This refers to a high-performance, industrial-grade filter element widely used for demanding air and gas filtration applications. Its name accurately describes its construction and primary purpose.

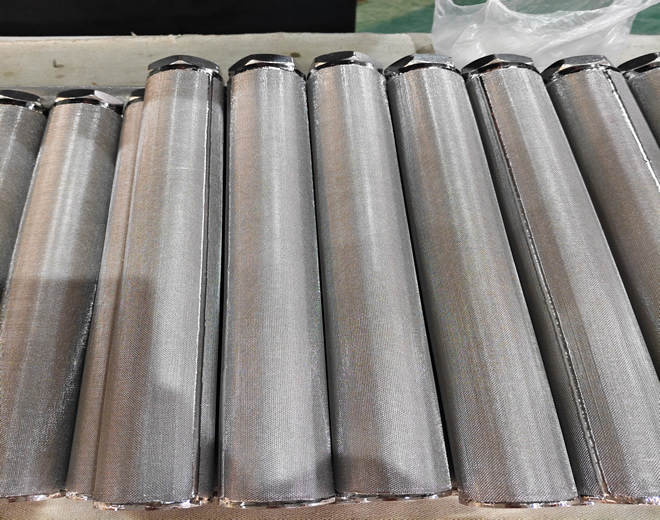

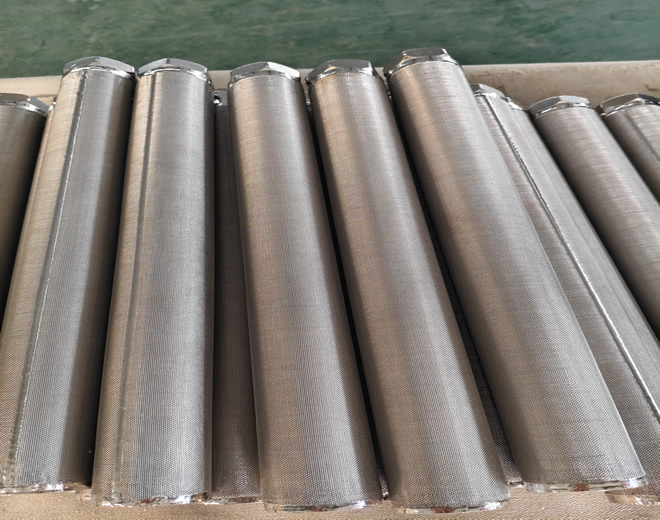

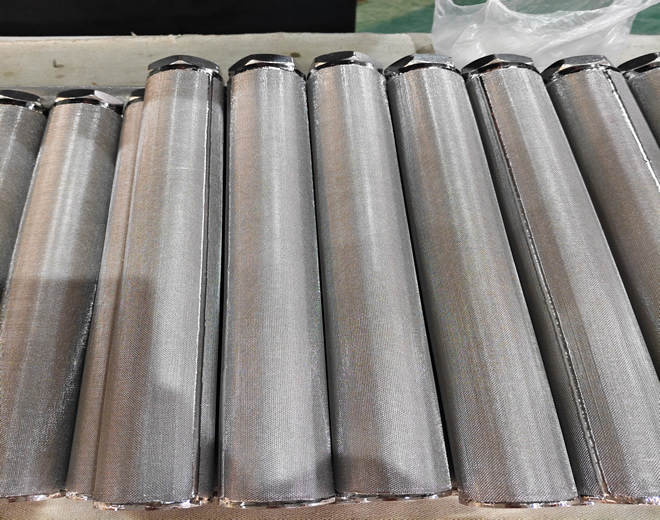

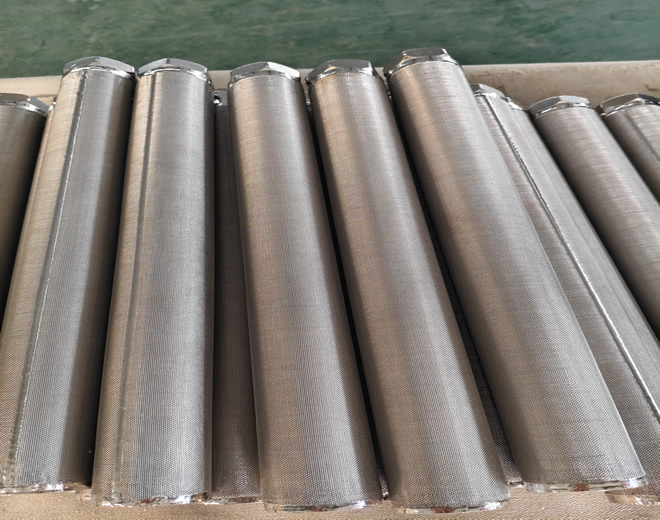

The cartridge's name precisely defines its three-layer construction:

Sintered Felt Media: The core filtration layer. Typically made from multiple layers of graded stainless steel fibers (e.g., 316L) that are laid, stacked, and fused together in a high-temperature vacuum sintering process. This creates a three-dimensional, porous matrix with a gradient pore structure, offering high porosity for good flow and depth filtration capability.

Dual Protective Wire Mesh: The structural support and guard.

Inner Mesh: Located on the core side, it provides structural support to prevent the cartridge from collapsing under high differential pressure.

Outer Mesh: Located on the outer surface, its primary role is mechanical protection against handling damage, cleaning, or fluid impact during operation.

Material: Usually stainless steel, welded integrally with the felt media for robust construction.

High Filtration Efficiency: Uniform pore structure allows for precise filtration ratings, typically ranging from 2 to 200 microns.

High Dirt Holding Capacity: The 3D depth-loading design traps contaminants throughout the media thickness, not just on the surface, leading to long service life.

Exceptional Strength & Durability: All-metal construction offers high mechanical strength, withstanding significant pressure differentials (often 1-3 MPa+). It is highly resistant to wear, fatigue, and thermal shock.

Excellent Cleanability & Reusability: Can be regenerated using methods like reverse pulse cleaning, ultrasonic cleaning, or chemical washing. This makes it a reusable cartridge, offering lower long-term cost.

High Temperature & Corrosion Resistance: Stainless steel construction withstands high temperatures (typically 400-600°C) and resists a wide range of corrosive chemicals.

Low Initial Pressure Drop: High porosity ensures minimal flow resistance, reducing energy consumption.

It operates on the principle of depth filtration. As contaminated air/gas flows through the porous wall of the cartridge:

Larger particles are trapped on or near the surface.

Finer particles migrate into the depth of the media and are entrapped within the complex, interconnected pore channels.

Clean gas exits from the core of the cartridge.

This cartridge is critical in industries requiring ultra-clean, reliable air or process gas.

| Industry Sector | Typical Applications | Key Demands Met |

|---|---|---|

| Chemical & Petrochemical | Process gas purification (catalyst protection, inert gases), compressed air drying systems. | Corrosion resistance, high temperature tolerance, explosion-proof. |

| Power Generation | Gas turbine inlet air filtration, flue gas treatment, nuclear ventilation. | High reliability, efficiency, thermal stability. |

| Metallurgy | Pulverized coal injection, furnace emissions, pneumatic system protection. | Abrasion resistance, high temperature capability. |

| Pharmaceutical & Biotech | Sterile process air, fermenter inlet air, vent gas filtration. | Cleanability, sterility, non-shedding. |

| Food & Beverage | Product contact compressed air (e.g., packaging, mixing), process air. | Sanitary design, cleanable, compliant with food safety standards. |

| Electronics & Semiconductor | Cleanroom HEPA/ULPA pre-filters, high-purity process gases. | Ultra-high efficiency, low particle shedding. |

| Environmental & Energy | Waste incineration flue gas, biogas upgrading, VOC recovery. | Chemical resistance, durability in harsh conditions. |

Filtration Rating: Choose based on the required downstream protection or final gas purity level.

Material Selection: 316L is standard. For more corrosive environments, consider alloys like Hastelloy or Inconel.

Dimensions & Gasket: Must match the filter housing for a proper seal.

Clean-in-Place (CIP) / Service Life: Monitor the differential pressure (ΔP). Clean when ΔP reaches 2-3 times the initial clean ΔP. Replace the cartridge when cleaning no longer restores acceptable performance.

Installation: Handle with care to avoid damaging the outer mesh or media. Ensure gaskets/seals are correctly installed to prevent bypass.