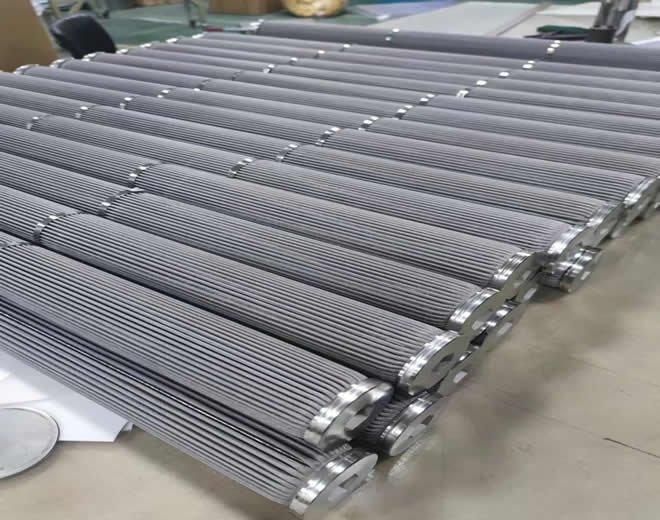

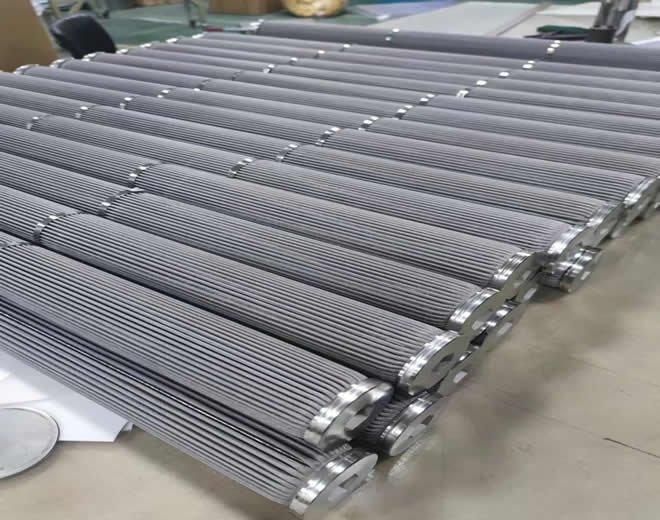

A metal sintered felt filter cartridge is a high-performance, porous material constructed from extremely fine metallic fibers (typically stainless steel 316L, 304, Hastelloy, or Inconel). These fibers are layered, assembled, and fused together using a high-temperature vacuum sintering process to form a rigid, three-dimensional porous network structure.

Analogy:

A traditional woven wire mesh is a two-dimensional "sieve" with fixed openings.

A metal powder sintered filter is three-dimensional but with more tortuous and potentially less uniform pores.

A metal sintered felt combines the best of both: it resembles a incredibly robust and permanent "steel wool" pad, with a continuous, gradient-pore, 3D structure.

High Porosity & High Dirt Holding Capacity: With a porosity of 75%-85%, its intricate internal structure can effectively capture and hold a large amount of contaminant. This leads to a long service life and a slow rise in pressure drop.

Excellent Filtration Rating: Offers a broad filtration range, typically from 5μm to 200μm. It provides absolute filtration, reliably retaining all particles larger than its rated pore size.

Outstanding Material Resistance:

High-Temperature Resistance: Can operate continuously at temperatures above 500°C (932°F) and withstand short-term exposure up to 600-700°C (1112-1292°F).

Corrosion Resistance: Material can be selected for compatibility with the fluid (e.g., 316L offers excellent resistance to many acids and alkalis).

Abrasion Resistance & High Strength: The metallic construction withstands high flow velocities and particle impingement, offering far greater mechanical strength than paper, cloth, or polymer filters.

Excellent Cleanability & Reusability: The stable structure allows for thorough cleaning and regeneration via high-temperature burn-off (500°C), ultrasonic cleaning, chemical cleaning, or backflushing. This reusability significantly reduces operating costs.

No Media Migration: As a monolithic sintered metal structure, it will not shed fibers like textile filters, ensuring downstream fluid cleanliness—a critical feature for high-purity applications.

Consistent Performance: Unlike polymer membranes, it does not age, hydrolyze, or degrade, ensuring stable performance over time.

Fiber Production: Micron-scale metal fibers are produced through processes like melt spinning or wire drawing.

Layering (Web Formation): Fibers of different diameters are layered in a gradient structure. Typically, finer fibers are on the outer layers for high precision, while coarser fibers in the core provide high dirt capacity and structural support.

Sintering: The layered "felt" is heated in a high-temperature vacuum furnace. The fibers bond at their points of contact through diffusion bonding, creating a single, rigid solid without melting the entire structure.

| Feature | Metal Sintered Felt Cartridge | Metal Sintered Powder Cartridge |

|---|---|---|

| Structure | 3D fibrous network, highly permeable | Powder particles, more tortuous pores |

| Dirt Holding Capacity | Very High (deep-bed filtering) | Moderate |

| Permeability/Flow Rate | Superior (higher porosity, lower resistance) | Good |

| Strength & Toughness | High, some flexibility | Brittle |

| Filtration Rating | Broad, typically 5-200μm | Broad, can achieve higher precision (e.g., 0.1μm) |

| Cleanability/Reusability | Excellent, easy to backflush | Good, but may have fewer regeneration cycles |

| Cost | Higher | Lower |

Summary: Sintered felt excels in high dirt loading, high flow, and long life applications. Sintered powder is often better for achieving the highest possible precision ratings but with lower dirt capacity.

These filters are critical in demanding industries where reliability is paramount:

Petrochemical Industry:

Polymer melt filtration (e.g., polyester, nylon).

Filtration of hot fuel, lubricating, and hydraulic oils.

Catalyst recovery.

Chemical Processing:

Precision filtration of strong acids, alkalis, and organic solvents.

Chemical product purification.

Pharmaceutical & Biotech:

Sterilizing filtration of APIs (Active Pharmaceutical Ingredients) and Water for Injection (WFI) (must be GMP compliant).

Sterile air filtration for fermenters.

Food & Beverage Industry:

Hot clarification of beer, wine, juices, and edible oils.

Electronics Industry:

Point-of-use filtration of high-purity gases (e.g., N₂, Ar) and ultra-pure chemicals.

Environmental & Nuclear Power:

High-temperature flue gas filtration.

Filtration of reactor coolant.

Hydraulic Systems:

High-end return-line or pressure-line filters in critical systems.

Filtration Rating: Determine the required micron size based on the component to be protected or the final product specification.

Material Compatibility: The alloy must be compatible with the fluid's chemistry (pH, oxidation potential) and temperature.

Operating Conditions: Maximum operating pressure, allowable pressure drop, temperature, and flow rate.

Physical Configuration: Cartridge dimensions (length, OD, ID), connection type (e.g., double open ended, 222/226 bayonet, threaded), and the need for a center core or end caps.

Brand & Quality: Select a reputable manufacturer to ensure consistent performance and reliability.