Description

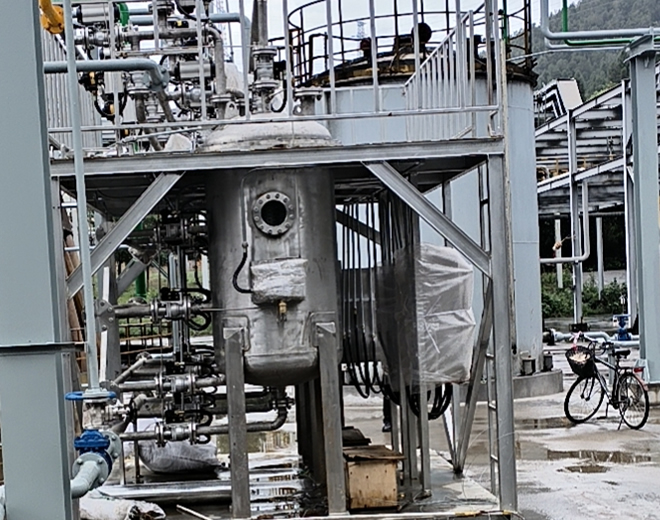

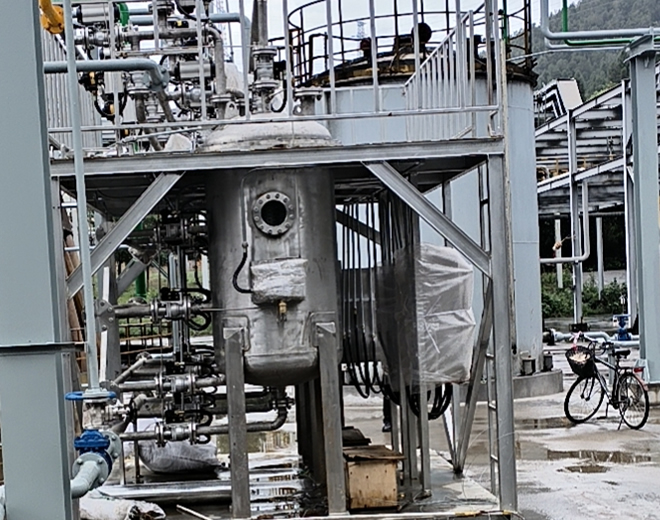

I. Overview

TFS filtration systems have a simple structure and flexible form. The number of filtration units can be adjusted based on process flow and

colloidal content. The filter elements inside the unit use stainless steel sintered mesh or sintered felt, which is sintered through special welding,

providing high porosity, strong particle retention, high strength, long life, and easy backwashing. This system features thorough backwashing,

minimal oil discharge, and high automation. This system has found extensive use in the filtration of clear water in paper mills, as well as in

organic chemistry, pharmaceuticals, edible oils, wastewater treatment, and other industries.

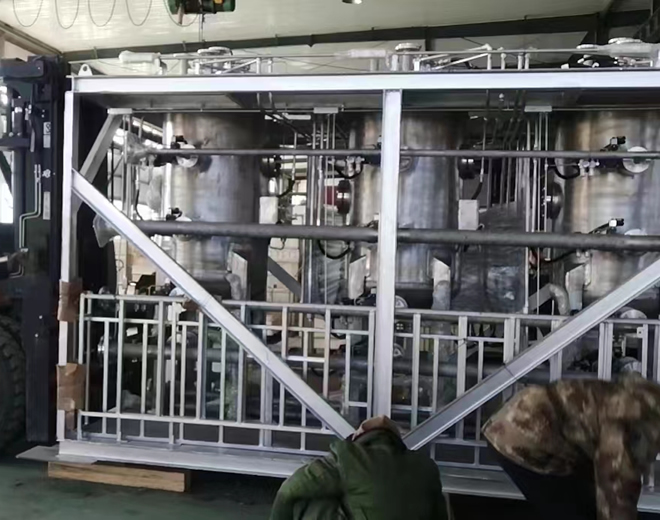

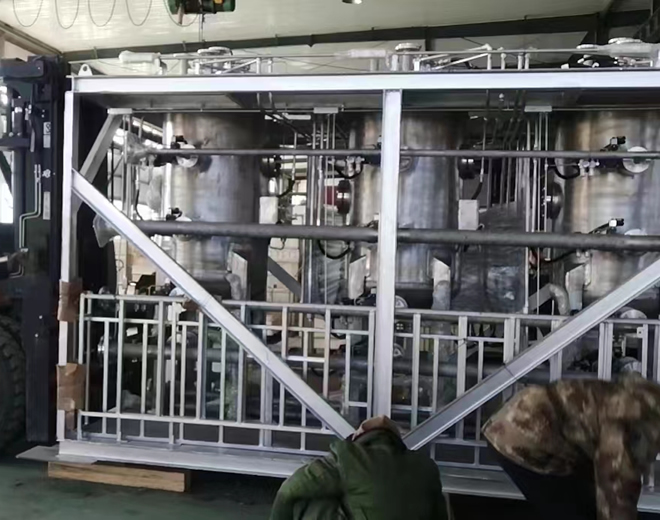

II. Structural Introduction

1.Two sets of filtration tanks and internal components.

2.Air piping and automatic control valves, measuring instruments

3.Control box and software programs.

4.Steel frame.

*Based on requirements, an oil storage tank and washing liquid tank can be selected, and manual or fully automatic operation can be chosen.

Manual operation excludes items 2 and 3, and valves are manual.

III. Features

1.Automatic backwashing for continuous and uninterrupted filtration.

2.Flexible structure, easy addition of filtration units.

3.Automatic online backwashing without manual disassembly of filter elements.

4.Applicable to various liquids and contaminants, including viscous liquids and colloidal substances.

5.Suitable for high-temperature liquids (-40°C to 350°C).

6.Suitable for high-precision filtration, including backwashing for clarification filtration.

7.Normal operation under varying processing volumes and high pollutant concentrations.

8.Minimal discharge of contaminated liquid.

9.Thorough filter cleaning, long service life (maintenance-free for one year).

10.Fully enclosed tank-type static sealing equipment, leak-free, clean, and safe.

11.PLC control with remote data transmission and monitoring for filtration time analysis and fault alarms.