Description

I. Overview:

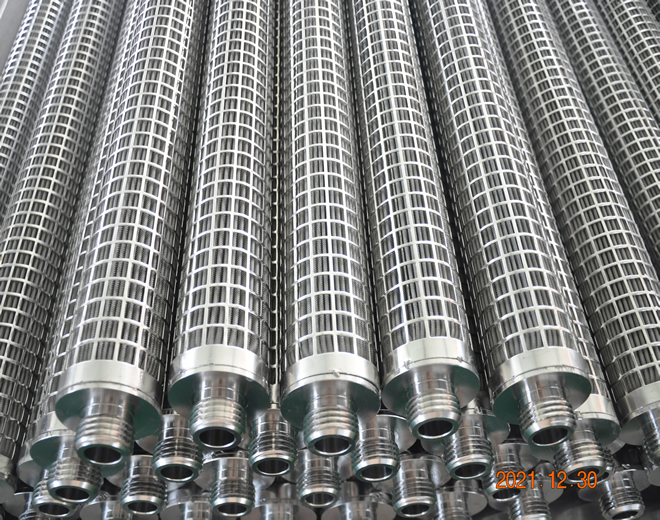

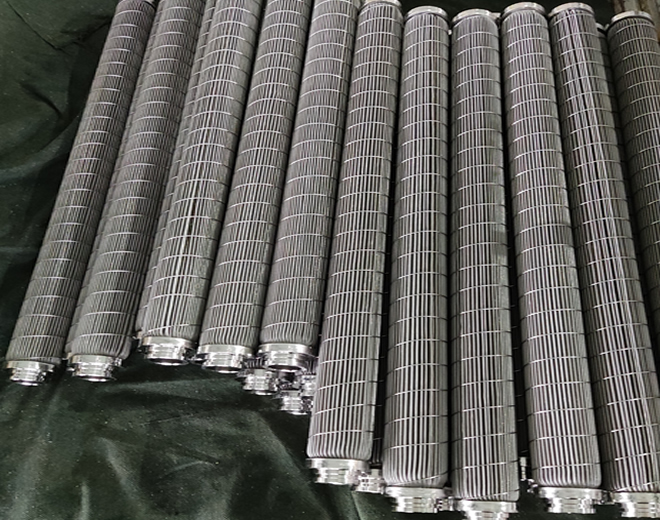

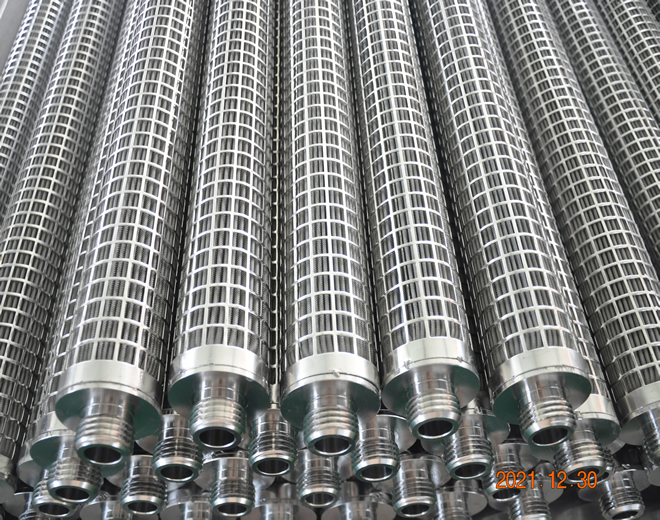

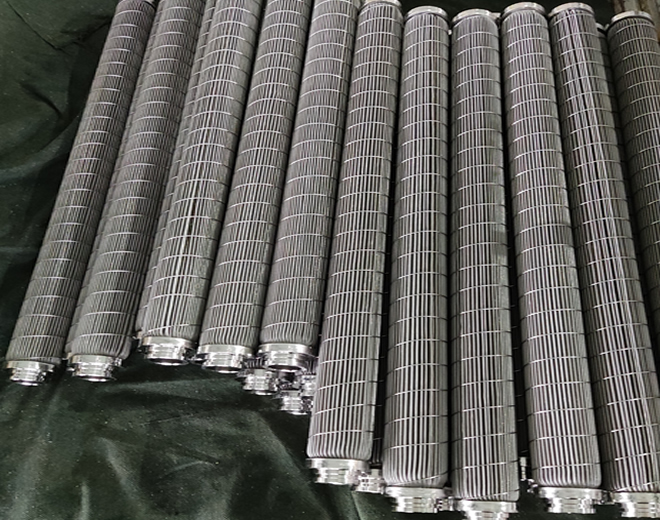

The main filtering material of the sintered mesh filter cartridge is a standard five-layer sintered mesh, formed by stacking and vacuum

sintering five layers of stainless steel wire mesh. The resulting filter cartridge exhibits strong corrosion resistance, good permeability, high

strength, easy cleaning and backwashing, precise filtration accuracy, hygienic and clean filter material, and prevents wire mesh detachment.

The main connection methods include standard interfaces (such as 222, 220, 226), quick interfaces, threaded connections, flange connections,

rod connections, and custom interfaces. It is applied in the filtration of polyester, water treatment, oils, pharmaceuticals, food and beverages,

chemical, and synthetic fiber products, as well as high-temperature air and other media.

II. Structure and Characteristics:

1.The standard five-layer mesh consists of a protective layer, precision control layer, dispersion layer, and multiple reinforced layers.

2.High strength: After sintering five layers of wire mesh, it exhibits extremely high mechanical and pressure strength.

3.High precision: Uniform surface filtration performance for particle sizes ranging from 2 to 200 micrometers.

4.Heat resistance: Can withstand continuous filtration from -200°C to 650°C.

5.Cleanability: The surface filtration structure with excellent backwashing effect ensures easy cleaning.

III. Specific Examples:

1.Precision filtration of various hydraulic oils in the mechanical industry.

2.Filtration and purification of various polymer melts in the synthetic film industry.

3.Filtration of high-temperature and corrosive liquids in the petrochemical industry.

4.Filtration and washing of materials in the pharmaceutical industry.