Description

I.Introduction

The scraper filter is a crucial industrial filtration device used in the liquid-solid separation process. It finds widespread applications in

various industries, including chemical, pharmaceutical, food and beverage, and wastewater treatment. The primary function of the scraper filter

is to efficiently filter and separate solid particles from liquids using a scraping mechanism. The following is a detailed introduction to the scraper

filter:

II.Working Principle

The working principle of the scraper filter is based on the fundamental principles of screening and separation. It comprises a filtration

medium, typically a fine-pore filter cloth or stainless steel mesh. The liquid passes through this filtration medium, while solid particles are

blocked on the surface of the medium. The key component is the scraper system, consisting of scraper blades or blades that mechanically

approach the surface of the filtration medium, scraping off solid particles and pushing them toward the collection system. The clean liquid

passes through the filtration medium, ultimately obtaining a separated solid-liquid product.

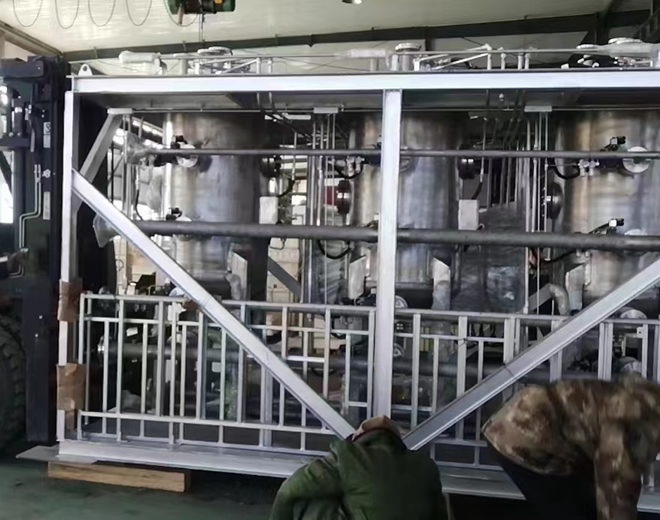

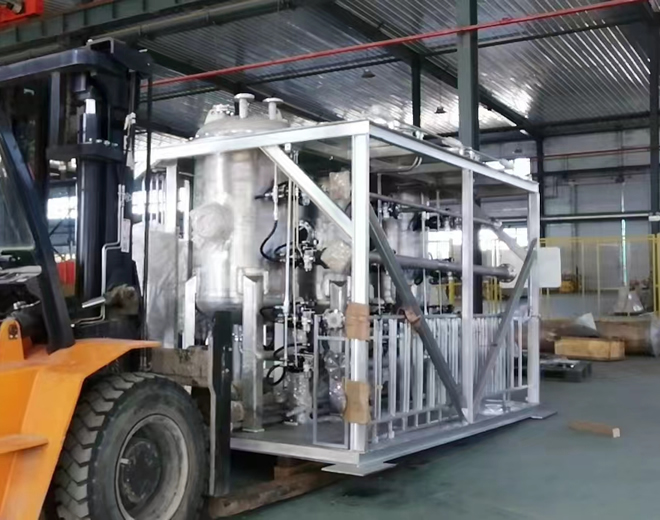

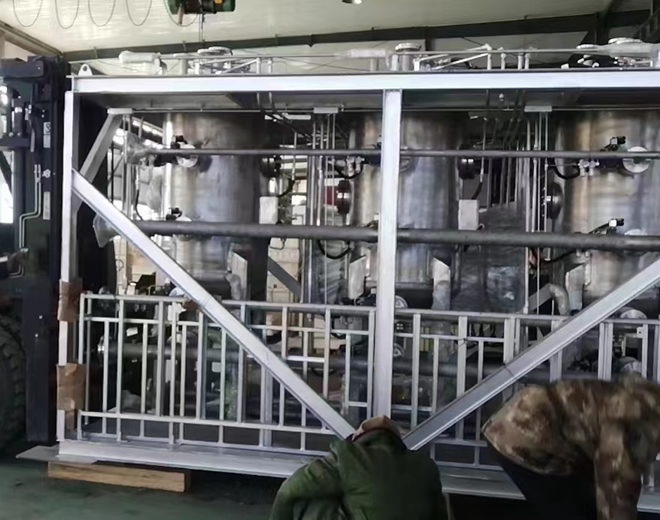

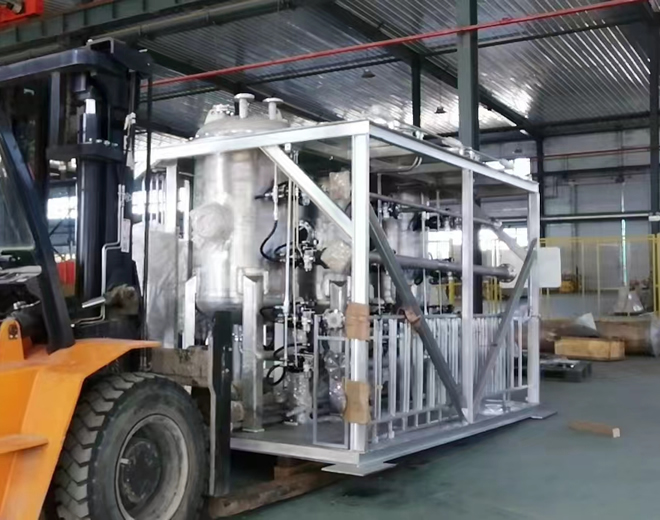

III.Components

1.Filtration medium: The filtration medium is usually a layer of fine-pore filter cloth or a metal mesh. The choice depends on application

requirements. These media have precise aperture sizes to capture specific-sized solid particles.

2.Scraper system: The scraper system typically consists of a motor, scraper blades, and guiding devices. The scraper blades approach the

surface of the filtration medium to ensure effective removal of solid particles. The speed, pressure, and angle of the scraper can be adjusted

according to the application.

3.Collection system: The collection system is used to gather and discharge the scraped-off solid particles for further processing or

disposal. It typically includes collection troughs, conveying equipment, or discharge devices.

IV.Advantages

1.Efficient Separation: Scraper filters can efficiently separate solid particles from liquids, ensuring the quality of the product.

2.Precise Control: Operators can adjust the speed, pressure, and angle of the scraper to meet the needs of different applications.

3.Wide Applicability: Scraper filters are suitable for handling viscous liquids, high-concentration suspensions, and large-particle solids.

4.Maintenance Simplicity: Compared to some other filter types, scraper filters are generally easier to maintain.