In the field of modern industrial filtration, the Stainless Steel Backwash Filter Cartridge (also known as the Clean-in-Place (CIP) Filter Cartridge) is becoming the preferred solution for high-end process filtration due to its exceptional regenerability, ultra-long service life, and extremely low total cost of operation. It is not merely a filter element but the core component of an intelligent filtration system that embodies the principles of sustainable production.

This is a high-performance filter cartridge that utilizes multi-layer sintered stainless steel wire mesh or sintered metal fiber felt as the filtration medium. Its special structural design allows fluid to pass through at high velocity in the opposite direction of normal flow, thereby forcibly dislodging and discharging contaminants trapped within and on the surface of the cartridge.

Key Feature: "Clean-in-Place" means the cleaning process requires no disassembly of the cartridge, no system shutdown, and no opening of the filter vessel. The system can operate continuously, with regeneration achieved merely by switching valves, maximizing production uptime.

Its operational cycle consists of two core phases:

1. Forward Filtration Phase (Filtration Cycle)

Flow Direction: The fluid to be filtered flows from the outside to the inside of the cartridge.

Process: Suspended solid particles are trapped on the surface and within the depth of the cartridge's porous structure.

Status: The pressure differential (ΔP) across the filter inlet and outlet gradually increases.

2. Reverse Cleaning Phase (Backwash Cycle)

Trigger: Initiated automatically or manually by the control system when the ΔP reaches a preset value (typically 0.1-0.5 MPa / 15-75 psi).

Flow Reversal: A clean flushing medium (liquid or gas) flows at high velocity from the inside to the outside of the cartridge.

Scouring Action: The reverse flow creates powerful shear forces and a slight media expansion, loosening and dislodging deeply embedded contaminants.

Discharge: The dislodged debris is rapidly expelled from the system through the blow-down valve.

3. Return to Filtration: The backwash process lasts only seconds. Valves switch back to filtration mode, and the cartridge regains over 90% of its initial filtration capacity, with the ΔP dropping to near its clean state.

Filtration Media:

