Application of Stainless Steel Sintered Felt Filter Elements in Fuel Exhaust Gas

As environmental regulations become increasingly stringent, controlling pollutant emissions from fuel exhaust gases has become a critical issue in the global transportation and industrial sectors. Harmful substances in fuel exhaust gases, such as carbon monoxide, nitrogen oxides (NOx), particulate matter (PM), and others, pose significant risks to both the environment and human health. Therefore, the use of efficient filters for exhaust gas purification has become an inevitable choice for industrial development. Stainless steel sintered felt filter elements, known for their high efficiency, high temperature resistance, and strong corrosion resistance, are widely used in exhaust gas treatment systems for fuel emissions.

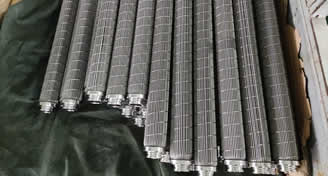

1. What is a Stainless Steel Sintered Felt Filter Element?

A stainless steel sintered felt filter element is made from multiple layers of stainless steel fiber mesh that are processed through a sintering process. The resulting material has excellent filtration performance and mechanical strength. Sintered felt is a material formed by bonding stainless steel wires at high temperatures, resulting in a porous, net-like structure that improves filtration accuracy and stability.

2. Advantages of Stainless Steel Sintered Felt Filter Elements

-

High Temperature Resistance: Stainless steel sintered felt filter elements can withstand extremely high temperatures for extended periods. This characteristic is especially important in fuel exhaust treatment, such as in diesel engines, where exhaust gases can reach high temperatures. The ability to endure these conditions ensures that the filter elements remain effective over time.

-

Corrosion Resistance: Fuel exhaust gases often contain acidic gases and other chemical substances, such as sulfur compounds and nitrogen oxides, which can cause corrosion. The inherent corrosion resistance of stainless steel ensures that sintered felt filter elements can withstand these aggressive chemicals, providing long-term durability and stable performance in harsh environments.

-

Efficient Filtration Performance: The filter elements have a uniformly distributed pore structure, which enables them to efficiently remove fine particles, including submicron-sized particles. This high filtration efficiency is crucial for removing particulate matter, smoke, and other solid pollutants from fuel exhaust gases, thus reducing environmental impact.

-

Cleanable and Reusable: Unlike other filter materials, stainless steel sintered felt filter elements are easy to clean. Thanks to their metal structure, they can be cleaned using methods like backwashing or ultrasonic cleaning, which removes accumulated contaminants and restores the filter’s original performance. This feature allows the filter to have a longer service life and reduces replacement costs.

-

High Mechanical Strength: The sintered felt filter elements possess high mechanical strength, allowing them to withstand high pressures and high flow rates. In fuel exhaust treatment systems, filters often face significant gas flow pressures, and the strength of stainless steel sintered felt ensures that the filter elements maintain their integrity and effectiveness over time.

3. Application of Stainless Steel Sintered Felt Filter Elements in Fuel Exhaust Gas

-

Diesel Engine Exhaust Treatment

Diesel engine exhaust gases are known to contain high levels of nitrogen oxides (NOx) and particulate matter (PM), especially fine particles that contribute to air pollution. Stainless steel sintered felt filter elements can efficiently remove these particles, reducing harmful emissions and helping meet environmental standards. -

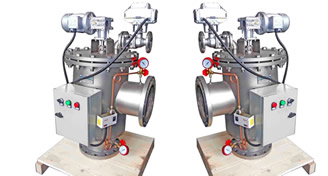

Key Component in Exhaust Gas Purification Systems

In fuel exhaust gas treatment systems, filter elements are crucial for ensuring the overall efficiency of the system. The filtration performance directly impacts the emission levels. By using stainless steel sintered felt filter elements, the purification efficiency of the entire system can be improved, thereby reducing emissions and meeting stringent environmental regulations. -

Automobile Exhaust Aftertreatment Technology

With increasingly strict exhaust emission standards, the automotive industry has adopted stainless steel sintered felt filter elements as part of their exhaust aftertreatment systems. These filters help effectively reduce particulate matter in vehicle exhaust, making it possible for automobiles to comply with national and international emission standards.

4. Future Development Trends of Stainless Steel Sintered Felt Filter Elements

As environmental regulations continue to tighten, the demand for more efficient exhaust gas purification systems will increase. Stainless steel sintered felt filter elements, with their superior durability and filtration capabilities, will play an even more prominent role in various applications. Specifically, in heavy-duty diesel engines, industrial exhaust gas treatment, and other high-pollution emission sources, stainless steel sintered felt filters will continue to be an essential part of the solution.

Moreover, as new materials and advanced manufacturing technologies evolve, the performance of stainless steel sintered felt filter elements will be further enhanced, such as improvements in pore size optimization, filtration efficiency, and anti-contamination capabilities. These advancements will make stainless steel sintered felt filters even more suitable for future fuel exhaust treatment needs, contributing to the development of a more sustainable environment.

Conclusion

The issue of pollutant emissions in fuel exhaust gases is one of the most significant challenges facing global environmental efforts today. Stainless steel sintered felt filter elements, with their excellent high-temperature resistance, corrosion resistance, efficient filtration, and cleanability, make them an ideal choice for fuel exhaust gas treatment systems. With ongoing technological advancements, their application scope will continue to expand, playing a vital role in improving air quality and promoting sustainable development.