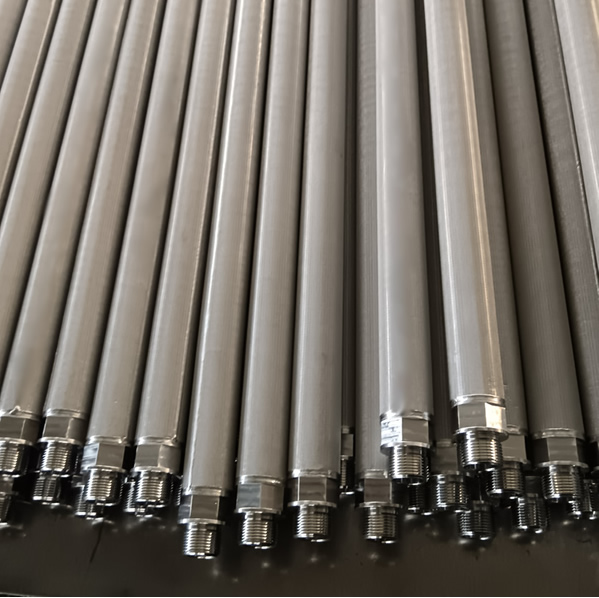

Stainless steel sintered mesh filter elements play a crucial role in the food industry, primarily functioning to filter and purify liquids and gases to ensure the safety and quality of food products.

Their excellent mechanical properties and corrosion resistance make them widely applicable across various food processing and production stages.

1. Enhancing Product Purity

During food production, raw materials and processing stages can introduce impurities such as microorganisms, suspended solids, and chemicals.

Stainless steel sintered mesh filter elements effectively remove these contaminants, thereby improving the purity of the final products. For example, in beverage production,

the filter can eliminate bacteria and solid particles from water, ensuring the hygiene and safety of the drinks.

2. Protecting Equipment

Sintered mesh filter elements prevent solid particles and impurities from entering production equipment, reducing wear and the risk of malfunctions.

In processes such as brewing and dairy processing, the application of these filters effectively prevents clogging in pipes and pumps, ensuring continuous operation of the production line and lowering maintenance costs.

3. Adapting to High Temperature and Pressure Environments

Food processing often requires high temperatures and pressures. Stainless steel sintered mesh filter elements exhibit excellent resistance to these conditions, maintaining stable filtration performance.

This makes them particularly important in applications like heat treatment and steam filtration.

4. Environmental Friendliness and Reusability

Stainless steel sintered mesh filter elements not only possess good cleaning capabilities but are also reusable.

Through proper cleaning and maintenance, their lifespan can be significantly extended.

This environmentally friendly characteristic makes them increasingly popular in the food industry, helping to reduce production costs and minimize waste generation.

5. Diverse Applications

The applications of stainless steel sintered mesh filter elements are extensive, including liquid filtration, gas filtration, oil refining, beer brewing, and juice production.

In each of these applications, they deliver outstanding filtration performance, ensuring the smooth operation of production processes.

Conclusion

In conclusion, the role of stainless steel sintered mesh filter elements in the food industry is indispensable.

They enhance product purity, protect the safe operation of equipment, and offer benefits like high-temperature resistance and reusability, aligning with modern environmental standards in food production.

As food safety regulations continue to tighten, sintered mesh filter elements will play an increasingly vital role in food processing, ensuring the safety and quality of food products.