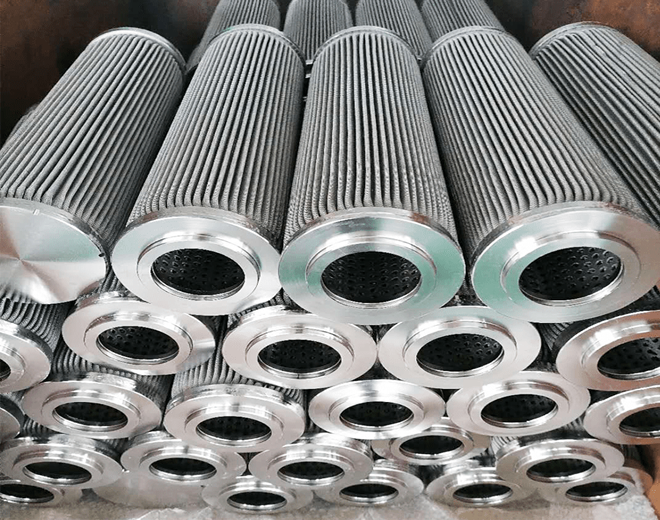

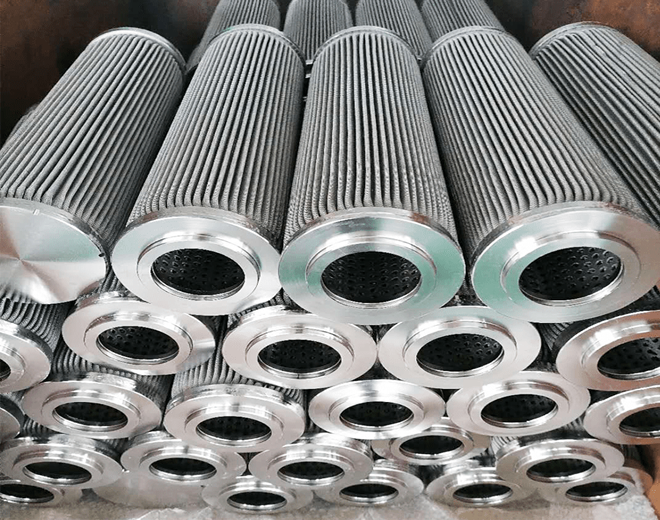

Stainless steel sintered fiber felt filter cartridges are critical components in modern pharmaceutical manufacturing, particularly in sterile dosage form and biopharmaceutical production. Their superior physicochemical properties, exceptional reliability, and compliance with stringent regulatory standards make them indispensable for key processes.

Excellent Filtration Precision & Efficiency: Constructed by stacking and sintering multiple layers of stainless steel fibers with varying diameters, they create a gradient pore structure. They offer a wide range of filtration ratings (from200μm down to 0.5μm), efficiently removing particulate matter, microorganisms, and even bacteriophages.

High Mechanical Strength & Pressure Resistance: The all-metal construction allows them to withstand high inlet pressures and pressure differentials without rupturing or deforming, ensuring process continuity and safety. They are resistant to pressure shocks from frequent backwashing and sterilization.

Outstanding Thermal & Corrosion Resistance: They can endure high temperatures (typically above 500°C / 932°F), making them perfectly suited for Sterilize-in-Place (SIP) procedures—a cornerstone of aseptic processing. They also exhibit excellent resistance to acids, alkalis, and organic solvents.

Non-Shedding & Inert: The monolithic, binder-free inert metal structure guarantees no release of fibers or particles into the process stream. This eliminates the risk of downstream contamination and ensures product purity.

Reusability & Long Service Life: They can be regenerated almost completely via methods like back-pulsing, ultrasonic cleaning, or high-temperature baking (burn-off), resulting in a very long lifespan and a lower total cost of ownership.

Easy Cleaning & Sterilization (CIP/SIP): The smooth surface and uniform structure prevent material entrapment and facilitate easy Clean-in-Place (CIP). Their ability to withstand repeated steam sterilization is a primary reason for their selection in sterile applications.

Integrity Testability: Compliant with GMP/FDA requirements, they can be integrity tested using methods like Bubble Point, Diffusion Flow, or Pressure Hold tests. This provides documented evidence of performance and retention efficiency, which is crucial for product safety and regulatory compliance.

These properties translate into critical roles across various pharmaceutical manufacturing stages:

Sterilizing Grade Filtration in Aseptic Processing:

Application Point: Terminal sterilization of final drug products (e.g., injectables, ophthalmic solutions) immediately before filling.

Requirement: Must use steam-sterilizable and integrity-testable 0.22 µm (or 0.1 µm) absolute rated filters to ensure a Sterility Assurance Level (SAL) of ≤ 10⁻⁶. Sintered steel cartridges are a premium choice for this critical application.

Process Gas Filtration:

Removing oil, water, particles, and microorganisms from compressed air, nitrogen, oxygen, and other process gases.

Used for inlet and exhaust air filtration on fermenters and bioreactors to prevent bacterial and phage contamination.

Used in pneumatic systems for material transfer and packaging lines to ensure the cleanliness of all product-contact gases.

Solvent and Raw Material Filtration:

In Active Pharmaceutical Ingredient (API) manufacturing, they filter aggressive liquids like organic solvents, strong acids, and alkalis to remove particulate impurities and protect downstream equipment (e.g., pumps, chromatography columns).

Clarification of Fermentation Broth and Cell Harvest:

In biopharmaceuticals, they are used to capture cells, cell debris, and insoluble proteins from harvest streams. They act as a robust pre-filtration step before depth or membrane filters, reducing the burden on downstream purification systems.

High-Temperature Process Fluid Filtration:

Ideal for applications requiring hot filtration, such as in Water for Injection (WFI) distribution loops or other high-temperature process streams, where their thermal stability outperforms polymer membrane filters.

Recovery and Recycling Systems:

Used for the filtration and recovery of precious catalysts (e.g., Pd/C).

Employed in CIP systems to filter and recycle cleaning agents, extending their usable life.

Despite their advantages, careful consideration is necessary for pharmaceutical applications:

Surface Finish: Surfaces in contact with the product fluid are typically electropolished (EP) to achieve a very low surface roughness (Ra value). This minimizes adsorption, facilitates cleaning, and enhances sterilization efficacy.

Material Certification: Material must be certified to meet relevant standards (e.g., 316L stainless steel compliant with ASME BPE, FDA requirements) to ensure corrosion resistance and biocompatibility.

Integrity Testing: Integrity testing is mandatory before and after every sterilization and use cycle. It is the core objective evidence proving the filter's sterility assurance performance and must be performed per strict Standard Operating Procedures (SOPs).

Cleaning and Revalidation: Even though reusable, the effectiveness of the cleaning process must be validated after each cycle (e.g., testing rinse water quality, performing integrity tests) to ensure performance restoration and absence of cross-contamination.

Initial Pressure Drop: Compared to polymer membrane filters of similar rating, sintered metal cartridges may have a higher initial pressure drop, which should be considered during system design.