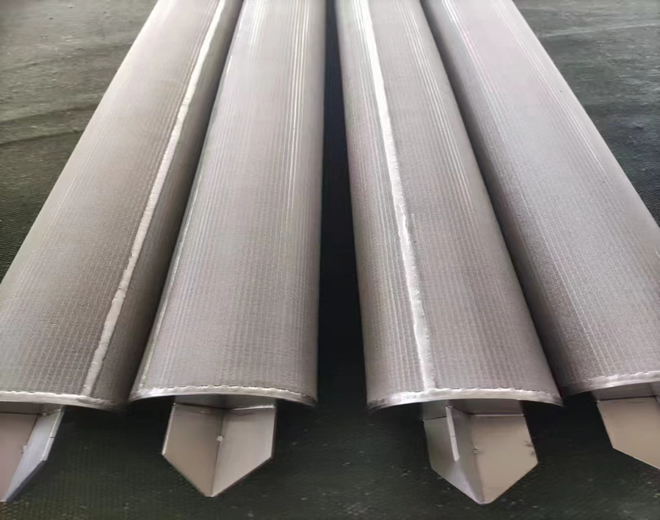

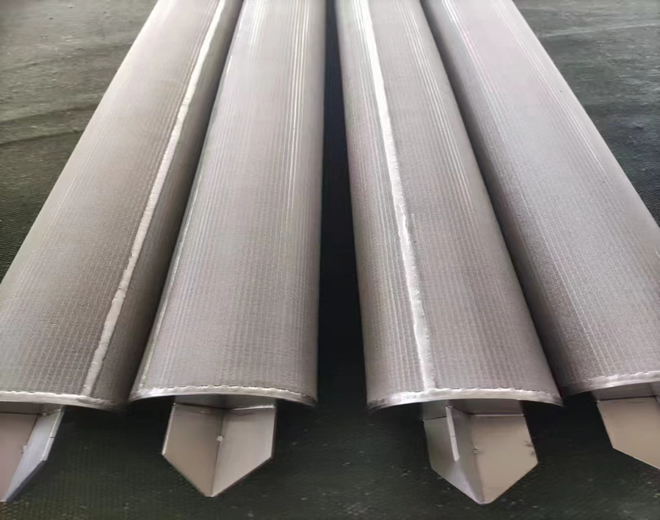

Multi-Layer Sintered Stainless Steel Mesh: The mainstream choice, combining high strength, high accuracy, and excellent backwash recovery. The standard 5-layer structure (protective/filtration/separator/support/protective) ensures deep dirt-holding capacity and anti-deformation.

Stainless Steel Sintered Felt: Made from micron-sized metal fibers sintered randomly, offering higher porosity and exceptional dirt-holding capacity, especially suitable for viscous fluids.

Composite Structure: A combination of mesh and felt, balancing strength and dirt-loading.

Key Structural Features:

Perforated Center Tube/Core: Provides the flow path for reverse flushing and ensures structural integrity.

All-Metal, Binder-Free Construction: Monolithic sintering withstands high temperatures, thermal shock, and chemical corrosion, with no risk of media migration.

Precision Welding: End caps are welded to the media to guarantee zero bypass and withstand bidirectional pressure.

Ultra-Long Service Life & Cost-Effectiveness: A one-time investment, capable of being regenerated hundreds or even thousands of times. The total cost of ownership is significantly lower than disposable filters (e.g., filter bags, melt-blown cartridges).

Maximized Production Continuity: Clean-in-Place operation enables 7x24 uninterrupted operation, greatly improving equipment utilization and output.

Exceptional Filtration Performance:

High Filtration Rating: Can reliably achieve absolute ratings from 1 micron to 100 microns.

High Dirt-Holding Capacity: The three-dimensional depth filtration structure holds several times to several dozen times more contaminant than surface filters.

High Strength: Withstands forward/reverse pressure differentials up to several MPa and mechanical shock.

Broad Compatibility:

Temperature Resistance: Suitable for extreme environments from -200°C to +500°C.

Corrosion Resistance: Materials like 316L can withstand most acids, alkalis, organic solvents, and corrosive process media.

Material Compatibility: No media shedding, meeting high-purity requirements for food, pharmaceutical, etc.

Environmental Sustainability: Drastically reduces solid waste (spent cartridges) and material consumption, aligning with clean production and circular economy principles.

Petrochemicals: Polymerization catalyst recovery, process gas purification, solvent filtration, start-up protection.

Fine Chemicals/Pharmaceuticals: Activated carbon recovery, catalyst support separation, crystallizer product filtration, API intermediate filtration.

Food & Beverage: Precision filtration of syrups, edible oils, wines, beverages; compatible with CIP systems.

Power & Metallurgy: Secondary loop water filtration in nuclear plants, turbine lube oil filtration, hydraulic system protection, metalworking fluid purification.

Water Treatment: Pre-filtration for seawater desalination, water reuse, guard filter for membrane systems (RO/UF).

Gas Processing: Particulate removal from compressed air, industrial gases, and flue gas.

Successful application requires comprehensive evaluation:

System Compatibility: Must be paired with a dedicated Backwash Filter Housing and supporting valves and control system (fully/semi-automatic).

Parameter Determination:

Filtration Rating: Determined by downstream protection requirements.

Backwash Medium & Parameters: Commonly clean water, compressed air, or raw fluid. Pressure (typically 0.3-0.6 MPa), flow rate, and duration are critical.

Contaminant Characteristics: The hardness and adhesiveness of particles determine backwash efficacy. For greasy, sticky substances, hot media or chemical-assisted cleaning may be needed.

Maintenance Considerations: Although cleanable in-place, irreversible fouling may occur over extended periods. Periodic offline deep cleaning (e.g., ultrasonic cleaning, chemical soaking) is required for complete performance restoration.