In industrial filtration, when facing harsh operating conditions with high contaminant concentrations and heavy particulate loads, standard filter cartridges often clog rapidly, leading to frequent downtime for replacements. This severely impacts production efficiency and increases costs. The High Dirt-Holding Capacity Sintered Felt Filter Cartridge, with its unique physical structure and deep-bed filtration mechanism, functions like an efficient "industrial contaminant reservoir." It maintains excellent filtration precision while dramatically extending service cycles, providing the ultimate solution for high-contamination challenges.

"Dirt-holding capacity" refers to the total mass of contaminants a filter cartridge can capture and retain before reaching its maximum allowable pressure drop. The core of the high dirt-holding capacity sintered felt cartridge lies in its three-dimensional random fiber network structure.

True Depth Filtration:

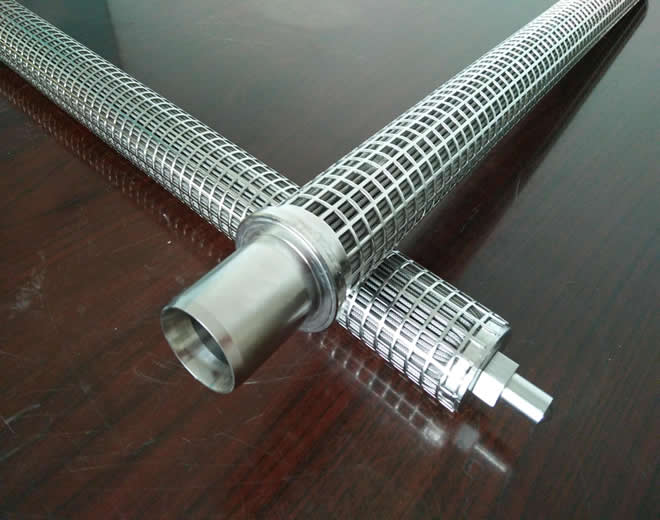

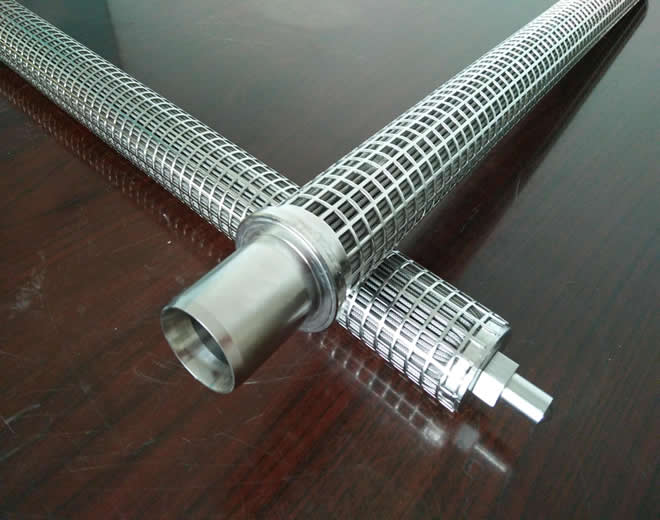

Unlike sintered wire mesh, which primarily relies on surface interception, sintered felt is formed by countless metal fibers randomly intertwined and sintered at high temperatures.

This creates tortuous, interconnected, three-dimensional labyrinthine pores within the material. Contaminants (especially fine particles) are deeply captured and retained within the vast internal space of the media as the fluid passes through.

Large Effective Filtration Area and High Porosity:

The complex fiber network provides an enormous specific surface area and a porosity typically ranging from 70% to 90%.

This means the cartridge possesses a massive "storage capacity" for contaminants, rather than merely forming a thin filter cake on the surface.

Graded Pore Structure (Optional Enhancement):

To further optimize dirt-holding capacity, high-performance sintered felts often employ a multi-layer graded pore structure: The upstream side features relatively larger pores to intercept large particles and guide flow; the middle layer serves as the precision filtering layer; the inner layer provides support. This design enables graded particle capture, utilizing the full thickness of the media and preventing premature surface blockage.

Unification of High Precision and Long Life:

It breaks the traditional trade-off between high precision and short life. Since contaminants are distributed throughout the depth rather than concentrated on the surface, the increase in pressure drop is very gradual. This allows for ultra-long continuous operation while maintaining high filtration precision (e.g., 1-30µm).

Good Mechanical Strength and Cleanability:

The high-temperature sintering process provides sufficient rigidity to withstand high-pressure differentials.

Despite being a depth filter, a significant portion of deeply embedded contaminants can still be effectively removed through robust methods like high-pressure back-pulsing, ultrasonic cleaning, or thermal pyrolysis, enabling multiple reuses and further amplifying its long-life economic value.

This type of cartridge is the ideal choice for high-contamination, high-load applications:

Chemical & Petrochemical Industry: Fine recovery of catalyst powders, terminal filtration of polymer fluids, filtration of high-solid-content slurries.

Metallurgy Industry: Online purification of molten metals (e.g., aluminum, copper, zinc) to deeply remove micron-scale inclusions.

Energy & Environmental Protection: Front-end or terminal dedusting of hot coal gas and flue gases with high dust loads requiring long operational cycles.

Water Treatment: Treatment of industrial wastewater containing high levels of suspended solids and colloidal particles.

Powder Industry: Collection and recovery of high-value powders (e.g., titanium, cobalt) requiring extremely high yield rates.

| Characteristic | High Dirt-Holding Capacity Sintered Felt Cartridge | High-Precision Sintered Wire Mesh Cartridge |

|---|---|---|

| Filtration Mechanism | Depth Filtration | Surface Filtration |

| Dirt-Holding Capacity | Extremely High (Core Advantage) | Relatively Low |

| Initial Pressure Drop | Low | Low |

| Rate of Pressure Drop Rise | Slow and Gradual | Rapid (sharp rise after surface blinding) |

| Sensitivity to Contaminant Load | Less sensitive to high concentrations; more adaptable | Easily and rapidly blinded by high concentrations |

| Cleaning/Regeneration | Cleanable, but deeper contaminants require more vigorous methods | Very easy to clean; surface contaminants are easily removed |

| Suitable Operating Conditions | High contaminant concentration, pursuit of long cycles | Relatively lower contaminant concentration, requiring absolute precision and easy maintenance |

Balance Precision and Capacity: Clearly define the minimum particle size to be removed (precision). Among cartridges with the same rating, choose one with higher porosity and an optimized graded structure for maximum dirt-holding capacity.

Focus on the Pressure Drop vs. Time Curve: Suppliers should provide simulated pressure drop growth data under operating conditions, which is a key indicator for evaluating dirt-holding capacity.

Plan Cleaning Strategy: Due to its depth-loading nature, an effective offline cleaning plan (e.g., ultrasonic cleaning) is necessary to fully realize its reusable value.

Verify Structural Strength: For high-contamination duties, ensure the cartridge has sufficient mechanical strength to withstand potential instantaneous shock loads.

The high dirt-holding capacity sintered felt filter cartridge is an outstanding embodiment of filtration engineering philosophy: it does not passively endure contamination but actively manages and contains it. Through its deep three-dimensional structure, it transforms the filtration process from an easily blinded "surface event" into a predictable and manageable "volumetric process."

Choosing it means selecting for your production system:

Reduced Downtime

Lower Filter Replacement and Maintenance Costs

More Stable System Operating Pressure

Strong Tolerance for Harsh Operating Conditions

In today's pursuit of continuous, efficient, and stable production, the high dirt-holding capacity sintered felt filter cartridge is not merely a filter; it is a strategic buffer and core barrier ensuring the smooth operation of your production process.