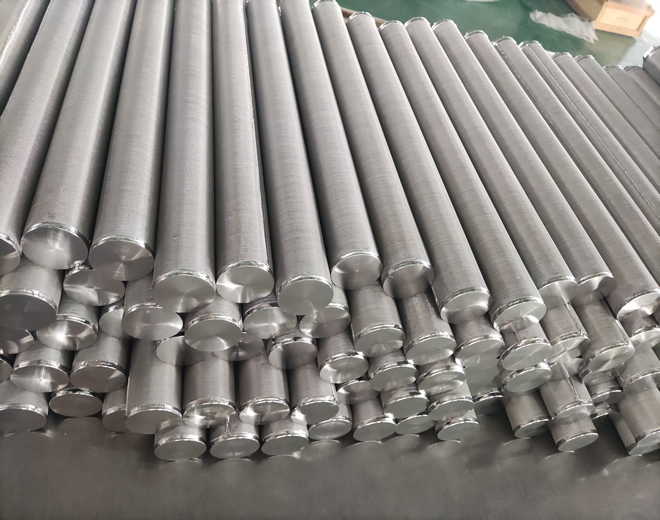

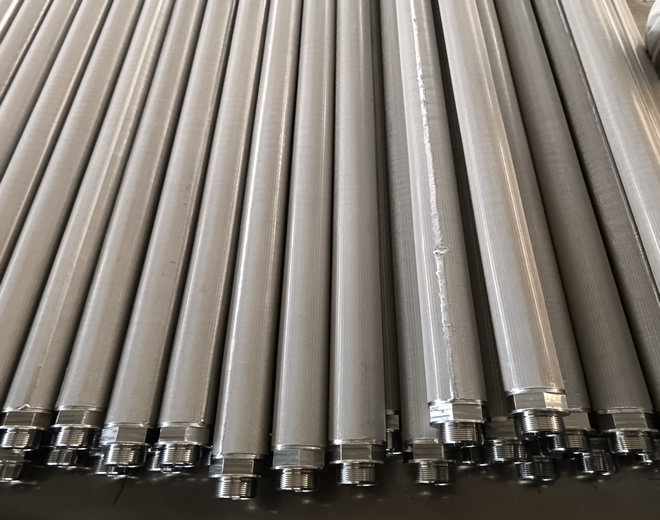

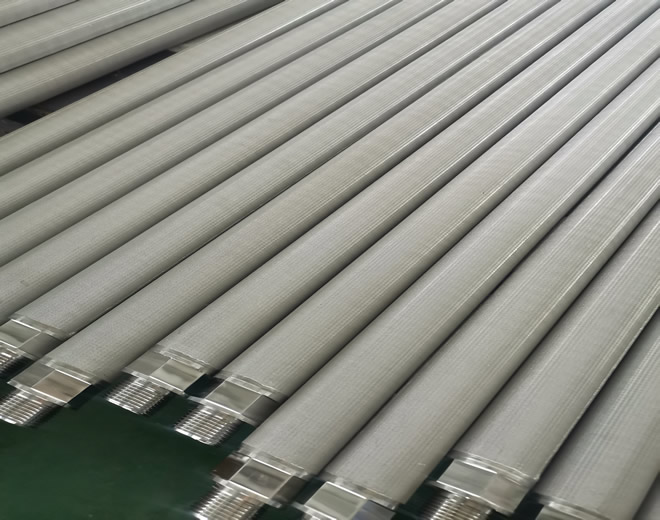

The metal sintered mesh filter element is a porous filtration material made by laminating multiple layers of metal woven mesh and bonding them through high-temperature sintering.

Its unique structure provides high strength, high precision, and excellent permeability, making it widely applicable for solid-liquid and gas-solid separation in high-temperature,

high-pressure, and corrosive environments. It is a core component in industrial filtration systems.

Protective Layer: Resists external impact and prevents damage to the filtration layer.

Precision Control Layer: Determines filtration accuracy with uniform and stable pores.

Dispersion Layer: Distributes fluid pressure evenly, preventing local clogging.

Reinforcement Layers (two layers): Provide mechanical support and enhance pressure resistance.

