This is a comprehensive overview of specialized stainless steel melt filter cartridges, which are critical precision components used in the production of chemical fibers (e.g., polyester, nylon, polypropylene). Their performance directly impacts the quality, efficiency, and cost of the final synthetic fiber.

In chemical fiber production (e.g., spinning), polymer chips are heated into a molten state (melt). This melt can contain impurities like:

Gel particles: Oxidized or cross-linked polymer.

Carbonized particles: Degraded polymer from overheating.

Catalyst residues: Metal particles from the polymerization process.

Mechanical impurities: Dirt or wear particles from equipment.

If not removed, these contaminants will:

Clog spinnerets: Cause filament breakage and production downtime.

Create defects: Form "shot" or lumps in the fiber, degrading yarn and fabric quality.

Reduce product strength: Act as weak points in the filament.

The primary function of the melt filter cartridge is to efficiently capture these solid impurities before the melt reaches the spinneret, ensuring a continuous, stable spinning process and high-quality fiber output.

High Filtration Efficiency: Offers a wide range of filtration ratings, typically from 1μm to 100μm, meeting the stringent requirements of various fiber types (e.g., micro-denier fibers need higher precision).

High Dirt Holding Capacity: The 3D random fiber matrix provides a large surface area and tortuous path for depth filtration, significantly extending service life and reducing change-out frequency.

High Strength & Pressure Resistance: The high-temperature sintering process creates metallurgical bonds between fibers, resulting in a robust structure that can withstand high system pressures (up to 30 MPa or more) and large pressure differentials without collapsing or bursting.

Excellent Corrosion Resistance: Manufactured from high-grade stainless steels like 316L or 310S, providing resistance to corrosion from high-temperature polymer melts.

High-Temperature Resistance: Can operate continuously at temperatures ranging from 280°C to 350°C (536°F to 662°F), with short-term peak resistance even higher.

Excellent Cleanability & Reusability: After clogging, they can be effectively regenerated through high-temperature incineration (burn-off), ultrasonic cleaning, and acid/alkali washing to remove polymer residue. This reusability drastically reduces operating costs.

High Flow Rate & Low Flow Resistance: High porosity (often >80%) ensures efficient melt passage with relatively low pressure drop, saving energy.

| Feature | Sintered Stainless Fiber Cartridge (Modern Standard) | Multilayer Wire Mesh Cartridge (Traditional) |

|---|---|---|

| Filtration Mechanism | Depth Filtration (3D network) | Surface Filtration (relies on mesh size) |

| Filtration Precision | High and consistent, wide range | Lower, requires many layers for high precision |

| Dirt Holding Capacity | Very High | Low, prone to surface blinding |

| Strength/Pressure Resistance | Very High (monolithic structure) | Layers can shift, vulnerable at high pressure |

| Reusability | Excellent, can be cleaned multiple times | Poor, often damaged during cleaning, usually disposable |

| Cost | Higher initial cost, lower long-term cost | Lower initial cost, higher long-term cost (frequent replacement) |

Polyester (PET): Filament yarn, staple fiber, industrial yarn, and bottle chip spinning.

Nylon (PA6 / PA66): High-speed spinning (HOY, POY) and industrial yarn.

Polypropylene (PP): Non-woven fabric and filament production.

Meltblown Nonwovens: Production of high-efficiency filtration media.

Other Polymers: Spinning of materials like PLA (Polylactic Acid).

Micron Rating Selection: Choose the precision (e.g., 10-20μm for micro-denier, 25-40μm for常规 (chángguī -常规) fiber) based on product requirements and raw material quality.

Material Selection: 316L is the most common and cost-effective choice. For more corrosive environments (e.g., some nylon processes), consider higher-grade alloys like Hastelloy.

