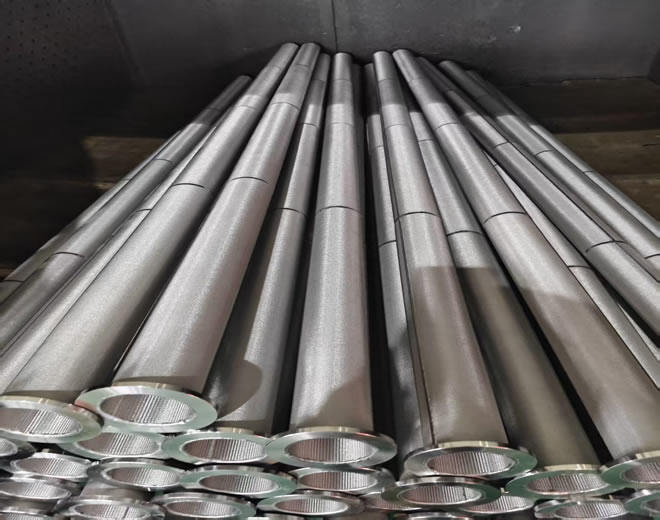

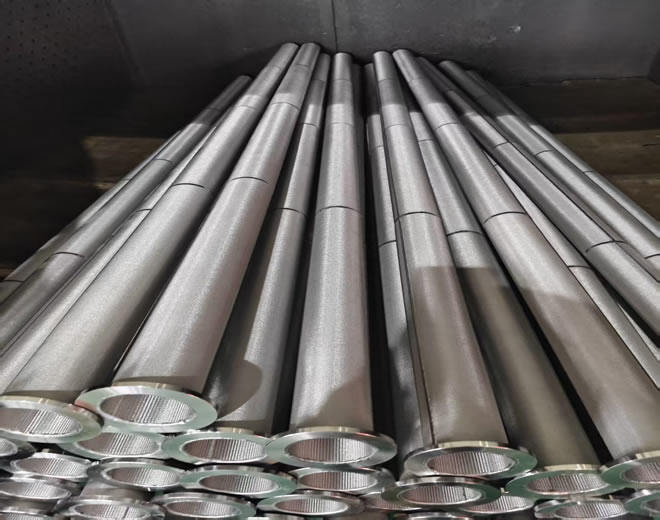

Stainless Steel Sectionally Sintered Mesh Filter Cartridge: A Comprehensive Overview

The stainless steel sectionally sintered mesh filter cartridge is a high-end filtration component that utilizes multilayer stainless steel sintered mesh as its core filtering material and is manufactured through a sectional splicing (modular) process. It combines the advantages of sintered mesh with the flexibility of modular design, specifically addressing the challenges faced by traditional single-piece cartridges in ultra-long length, ultra-high strength, or complex application environments.

1. Core Material: Multilayer Stainless Steel Sintered Mesh

This is not ordinary wire mesh. It is a porous functional material created by layering multiple stainless steel wire meshes with different pore sizes and functions and sintering them under high temperature in a vacuum or protective atmosphere. Its typical structure includes:

Filter Layer (Control Layer): The core layer that determines the filtration rating, typically made of very fine wire mesh.

Protective Layers: Located on both sides of the filter layer, made of thicker wire for robust structure, protecting the delicate filter layer from mechanical impact and direct abrasion.

Dispersion/Support Layers: Further reinforce the structure and help distribute the fluid evenly.

2. Key Process: Sectional (Modular) Design

This is the core feature distinguishing it from traditional one-piece sintered mesh cartridges.

Process: Large sheets of sintered mesh are first pleated into standard short cartridge modules. Multiple such modules are then connected in series onto a central core/skeleton using precision welding techniques like laser welding or plasma welding to form one long cartridge.

Appearance: The finished product may show segmented junctions along its length, but the internal flow path and filtration performance are continuous.

Exceptional Mechanical Strength: The multilayer sintered structure provides extremely high pressure resistance and impact strength, capable of withstanding very high differential pressures (up to tens of MPa) without deformation or damage.

