A sintered filter element is a type of filtration medium made from sintered metal or plastic particles that are fused together under heat and pressure to form a porous structure. This porous structure allows fluids to pass through while trapping solid particles, contaminants, and impurities, making it an effective filtration solution in various industries.

The process of sintering involves compacting metal or plastic powders into a desired shape, such as a cylindrical or disc-shaped filter element, and then heating them to a temperature below their melting point. During sintering, the particles bond together, creating a network of interconnected pores with controlled pore size and distribution. The resulting sintered filter element exhibits high mechanical strength, thermal stability, and chemical resistance, making it suitable for demanding industrial applications.

One of the key advantages of sintered filter elements is their uniform pore structure, which provides consistent filtration performance and high dirt-holding capacity. The controlled pore size allows for precise filtration of particles down to submicron levels, depending on the specific application requirements. This makes sintered filter elements ideal for applications where fine filtration and particle removal are essential, such as in pharmaceutical manufacturing, food and beverage processing, chemical processing, and water treatment.

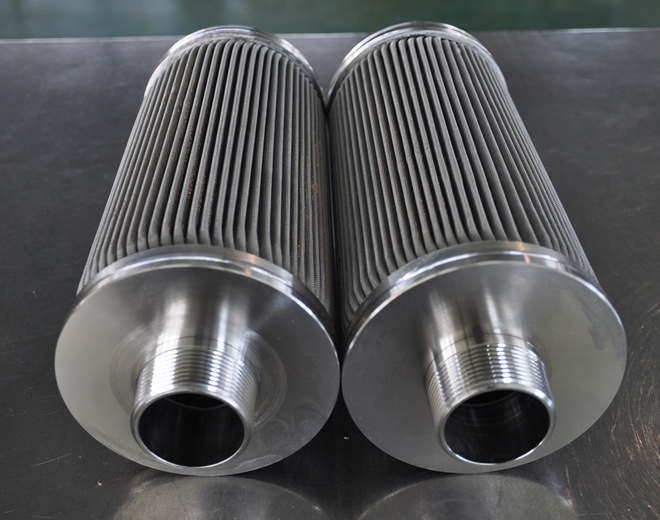

Sintered filter elements are available in various materials, including stainless steel, bronze, titanium, and polyethylene, each offering unique properties and advantages depending on the application. Stainless steel sintered filter elements, for example, are known for their durability, corrosion resistance, and compatibility with high temperatures and harsh chemicals, making them suitable for demanding industrial environments.

The versatility of sintered filter elements extends to their design options, which can include pleated configurations, cylindrical shapes, and disc formats, allowing for flexibility in installation and integration into different filtration systems. Some sintered filter elements may also incorporate additional layers or coatings to enhance their performance, such as antimicrobial coatings for applications requiring sterile filtration.

In summary, sintered filter elements are advanced filtration media characterized by their porous structure formed through the sintering process. They offer precise particle removal, high dirt-holding capacity, and durability, making them well-suited for a wide range of industrial applications where efficient and reliable filtration is essential.