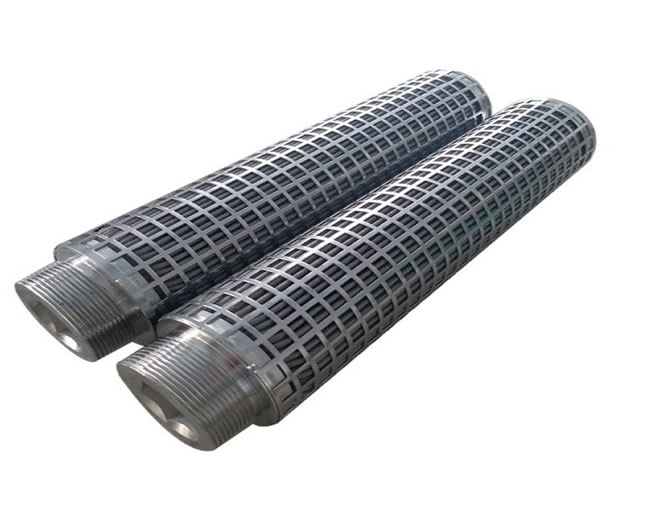

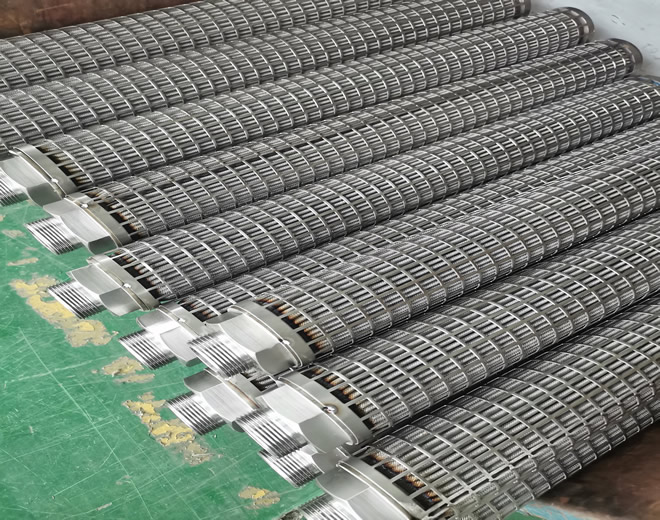

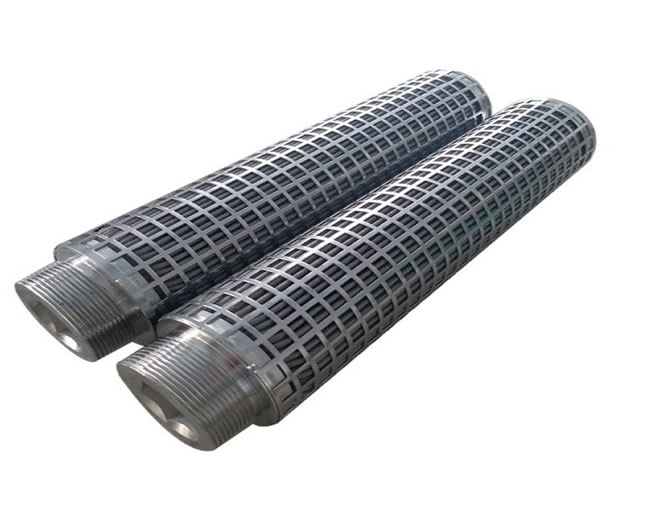

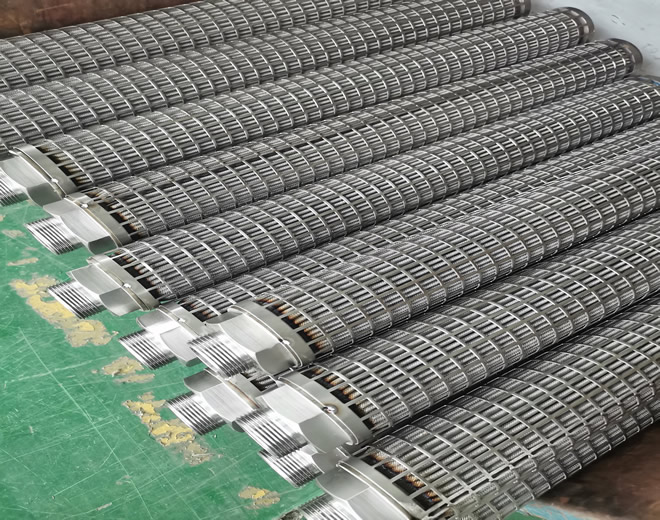

Construction Type: Main types are Flat Discs, Pleated Cartridges (larger surface area, slower pressure rise), and Sleeve Filters. Pleated designs are modern mainstream for their longer life.

Installation and Use: Must be installed correctly in the housing to prevent melt bypass. Monitor inlet pressure and differential pressure (ΔP); change or clean cartridges when ΔP reaches the maximum recommended limit.

Cleaning and Regeneration: A standardized cleaning protocol is key to cost savings. Standard steps: Disassembly -> High-Temperature Burn-off -> Acid/Alkali Soak -> Ultrasonic Cleaning -> Rinsing -> Drying -> Inspection.

Stainless steel melt filter cartridges are indispensable, high-tech components in modern chemical fiber manufacturing. They have largely replaced traditional wire mesh due to their superior filtration precision, long service life, and reusability. They ensure product quality, enhance production efficiency, and reduce operational costs. When selecting a cartridge, it is crucial to consult with a specialized supplier to choose the optimal product for your specific polymer and process conditions.