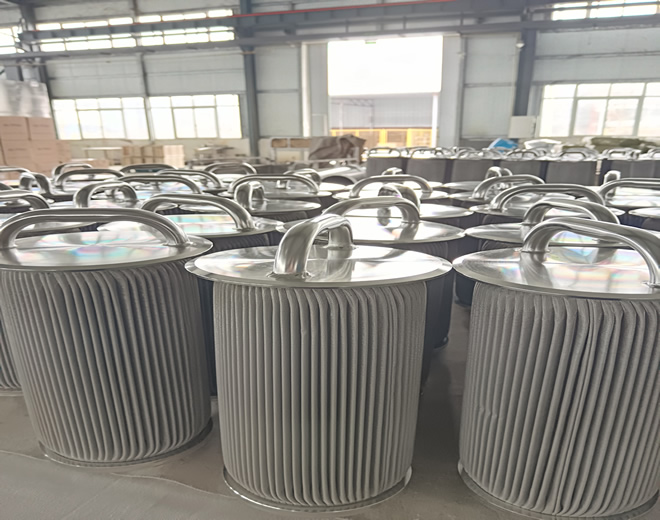

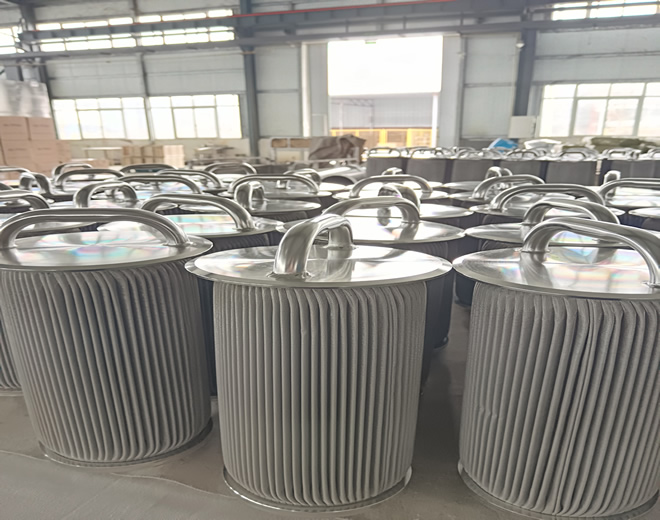

A Diesel Engine Stainless Steel Sintered Felt Filter Element is a three-dimensional, porous monolithic structure fabricated from ultra-fine stainless steel fibers. Through processes of layering, compaction, and high-temperature sintering, these fibers bond at their contact points, creating a tortuous network of interconnected pores. Its primary function is to serve as the filtering medium within a Diesel Particulate Filter (DPF) to physically capture and subsequently oxidize carbonaceous soot particles from diesel exhaust gas.

Key Role: The core substrate for Diesel Particulate Filters (DPF) and Catalyzed Diesel Particulate Filters (CDPF).

Extended Use: As a structural substrate for integrated after-treatment devices, such as combined DOC+DPF or SCR-on-Filter (SCRoF) systems, enabling multi-functionality in compact packaging.

While various stainless steels can be used, Iron-Chromium-Aluminum (FeCrAl) alloys are the industry standard for high-performance applications due to their superior properties:

Exceptional High-Temperature Oxidation Resistance: Forms a protective, self-healing alumina (Al₂O₃) scale at temperatures exceeding 1000°C, crucial for surviving repeated active regenerations.

Superior Thermal Shock Resistance: The metallic ductility allows it to withstand rapid temperature cycles (e.g., from cold start to >600°C regeneration) without cracking—a critical weakness of ceramic DPFs.

Good Corrosion Resistance: Resists attack from sulfur compounds and acids present in exhaust streams.

High Mechanical Strength: Offers excellent vibration and impact resistance.

Graded Pore Structure: The felt is engineered with a pore size gradient along the gas flow path (larger pores on the inlet side, finer pores toward the outlet). This facilitates depth filtration, where particles are trapped throughout the material's thickness, leading to:

High Soot Holding Capacity

Slower Back-Pressure Increase

Very High Filtration Efficiency (>99% for PM2.5 and total particle mass)

Working Cycle:

Filtration: Exhaust gases flow through the porous wall. Soot particles are captured via mechanisms of impaction, interception, and diffusion.

Regeneration: Accumulated soot is periodically burned off to restore filter performance.

Passive Regeneration: Uses NO₂ (generated by a preceding DOC) to oxidize soot at lower temperatures (~250-450°C).

Active Regeneration: Triggers in-cylinder or post-injection of fuel to raise exhaust temperatures above 600°C, oxidizing soot via O₂.

| Feature | Stainless Steel Sintered Felt DPF | Ceramic (Cordierite/SiC) DPF |

|---|---|---|

| Mechanical Strength | Excellent. Highly resistant to vibration, shock, and physical impact. | Brittle. Prone to cracking from mechanical stress or improper handling. |

| Thermal Shock Resistance | Outstanding. No risk of thermal cracking. Highly reliable. | Poor (Cordierite) to Moderate (SiC). Thermal gradients can cause cracks. |

| Thermal Conductivity | High. Promotes even heat distribution during regeneration, preventing local hot spots and melting. | Low. Risk of localized overheating ("hot spots") leading to meltdown. |

| Canning/Mounting | Can be directly welded to the housing, ensuring a robust, leak-proof seal. | Requires fragile mat mounting systems, which can degrade over time, causing leaks. |

| Weight | Heavier | Lighter |

| Initial Cost | Higher (material & manufacturing) | Lower (mass-produced) |

| Primary Failure Mode | Gradual oxidative aging over extreme lifetimes. | Sudden catastrophic failure: cracking, melting, or severe plugging. |

Manufacturing Process: Fiber production → Graded felt layering → Compaction → Vacuum/Atmosphere Sintering → Machining to shape → Catalytic coating (if CDPF).

Maintenance & Service Life:

Effective Regeneration: High thermal conductivity ensures safer, more complete active regenerations.

Cleanability: Heavily loaded or ash-plugged filters can often be deep-cleaned via controlled thermal baking, reverse air pulse, ultrasonic, or chemical cleaning, extending service life significantly.

End of Life: Typically determined by a gradual increase in permanent pressure drop due to ash accumulation or very long-term oxidative aging of the metal, not sudden fracture.

Target Applications:

High-Reliability Demanding: Heavy-duty trucks, mining & construction machinery, military vehicles, railway locomotives.

Harsh Operating Environments: Off-highway equipment, marine engines, generator sets subject to high vibration and thermal cycles.

Industry Trends:

Finer Fibers: Use of sub-micron fibers to achieve >99.9% efficiency and meet ultra-low emission standards (e.g., Euro VII, CARB).

System Integration: Development of monolithic metal-based units combining DPF, DOC, and SCR functions.

Material Science: Development of next-generation alloys optimizing cost, performance, and durability.