An Ethylene Glycol Sintered Wire Mesh Filter Element is a high-performance, depth-type filter cartridge specifically designed for filtering ethylene glycol, water-glycol solutions, antifreeze, and related fluids.

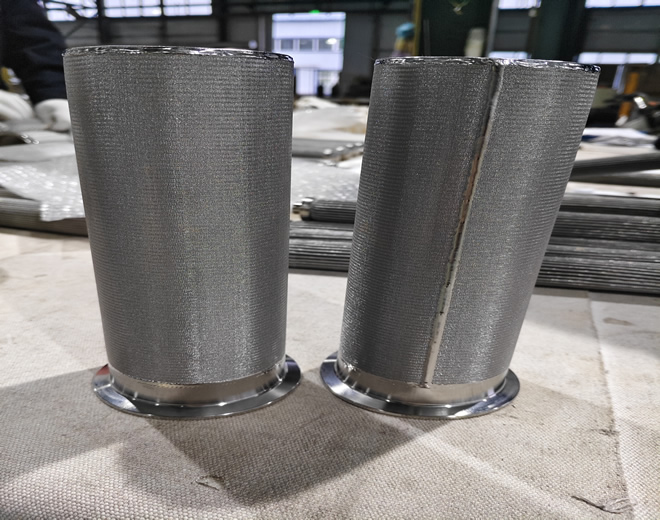

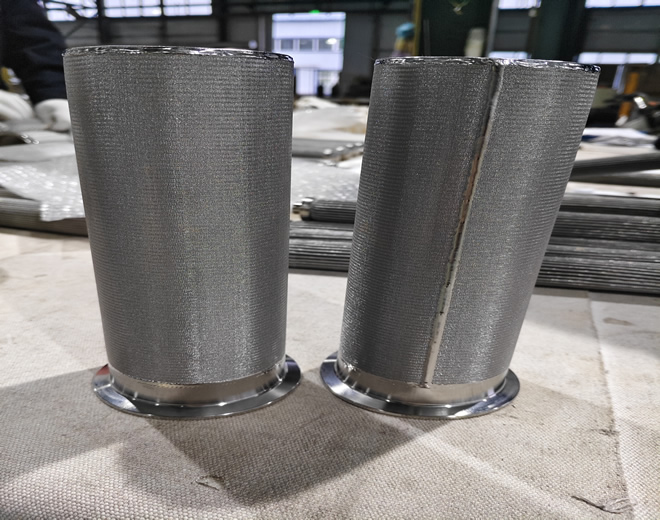

Its core filtering medium is multi-layer stainless steel sintered wire mesh. Through a diffusion bonding/sintering process under high temperature and vacuum, multiple layers of wire mesh with different structures and pore sizes are fused into a single, monolithic, and rigid pore structure. This sintered sheet is then rolled, welded, and assembled into a filter cartridge with end caps and a core.

Excellent Chemical Compatibility:

Made primarily from 316L stainless steel, which offers superior corrosion resistance to ethylene glycol, water-glycol, antifreeze, and a wide range of other chemicals, ensuring long-term durability.

High Strength & Rigidity:

The sintering process creates a filter with high mechanical strength and pressure resistance. It can withstand high differential pressures and frequent pulse backwashing without deformation or damage.

High Filtration Efficiency & Dirt Holding Capacity:

Features a gradient density structure (e.g., protective layer → transition layer → precision layer). Large particles are trapped on the outer surface, while finer particles are captured in the depth of the media. This structure ensures high filtration accuracy and a large contaminant capacity, leading to a long service life.

Standard filtration ratings range from 1μm to 100μm.

Cleanable & Reusable:

This is a major economic advantage. When the pressure drop increases due to clogging, the cartridge can be effectively cleaned via online/offline back-pulsing, ultrasonic cleaning, or solvent soaking, restoring most of its performance and significantly reducing long-term operating costs.

No Media Migration:

Unlike fibrous filter media (e.g., paper, felt), the sintered metal mesh is a monolithic structure that will not shed fibers or particles. This prevents secondary contamination of the downstream fluid, which is critical for protecting sensitive equipment like fuel cells or lithium-ion battery electrolyte systems.

Thermal Shock Resistance:

Capable of withstanding rapid and extreme temperature changes that may occur in ethylene glycol systems without cracking or performance degradation.

Lithium-Ion Battery Manufacturing:

Electrolyte Filtration: A critical process for filtering particulate and moisture contamination from the electrolyte (often dissolved in carbonate solvents) before filling into battery cells. Essential for ensuring battery safety, performance, and lifespan.

Slurry filtration.

Energy Storage & Fuel Cells:

Used to filter water-glycol coolants in thermal management systems, preventing particles from clogging micro-channel cold plates and ensuring system stability.

Automotive & Industrial Systems:

Antifreeze/Coolant Filtration: Filters rust, scale, and seal debris from coolant loops in engines, energy storage containers, etc.

Hydraulic Systems: Filtration of water-glycol fire-resistant hydraulic fluids.

Chemical Processing:

Used as a process filter during the production, storage, and transfer of ethylene glycol to ensure product purity.

Polyester (PET) Fiber Production:

Ethylene Glycol is a key raw material for PET. High-precision filtration is required before the polymerization reaction.

| Parameter | Typical Specification / Description |

|---|---|

| Filter Media | 316L Sintered Stainless Steel Wire Mesh (most common), also available in 304, Hastelloy, etc. |

| Filtration Rating | 1µm, 5µm, 10µm, 25µm, 50µm, 100µm, etc. |

| Configuration | Open (Single) End, Double Open (Candle) End |

| End Cap / Gasket | Flat End, 222/226 O-ring Groove, Flanged, etc. |

| Operating Temperature | Typically up to ≤ 400°C (dependent on seal material) |

| Max. Differential Pressure | Typically 0.5 - 1.0 MPa (dependent on design and rating) |

| Seal Material | Fluorocarbon (FKM/Viton), Silicone (SI), EPDM, Metal Gasket |

Material Compatibility: Confirm that all wetted parts (mesh, core, end caps) and seal materials are fully compatible with your specific ethylene glycol solution (concentration, temperature, other chemicals).

Rating Selection: Choose the appropriate filtration rating based on the protection requirements of downstream equipment and the system's contamination control target. A finer rating is not always better; balance efficiency, flow rate, and dirt capacity.

Installation Direction: Ensure correct flow direction, typically from the outside to the inside of the filter cartridge. Verify that seals are properly installed to prevent bypass.

Pressure Drop Monitoring: Install differential pressure gauges across the filter housing. Replace or clean the element when the delta-P reaches the manufacturer's recommended limit (usually 0.2-0.35 MPa) to prevent element collapse or system flow restriction.

Cleaning Methods:

Back Pulsing: Use clean, dry compressed air or nitrogen from the inside out. Pressure should not be excessive (recommended 0.4-0.5 MPa) to avoid damaging the mesh.

Ultrasonic Cleaning: Most effective method. Use a suitable cleaning agent (e.g., alkaline or neutral solution).

Chemical Cleaning: Soak in a mild acid or alkaline solution for stubborn contaminants, ensuring the cleaning fluid does not corrode the stainless steel.