In modern industry, from cleanrooms to complex pneumatic systems, and from chemical reactors to respiratory protection equipment, the purity of gases is paramount. Minute solid particles, moisture, or oil aerosols can lead to equipment failure, product rejection, or even safety incidents. In this "battle for purification," the Stainless Steel Sintered Wire Mesh Filter Element has emerged as an indispensable component, renowned for its exceptional performance.

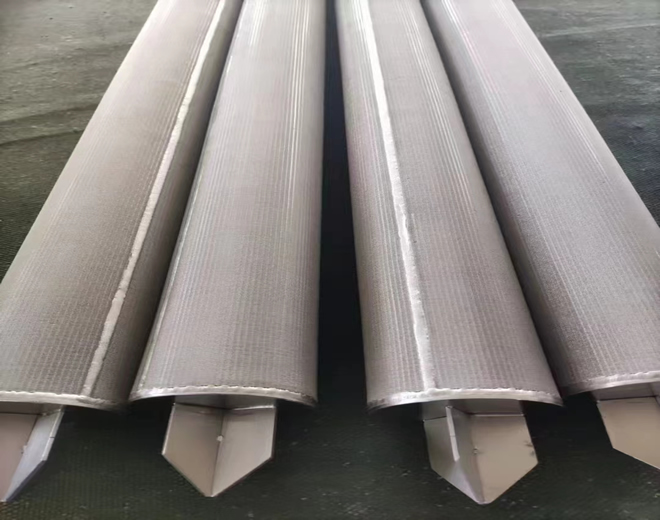

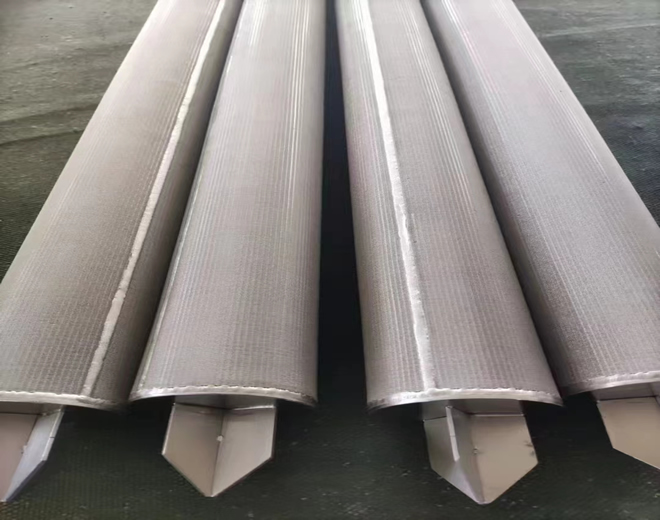

A stainless steel sintered wire mesh filter element is a porous functional material manufactured by layering multiple sheets (typically 2-5) of stainless steel wire mesh with different pore sizes. These layers are then subjected to a specialized process of lamination, pressing, and vacuum sintering. This process is not merely a physical stacking; under high temperature and pressure, the contact points between adjacent mesh layers diffuse and fuse, forming a monolithic, robust three-dimensional network structure with uniform porosity and high strength.

Typical Multi-Layer Structure:

Protective Layer: The outermost layer, usually made of thicker wires and larger pores. Its primary role is to trap large particles, preventing premature clogging of the core filtration layer and extending service life.

Filtration Layer: The middle one or several layers, made of precise wire diameters and pore sizes. This is the core layer that achieves high-precision filtration, responsible for capturing target-sized fine particles.

Support Layer: The innermost layer, made of a high-strength coarse mesh. It provides rigid mechanical support for the entire element, ensuring it does not deform or collapse under high differential pressure.

Filtration Mechanisms:

Surface Filtration: Particles larger than the mesh pore size are directly intercepted on the surface of the element.

Depth Filtration: Particles smaller than the nominal pore size are adsorbed within the fiber matrix as they navigate the tortuous three-dimensional network of pores, through mechanisms like inertial impaction, direct interception, and diffusion. This allows for higher efficiency purification.

High Strength & Pressure Resistance: The monolithic sintered structure gives it exceptional mechanical strength and toughness. It can withstand high operating pressures (up to several dozen bar) and frequent pulse-jet cleaning without deformation or rupture.

High Precision & High Dirt Holding Capacity: It offers a wide filtration rating range, from 1μm to 100μm, allowing for precise selection based on needs. The 3D network provides a much greater contaminant capacity than flat filter screens, resulting in a longer service life.

Excellent Resistance:

High-Temperature Resistance: Can operate stably in extreme temperatures from -200°C to +650°C, making it suitable for hot gas and hot air filtration.

Corrosion Resistance: Made from high-quality stainless steels like 304, 316, or 316L, it offers good resistance to acids, alkalis, and organic solvents.

Easy Cleaning & Regenerability: This is one of its most significant economic advantages. When clogged contaminants cause a rise in pressure drop, the element can be thoroughly cleaned via ultrasonic cleaning, chemical soaking, or backwashing. Its performance can be largely restored, allowing for multiple reuses, which drastically reduces long-term operating costs.

Good Permeability & Low Flow Resistance: The uniform pore structure ensures smooth fluid passage with a low initial pressure drop, helping to reduce system energy consumption.

Leveraging these characteristics, stainless steel sintered mesh filter elements are widely used in the following gas filtration applications:

Chemical & Petrochemical Industry: Catalyst recovery, purification of process gases (e.g., nitrogen, hydrogen, oxygen), protection of reactor inlet air.

Electronics & Semiconductor Industry: Point-of-use filtration of high-purity gases (e.g., helium, argon), protecting sensitive production equipment and chip products.

Pharmaceutical & Bioprocessing: Sterilizing, de-oiling, and drying compressed air to ensure aseptic processing (e.g., fermenter aeration).

Metallurgy & Power Generation: Filtration of blast furnace gas and gas turbine intake air, protecting turbine blades and downstream equipment.

Environmental Protection & Energy: Dust filtration in waste incineration flue gas, purification and desulfurization of natural gas and biogas.

Industrial Pneumatic Systems: Serving as precision filters to protect pneumatic components like cylinders and solenoid valves from contamination.

Filtration Rating: Higher is not always better. Select based on the particle size you need to remove and your process requirements. An excessively fine rating will shorten service life and increase costs.

Material Selection: Choose the appropriate material (e.g., 316L offers better corrosion resistance than 304) based on the corrosiveness (e.g., chloride content) and temperature of the gas.

Structural Form: Options include standard pleated (for larger surface area), flat disc, and tubular types. The choice depends on the filter housing space and flow rate requirements.

Use and Maintenance:

Ensure proper sealing during installation to prevent gas bypass.

Regularly monitor the pressure differential across the filter element. Clean or replace it when the differential pressure reaches a set value (typically 0.1-0.2 MPa).

After cleaning, ensure the element is thoroughly dried to prevent rusting.