Absolute Filtration Rating: Provides an absolute filtration rating with a particle removal efficiency close to 100%. It offers a wide filtration range, typically from 1µm to 100µm.

Superior Anti-Clogging Capability: Due to its surface filtration mechanism and uniform pore structure, contaminants primarily accumulate on the surface rather than inside the depth, making cleaning easier and offering higher dirt holding capacity.

Advantages of Modular Design:

Solves Thermal Deformation: Ultra-long cartridges are prone to warping due to thermal stress during sintering and welding. Sectional manufacturing and splicing effectively control deformation, ensuring product straightness and precision.

Easier Maintenance: If one section of the cartridge is damaged under extreme conditions, in theory, only the damaged module needs replacement, reducing maintenance costs (though full cartridge replacement is common practice).

Production Flexibility: Enables the manufacture of ultra-long cartridges exceeding 2 meters or more to meet the needs of special equipment.

Excellent Chemical and Thermal Stability: Made entirely from materials like 316L stainless steel, it offers strong corrosion resistance and high-temperature tolerance (up to 500°C and above), suitable for extreme operating conditions.

Excellent Cleanability: Supports various efficient cleaning methods such as online high-pressure backwashing, ultrasonic cleaning, and chemical soaking. It can be reused multiple times, offering a very long service life.

It operates primarily on the Surface Filtration mechanism:

Fluid passes from the outside of the cartridge through the multilayer sintered mesh towards the inside.

Particles larger than the pore size of the mesh are directly intercepted on the cartridge's outer surface.

As filtration progresses, a uniform filter cake layer forms on the surface. This cake layer itself can participate in fine filtration.

When the pressure drop reaches a set value, the filter cake layer is thoroughly removed via reverse flow (backwashing) or chemical cleaning, restoring filtration performance.

This high-performance cartridge is designed for the most demanding industrial applications:

Petrochemical and Refining:

High-Pressure Polymer Melt Filtration (e.g., tertiary filtration for PET, PE, PP melts).

Catalyst recovery and capture.

Feedstock filtration for high-pressure hydrogenation units.

Chemical Fiber Industry: Precision filtration of spinning melt, serving as a critical protective device before the spinneret.

High-Temperature Gas Purification: Removal of dust from high-temperature coal gas and process gases in chemical industries.

Nuclear Power Industry: Filtration of high-temperature, high-radioactivity media in nuclear fuel processing.

Coal Water Slurry and Harsh Duties: Filtration of high-pressure, highly abrasive slurries.

Selection Considerations:

Filtration Rating: Determined based on upstream contaminants and downstream protection requirements.

Material Grade: 316L is typically the first choice; for more corrosive environments, Hastelloy, Monel, etc., can be selected.

Structural Dimensions: Determine cartridge outer diameter, length, assembly method (e.g., with/without central core), and connection type.

Operating Parameters: Must specify operating pressure, differential pressure, temperature, flow rate, and fluid chemical properties.

Use and Maintenance:

Installation: Handle with care to avoid damaging the end cap sealing surfaces. Ensure vertical and proper installation.

Monitoring: Real-time monitoring of the inlet-outlet differential pressure is the most important indicator for assessing cartridge status.

Cleaning:

Online Backwashing: The most common and efficient method, using clean compressed air or liquid for reverse flushing.

Offline Cleaning: Can employ ultrasonic cleaning, specialized chemical soaking, or low-pressure water jet cleaning.

Replacement: Replacement is necessary when the initial pressure drop remains high even after repeated cleaning, or if the cartridge sustains irreparable physical damage (e.g., mesh rupture, weld crack).

The stainless steel sectionally sintered mesh filter cartridge is a "premium product" in metal filtration technology. Through its multilayer sintering and modular splicing techniques, it delivers long-term, stable, and reliable performance under extreme conditions such as ultra-high pressure, high temperature, and strong corrosion. Although its initial cost is high, its exceptionally long service life, superior filtration performance, and regenerative capability often result in a favorable total cost of ownership over its lifecycle. It is a strategic choice for solving high-end process filtration challenges.