Methanol, a vital chemical feedstock, solvent, and clean energy source (e.g., methanol fuel), requires a high level of purity to ensure the efficiency of downstream processes, the quality of final products, and the overall safety and stability of operational systems. Whether used as fuel for fuel cells or as a raw material for chemical synthesis, trace solid particles, water, oils, and metal ions in methanol can lead to:

Catalyst Poisoning and Deactivation: In chemical synthesis, impurities can cover the active sites of catalysts, causing a sharp drop in reaction efficiency and significant economic losses.

Equipment Wear and Clogging: Abrasive particles can wear down precision components such as pumps, nozzles, and metering valves, and clog pipelines and reactors.

Product Contamination: Compromising the purity and grade of final chemicals or fuels.

Safety Risks: In fuel cells, impurities can damage expensive membrane electrode assemblies (MEAs), leading to performance degradation and failure.

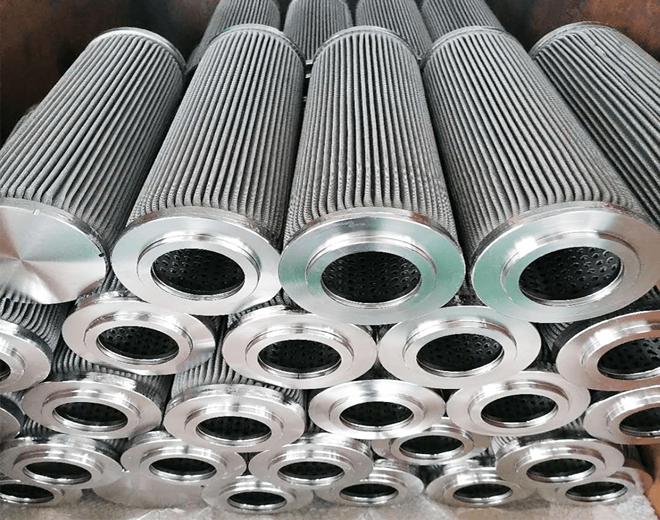

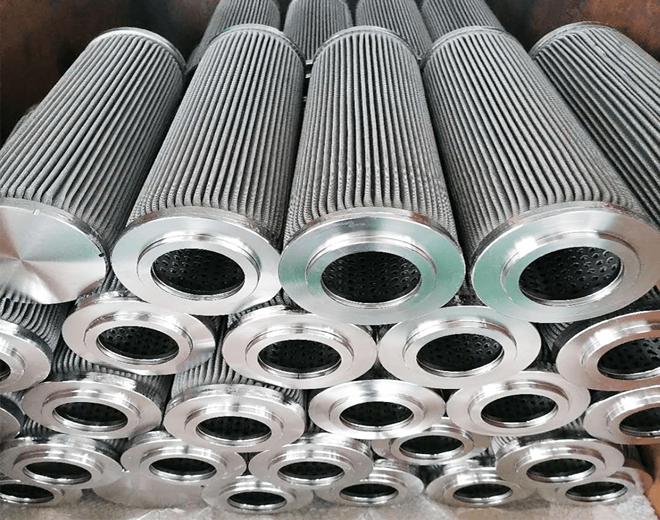

Therefore, employing a high-performance stainless steel methanol filter cartridge is an indispensable step for achieving efficient and safe methanol applications.

Stainless steel methanol filter cartridges are specifically designed to meet the chemical properties of methanol (volatile, permeable, with certain solvency) and the demanding requirements of industrial applications. They offer the following outstanding advantages:

Superior Corrosion Resistance:

Material: Typically constructed from 316L Stainless Steel. Its low carbon content and added molybdenum provide exceptional resistance to methanol and potential trace corrosive media like chlorides, preventing cartridge corrosion and avoiding secondary contamination.

High Filtration Efficiency and Precision:

Available in a wide range of filtration ratings, from 0.1μm to 100μm, to meet various requirements.

Absolute-rated cartridges reliably retain all particles larger than the specified size, providing consistent and dependable protection for downstream processes.

