Description

I.Introduction

The self-cleaning filter series is a set of products designed and manufactured by our company using American technology. The key

component, the filter element, incorporates cutting-edge technology and processes, guided and produced under the supervision of American

experts. The performance of this product has reached the level of similar products in advanced countries such as the United States and Japan.

This product can effectively and reliably remove mechanical impurities from industrial circulating water and other liquids, making it widely

applicable in various industries.

II.Process Principles

The self-cleaning filter adopts the principle of automatic cleaning, including the following steps:

1.Filtration: When fluid passes through the filter, impurities and particles are trapped by the filter medium. The aperture size of the filter

medium can be selected according to actual needs to meet the filtration requirements of different particle sizes.

2.Pressure difference detection: Over time, impurities on the filter medium gradually increase, forming a pressure difference. The pressure

difference sensor monitors changes in the pressure difference on the filter medium. When the pressure difference reaches a certain threshold,

the self-cleaning filter proceeds to the next operation.

3.Cleaning: The cleaning process includes online cleaning and offline cleaning. Online cleaning is performed while the filter is in operation,

and the cleaning liquid is sprayed onto the filter medium through specific nozzles or rotary arms to flush out clogged particles. Offline cleaning

is performed when the filter is not in operation. The cleaning liquid is injected from above or below the filter medium through the discharge

valve to wash away impurities.

4.Discharge: After cleaning, the self-cleaning filter removes clogged particles by discharging sewage or liquid through the discharge valve,

maintaining the unobstructed operation of the filter.

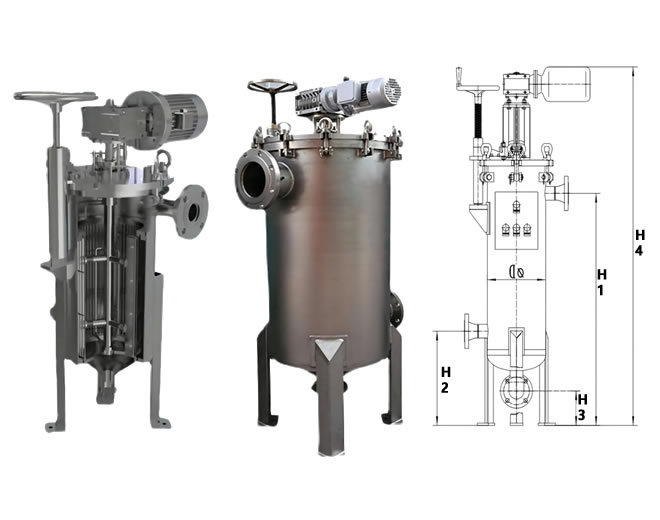

III.Equipment Composition

HIM self-cleaning filter mainly consists of the following components:

1.Filtration unit: Includes filter screens, filter cartridges, or filter discs to trap impurities and particles.

2.Cleaning system: Includes nozzles, rotary arms, cleaning liquid supply pipelines, etc., to clean clogged substances on the filter medium.

3.Control system: Includes pressure difference sensors, control valves, discharge valves, etc., to monitor pressure differences, control the cleaning process, and discharge operations.

4.Sewage treatment system: Includes discharge pipelines, treatment equipment, etc., for processing discharged sewage or liquid.

IV.Equipment Parameters