In many industrial sectors such as chemical processing, metallurgy, and energy, production processes often involve extreme temperatures. Under these harsh conditions, conventional filter media can quickly fail, melt, or decompose, jeopardizing continuous and stable equipment operation. The high-temperature sintered felt filter cartridge is an advanced filtration element designed specifically to meet this challenge. It serves as a reliable guardian for high-temperature process fluids, renowned for its exceptional heat resistance, superior filtration performance, and long service life.

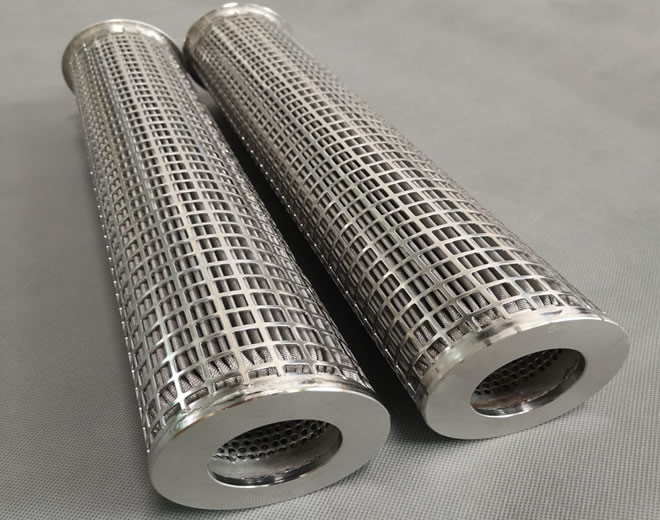

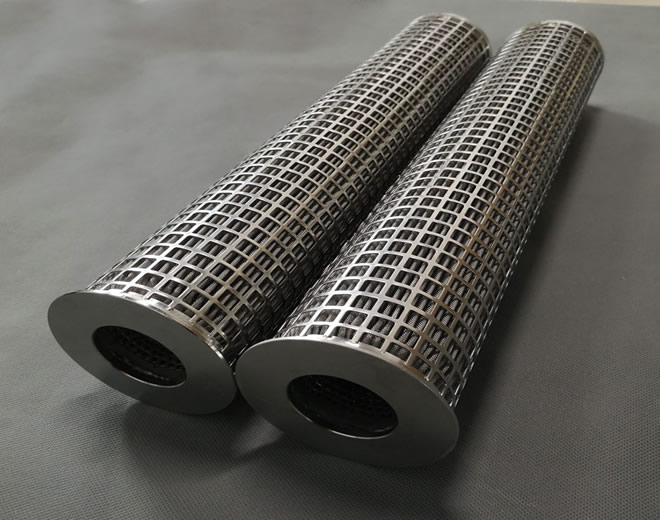

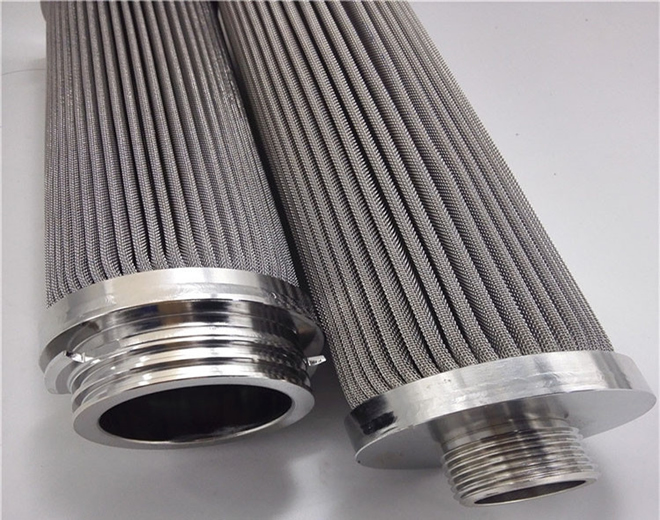

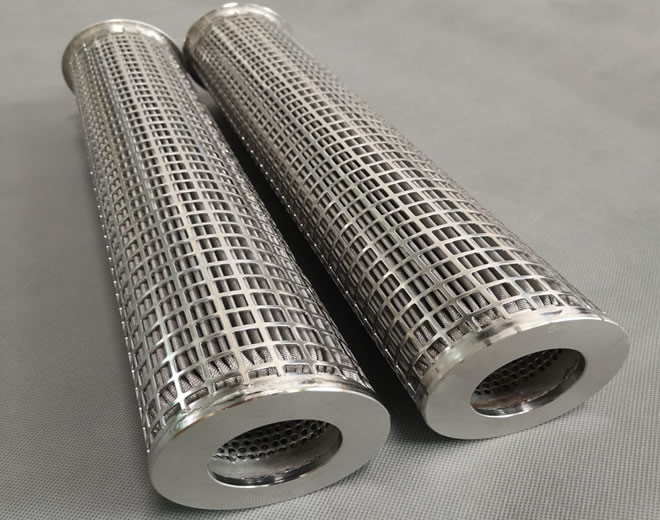

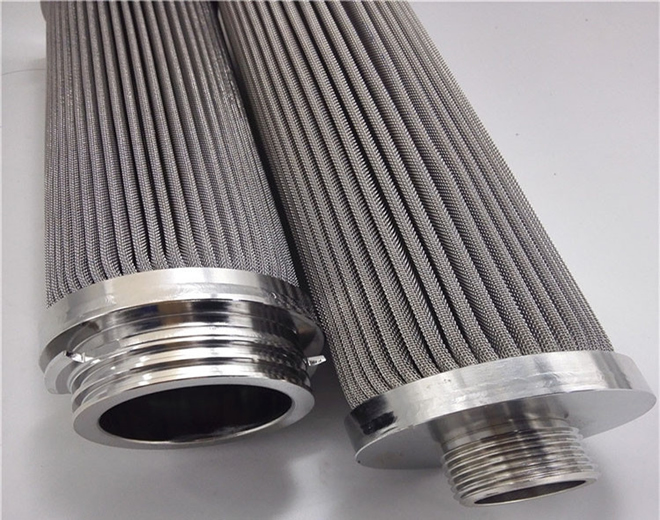

A high-temperature sintered felt filter cartridge is a three-dimensional, porous, depth-type filter medium made from very fine metal fibers (such as FeCrAl alloy, stainless steel, nickel-based alloy, etc.). These fibers are layered and then sintered at high temperatures in a controlled atmosphere. Unlike sintered wire mesh, sintered felt consists of a random labyrinth of intertwined fibers, creating a structure with high porosity, large dirt-holding capacity, and depth filtration capabilities.

Its high-temperature resistance stems from two key factors:

Inherent Material Properties: The selected metal or alloy fibers have very high melting points (typically exceeding 1300°C) and excellent strength at elevated temperatures.

Sintering Process: The high-temperature sintering creates firm metallurgical bonds at the fiber intersections, ensuring the structural integrity of the cartridge remains stable over long periods under heat, preventing collapse or powdering.

Exceptional High-Temperature Resistance

This is its core advantage. Depending on the material, it can operate continuously in environments ranging from 300°C to 600°C, and withstand even higher short-term thermal shock (e.g., FeCrAl felt can withstand up to 1000°C). This allows direct application in hot gases, molten metal, and high-temperature catalyst recovery.

High Dirt-Holding Capacity and Long Life

The 3D fibrous network provides a vast surface area and complex pores, enabling deep capture and retention of large amounts of contaminants. Its dirt-holding capacity far exceeds that of sintered wire mesh, significantly extending service intervals.

Excellent Filtration Rating

It offers a wide filtration rating range, typically from 1μm to 100μm. Pore size can be precisely controlled by adjusting fiber diameter and felting processes to meet specific accuracy requirements.

Good Permeability and Low Pressure Drop

High porosity (usually 70%-90%) ensures fluid flows smoothly through the cartridge, resulting in a low initial pressure drop and contributing to reduced system energy consumption.