No Media Migration, Zero Contamination:

The filter medium, made from sintered stainless steel fiber felt or powder, is a monolithic, three-dimensional network structure formed through high-temperature sintering without any binders. This construction ensures that fibers or particles will not shed under pressure shock or fluid冲刷, guaranteeing ultra-high purity of the filtered methanol.

Excellent Strength and Stability:

Capable of withstanding high system operating pressure differentials (often up to several MPa). Their high mechanical strength prevents deformation and damage.

Resistant to high temperatures, making them suitable for in-place steam sterilization (SIP) and high-temperature processes, meeting requirements for bio-chemical or food-grade applications.

Cleanable and Long Service Life (Cost-Effectiveness):

When the pressure drop increases due to clogging, the cartridges can be regenerated through methods like ultrasonic cleaning, chemical solvent soaking, or backwashing. This restores most of the filtration performance, allows for multiple reuses, and significantly reduces long-term operating costs.

Construction:

Filter Layer: Made of stainless steel sintered felt, precision-pleated to provide maximum filtration surface area within a compact volume.

Core: A stainless steel support core prevents the filter media from collapsing under high pressure.

End Caps and Seals: Stainless steel end caps are integrally welded to the media and core via TIG welding, ensuring a leak-proof construction. Sealing is typically achieved with O-rings (compatible with methanol, e.g., FKM/FFKM).

Working Principle:

The methanol fluid to be filtered flows from the outside of the cartridge to the inside, driven by pressure. As it passes through the dense, porous 3D network of the filter medium, solid particle impurities are mechanically sieved, adsorbed, and trapped on the surface and within the depth of the media. Clean methanol passes through the medium and exits from the central core into the downstream system.

These filter cartridges are widely used in all scenarios demanding high methanol purity:

Methanol Fuel Cells: Serve as the final filter in the fuel supply system to protect the core fuel cell stack.

Chemical Synthesis: Protect valuable catalysts and reactors in processes like Methanol-to-Olefins (MTO), methanol reforming for hydrogen, and formaldehyde production.

Fine Chemicals and Pharmaceuticals: Used for final filtration of high-purity methanol solvents, ensuring the quality of active pharmaceutical ingredients (APIs) and intermediates.

Methanol Gasoline/Fuel: Filter impurities at blending and dispensing stations to protect engines and storage/transport equipment.

Electronics Industry: Used for filtering electronic-grade methanol, which serves as a cleaning agent in semiconductor and display panel manufacturing.

Selecting the Right Rating: Choose based on the protection requirements of downstream equipment and the initial contamination level of the methanol. For instance, fuel cells typically require ratings of 0.5μm or higher to protect the MEA.

Material Confirmation: 316L Stainless Steel is the preferred choice. For electronic-grade applications with strict metal ion requirements, higher-grade materials can be considered.

Seal Compatibility: Always ensure that the O-ring material (e.g., Viton™, EPDM, FFKM) is fully compatible with methanol to prevent swelling, degradation, and leaks.

Installation and Operation:

Flush the cartridge and filter housing with clean methanol before installation.

Pressurize the system gradually during start-up to avoid pressure shock.

Replacement and Cleaning Schedule:

Replace or clean the cartridge when the differential pressure across the filter reaches the manufacturer's recommended limit (typically 0.3-0.5 MPa/ ~50 PSI), indicating it is loaded with contaminants.

After cleaning, perform an integrity test (e.g., bubble point test) to verify that the cartridge's performance has been restored and it is undamaged.

The stainless steel methanol filter cartridge is more than a simple mechanical filter; it is a strategic component in modern methanol-based industries for safeguarding product quality, production efficiency, and system safety. Its exceptional chemical stability, precise filtration performance, and cost-effective long service life make it an indispensable guardian in numerous high-end fields, from energy and chemicals to electronics and pharmaceuticals. Selecting the appropriate cartridge and maintaining it correctly is fundamental to achieving optimal performance in any methanol system.