These layers are interlaced to form a uniform filtration structure, ensuring an optimal balance between accuracy and strength.

Conducted under high-temperature vacuum conditions.

Metal meshes are diffusion-bonded into a solid structure without adhesives or welds, eliminating secondary contamination risks.

Process parameters (temperature, duration, vacuum level) are precisely controlled to ensure stable porosity, permeability, and mechanical properties.

Pressure Resistance: Withstands hundreds of kilograms of pressure, suitable for high-pressure backwash systems.

Impact Resistance: Five-layer structure distributes stress, preventing deformation or rupture.

Fatigue Resistance: Maintains structural stability over long-term use, with a lifespan far exceeding traditional filter media.

Filtration Range: 2–200 μm, covering micro- to coarse filtration needs.

Surface Filtration Mechanism: Impurities are trapped on the surface, making the filter easy to clean by backflushing or ultrasonic cleaning.

Low Resistance: High porosity (typically >30%) ensures high flow capacity and reduced energy consumption.

Temperature Resistance: Operates from –200°C to 650°C, suitable for cryogenic and high-temperature applications (e.g., steelmaking, petrochemicals).

Corrosion Resistance: Commonly made from 316L stainless steel, resistant to strong acids, alkalis, and organic solvents.

Wear Resistance: High hardness metal mesh is suitable for long-term filtration of particle-laden media.

Petrochemicals

Filtration of corrosive liquids (e.g., pickling solutions, catalyst recovery).

High-pressure oil backwash systems, extending equipment service cycles.

Pharmaceutical & Food Industries

Sterile material filtration, meeting GMP requirements.

High-temperature steam sterilization without chemical residues.

New Energy & Environmental Protection

Ultrapure water filtration in semiconductor manufacturing.

Gas turbine intake filtration, preventing blade erosion by particles.

Mechanical & Hydraulic Systems

Precision hydraulic oil filtration to protect pumps and valves.

Polymer melt purification in chemical fiber production, ensuring fiber uniformity.

| Feature | Metal Sintered Mesh Filter | Powder Sintered Filter | Fiber Felt Filter |

|---|---|---|---|

| Structure | Five-layer mesh, regular pores | Randomly packed powder, uneven pores | Interlaced fibers, pores easily deformed |

| Filtration Stability | High (fixed mesh openings) | Medium (dependent on powder particle size) | Low (collapses under pressure) |

| Pressure Resistance | Very High (>50 bar) | High (20–50 bar) | Low (<10 bar) |

| Regeneration Ability | Excellent (>95% backwash efficiency) | Moderate (requires chemical cleaning) | Poor (easily damaged) |

| Cost | Medium-High (long lifespan offsets cost) | Low (mostly disposable) | Low (frequent replacement needed) |

Standard Conditions: 316L stainless steel (high cost-performance).

Strong Corrosion Environments: Hastelloy C-276, Monel 400.

High-Temperature Applications: Inconel 600, Duplex Steel 2205.

Coarse Filtration (50–200 μm): Protects downstream equipment, extends fine filter lifespan.

Fine Filtration (2–50 μm): Directly captures fine particles, meeting end-quality requirements.

Dimensions: Seamless forming up to 1500 mm, suitable for large-scale filters.

Interfaces: Supports standard fittings, flanges, threads, compatible with existing systems.

Shapes: Available in round, square, or custom shapes to fit special installations.

Cleaning Cycle

Triggered by pressure drop increase (typically ΔP ≥ 0.5 bar) or by schedule (e.g., every 24 hours) for backwashing.

Chemical cleaning: once per month, using citric acid or sodium hydroxide solutions.

Service Life Assessment

Initial pressure drop: should be <0.1 bar for new filters.

Pressure rise rate: if increase >0.2 bar per month, inspect filter integrity.

Visual inspection: check for clogging or damage to mesh regularly.

The metal sintered mesh filter element, with its high strength, precision stability, and resistance to extreme environments, has become the preferred choice in petrochemicals, pharmaceuticals, new energy, and other industries. Through proper selection and routine maintenance, it can significantly reduce lifecycle costs and enhance overall system reliability.