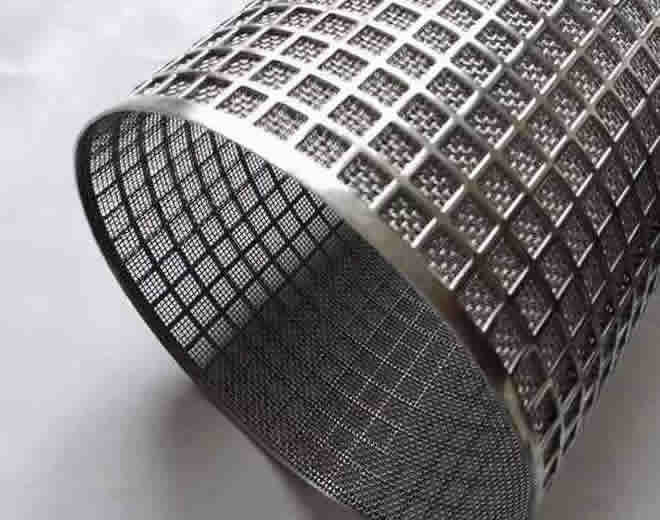

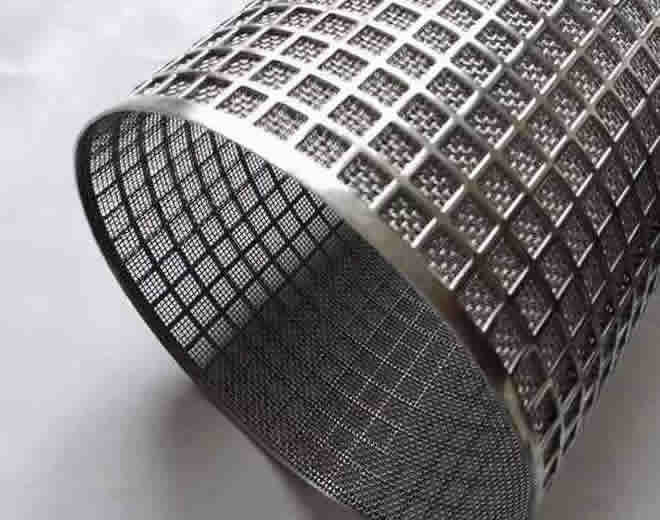

This is a "composite" + "sintered" filter cartridge. Its core lies in stacking multiple layers of stainless steel wire mesh with different mesh sizes (fineness) together, sandwiched between two critical layers of high-strength perforated plates, and then fused into a single, porous, monolithic filtering element through high-temperature vacuum diffusion sintering.

A typical five-layer structure (from outside to inside) is as follows:

Protective Layer (Outer Layer): A coarser woven mesh (e.g., 20 mesh), primarily for protection against initial fluid impact.

Control Layer / Filter Layer (Middle Layer): One or several layers of high-precision plain Dutch woven mesh (e.g., 100 mesh, 200 mesh). This is the core layer that determines the filtration rating. By precisely controlling wire diameter and pore size, a stable filtration accuracy ranging from 1 micron to 100 microns can be achieved.

Reinforcement Layer / Skeleton Layer (Inner Layer): Another layer of coarser woven mesh or plain weave mesh, providing additional support.

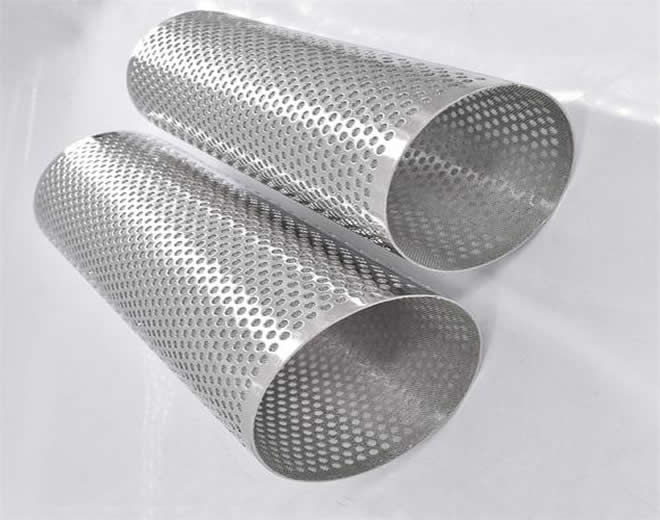

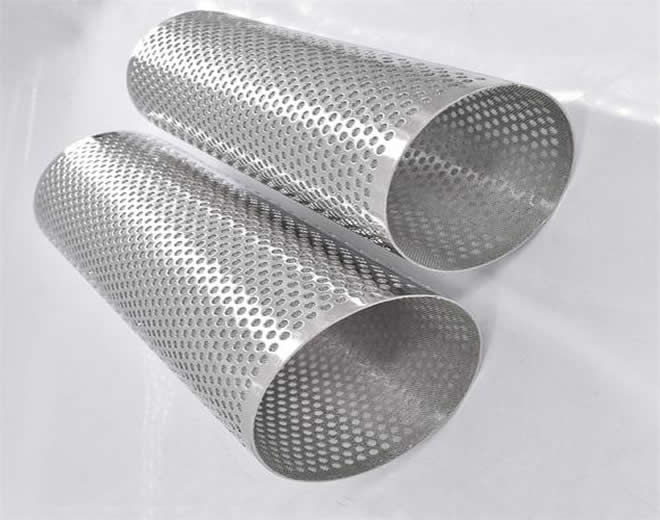

Key Component – Perforated Plates:

On the outer and inner sides of the multi-layer mesh, a layer of stainless steel perforated plate is laminated.

