Description

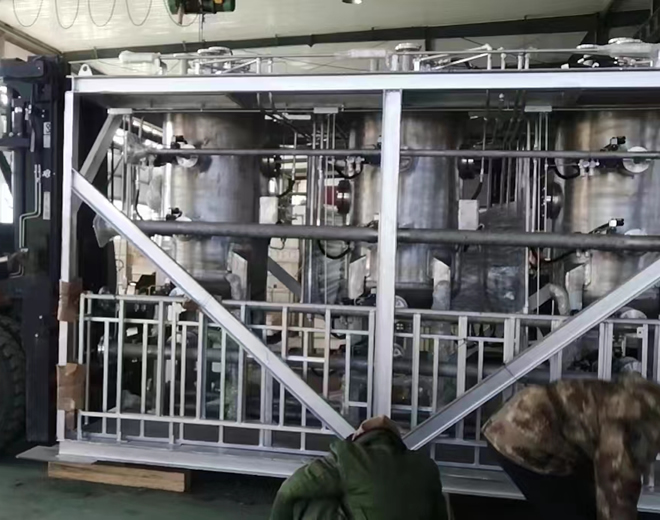

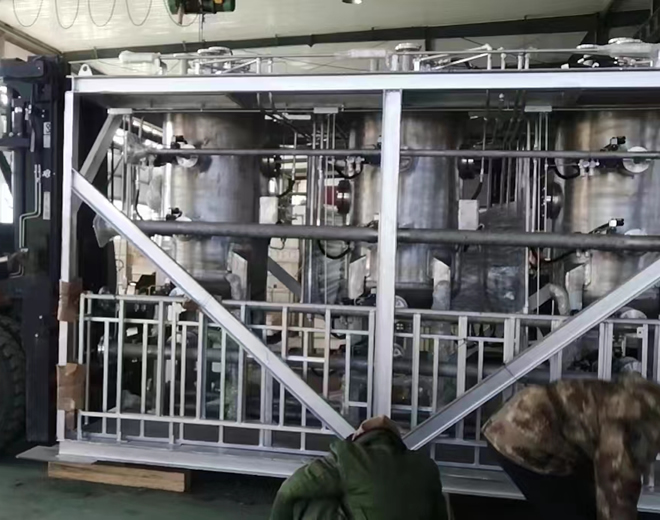

I. Overview

The VFS filtration system, produced with imported technology, is a new type of filtration equipment designed for the automatic continuous

filtration and continuous slag discharge of viscous petrochemical pulps. Widely used in pharmaceuticals, petroleum, chemicals, and food

industries for the treatment of high-viscosity liquids, this filter is an essential piece of equipment.

II. Working Principle

Untreated liquid is pumped into the filter cylinder from the top, and solid particles are intercepted by the wedge-shaped mesh. When the

filter cake reaches a certain thickness, the system starts the cleaning device. The cleaned filter residue is pushed to the bottom of the tank's

residue compartment. When the residue reaches the set position, the discharge valve opens to discharge the residue. The structure ensures

that the residue (with lower density than the unfiltrated liquid) does not suspend due to gravity, liquid level pressure, and filtration pressure. The

moisture content of the tank residue can reach 80% due to the combined action of gravity, liquid level pressure, and filtration pressure. When

the set residue amount is reached, the discharge valve opens for residue discharge (opening time: 1-2 seconds, or set as timed), and then the

residue is sent to a sealed storage tank by a screw feeder (optional).

III. Structural Introduction

1.Filtration tank

2.Pneumatic actuator

3.Filter element

4.Cleaning components

5.Discharge pneumatic valve

6.Electrical control system

IV. Technical Parameters

1.Filtration of viscous chemical materials.

2.Filtration of paints and water-based coatings.

3.Filtration of various colloids, including sealants.

4.Filtration of various additives in papermaking processes (starch, calcium carbonate, etc.).

5.Liquid filtration in wet powder manufacturing processes (replacing vibrating screens).