Excellent Thermal Shock Resistance and Mechanical Strength

It can withstand rapid temperature changes without cracking, maintaining good structural stability. It also possesses certain flexibility and mechanical strength to endure vibration and pressure fluctuations.

Cleanability and Regenerability

Similar to sintered mesh, it can be regenerated via high-pressure back-pulsing, ultrasonic cleaning, or high-temperature burn-off to remove accumulated dust or coke from the surface and depth, allowing for multiple reuses and lowering the total cost of ownership.

High-temperature sintered felt cartridges are the ideal choice for the following demanding applications:

Chemical Industry: Filtration of high-temperature polymer melts (e.g., polyester, nylon); catalyst recovery and separation in high-temperature reactors.

Metallurgy Industry: Filtration and purification of molten non-ferrous metals like aluminum, zinc, and copper to remove oxides and non-metallic inclusions, improving casting quality.

Energy & Environmental Protection: Hot gas and flue gas purification, such as high-temperature dust removal in coal chemical and waste-to-energy systems, protecting downstream turbines or heat exchangers.

Glass Manufacturing: Filtering fuel gas for glass melting furnaces to ensure stable and efficient burner operation.

Powder Metallurgy: Inert gas filtration in high-temperature sintering furnaces.

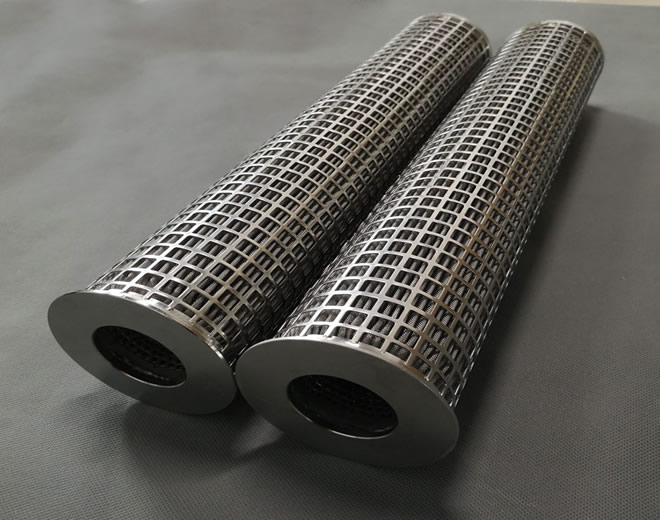

| Feature | High-Temperature Sintered Felt Cartridge | High-Temperature Sintered Wire Mesh Cartridge |

|---|---|---|

| Filtration Mechanism | Depth Filtration: Contaminants are trapped within the bulk of the material. | Surface Filtration: Contaminants are primarily retained on the surface. |

| Dirt-Holding Capacity | Very High, leading to longer service life. | Relatively lower. |

| Filtration Rating | Wide range, but pore size uniformity is generally lower than sintered mesh. | Precisely controlled rating, very uniform pores, high reliability. |

| Mechanical Strength | Good, but more flexible. | Extremely High, rigid structure, better impact resistance. |

| Back-Pulse Cleaning | Deeply trapped contaminants can be harder to remove completely; regeneration efficiency may decrease over cycles. | Surface retention allows easy and highly effective cleaning. |

| Typical Application | Ideal for high-temperature depth filtration where contaminant load is high and high dirt-holding capacity is required. | Suitable for high-temperature surface filtration where precise rating, high strength, and frequent cleaning are critical. |

Maximum Operating Temperature: Select the appropriate material (e.g., 304/316L SS, FeCrAl, Hastelloy) based on the actual process temperature.

Filtration Rating & Dirt-Holding Need: For high contaminant loads with fine particles and long cycle requirements, sintered felt is preferred. For absolute precision and easy cleaning, choose sintered mesh.

Chemical Environment: Consider the corrosiveness of the process media at high temperatures when selecting the alloy.

Pressure Drop & Flow Rate: Select the cartridge size and porosity based on system flow requirements and allowable pressure drop.