The perforated plate is typically 0.5-2mm thick, with regular holes (round or square), and the hole size is much larger than the filtration rating.

Function: Provides extremely high mechanical strength and rigidity, preventing the cartridge from deformation, collapse, or bending under high differential pressure; provides a solid base for welding.

The assembled "sandwich" structure is placed in a vacuum sintering furnace, heated to a temperature near the melting point of stainless steel, and held. During this process, the intersecting points of the metal wire mesh fuse and diffuse into each other, forming a strong metallurgical bond, transforming into a rigid, porous, monolithic whole with no risk of delamination between layers.

Exceptionally High Mechanical Strength and Pressure Resistance: Thanks to the perforated plate skeleton and sintered monolithic structure, it can withstand very high differential pressures (up to several MPa) and repeated backwashing. It absolutely does not have the risk of "pleat collapse" or "delamination" like pleated filter cartridges.

Stable Filtration Rating and Depth Filtration: The rating is determined by the control mesh, making it very stable. It employs three-dimensional mesh depth filtration, where particles are trapped within the internal structure of the medium, resulting in an extremely high dirt holding capacity and long service life.

Excellent Backwashing and Regeneration Performance: Due to its extreme strength, it can withstand powerful backwashing with high-pressure water, air, ultrasonic cleaning, and even acid/alkali chemical cleaning, offering excellent regeneration and a very long overall lifespan.

Excellent Thermal Stability and Corrosion Resistance: All-stainless-steel construction withstands high temperatures (related to material, 316L up to 400°C+) and corrosion, suitable for extreme conditions.

No Media Migration: Contains no internal binders; sintered into a monolithic structure, guaranteeing absolutely no fiber or particle shedding, ensuring downstream fluid cleanliness. This is critical for electronics and pharmaceutical industries.

Good Weldability: The perforated plate end faces allow for easy plasma welding or laser welding with stainless steel end caps, creating a perfect metal seal with no leakage risk, and can withstand high-temperature sterilization (SIP).

Suitable for applications with extremely high demands for strength, rating stability, and reliability:

Polymer Melt Filtration: e.g., chemical fiber, plastic extrusion lines (high pressure, high temperature, high viscosity).

High-Temperature Gas Filtration: Coal gas, hot air, flue gas dust removal.

Hydraulic Oil and Fuel Systems: Precision filtration in high-pressure lines for aircraft, ships, heavy machinery.

Catalyst Recovery and Precious Metal Capture.

Pharmaceutical Industry: Filtration of fermentation broth, purified water, compressed air, suitable for in-situ steam sterilization (SIP).

Water Treatment: Pre-filtration for Reverse Osmosis (RO) systems, pre-treatment for seawater desalination.

| Feature | Perforated Plate Composite Sintered Mesh Cartridge | Stainless Steel Pleated Filter Cartridge |

|---|---|---|

| Core Structure | Multi-layer mesh + perforated plate skeleton, sintered monolithically | Single/Multi-layer mesh or felt, pleated |

| Filtration Mode | Depth Filtration: Particles trapped within the 3D network. | Surface Filtration: Particles primarily trapped on the pleat surface. |

| Mechanical Strength | Extremely High: Excellent resistance to collapse and deformation. | High, but excessive backwash pressure may cause pleat collapse. |

| Dirt Holding Capacity | Very High (stores contaminant internally in depth). | High (by increasing surface area). |

| Rating Stability | Excellent, less likely to change due to pressure fluctuations. | Good, but pleats may slightly deform under high ΔP, affecting rating. |

| Initial Pressure Drop | Relatively higher (resistance from depth structure). | Relatively lower (smooth flow channels). |

| Cost | Complex manufacturing, typically higher unit price. | Relatively lower. |

| Ideal Application | High ΔP, high viscosity, requiring depth filtration, frequent strong backwashing. | High flow rate, low ΔP, requiring large filtration area, surface filtration. |

Rating Selection: Define the minimum particle size to be removed, select the corresponding control layer rating (often expressed as absolute rating in μm).

Material Selection: 304 (general purpose), 316L (resists chloride corrosion), Hastelloy, etc.

Strength Verification: Confirm the cartridge's structural strength is sufficient based on the system's maximum operating ΔP and backwash pressure.

Cleaning Methods:

Backwashing: Most common, using clean fluid in reverse flow.

Ultrasonic Cleaning: Highly effective for removing deep-seated particles and grease.

Chemical Cleaning: Soaking in acid, alkali, or surfactants to dissolve contaminants.

High-Temperature Baking: Removes organic matter.

Integrity Testing: Regularly perform bubble point tests to monitor for cartridge damage or blockage. This is mandatory for critical processes (e.g., sterile filtration).