A stainless steel filter element is a type of filtration medium constructed entirely from stainless steel, a corrosion-resistant alloy composed primarily of iron, chromium, nickel, and other alloying elements. Stainless steel filter elements are widely used in various industries for their durability, longevity, and ability to withstand harsh operating conditions. They are employed for the filtration of liquids and gases, offering effective particle removal and ensuring the cleanliness and purity of process fluids.

Stainless steel filter elements are available in different forms, including woven wire mesh, sintered metal powder, perforated metal sheets, and pleated metal media. Each type offers unique characteristics and advantages depending on the specific application requirements.

1. Woven Wire Mesh: Stainless steel filter elements constructed from woven wire mesh consist of multiple layers of stainless steel wire mesh screens stacked and compressed to form a porous structure. These filter elements offer precise filtration with customizable pore sizes, allowing for the removal of particles ranging from coarse to fine. They are commonly used in applications where high flow rates and moderate filtration efficiency are required, such as water treatment, chemical processing, and oil and gas filtration.

2. Sintered Metal Powder: Sintered stainless steel filter elements are manufactured by compressing and sintering stainless steel powder particles to create a porous structure with controlled pore size and distribution. These filter elements offer high filtration efficiency and uniform particle capture, making them suitable for applications requiring fine filtration and removal of submicron particles. They are commonly used in pharmaceutical manufacturing, food and beverage processing, and gas filtration applications.

3. Perforated Metal Sheets: Stainless steel filter elements made from perforated metal sheets feature a series of punched holes arranged in a pattern to allow fluid flow while retaining solid particles and contaminants. These filter elements offer high mechanical strength and are suitable for applications where coarse filtration is required, such as wastewater treatment, hydraulic systems, and air filtration.

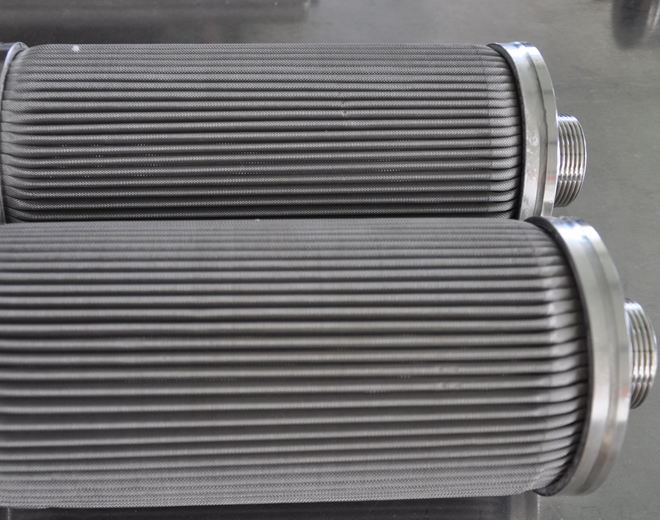

4. Pleated Metal Media: Stainless steel filter elements with pleated metal media consist of multiple layers of pleated stainless steel sheets arranged to increase the filtration area and enhance particle capture capacity. These filter elements offer high dirt-holding capacity and long service life, making them ideal for high-flow applications and environments with heavy contamination loads, such as industrial air filtration, hydraulic systems, and chemical processing.

Stainless steel filter elements offer several advantages over other filtration media, including:

- Corrosion Resistance: Stainless steel is inherently resistant to corrosion, making it suitable for use in corrosive environments and applications involving exposure to moisture, chemicals, and extreme temperatures.

- High Temperature Resistance: Stainless steel filter elements can withstand high temperatures without degrading or losing their structural integrity, making them suitable for use in high-temperature processes and applications.

- Mechanical Strength: Stainless steel filter elements exhibit high mechanical strength and durability, allowing them to withstand high pressure, vibration, and mechanical stress without failure.

- Ease of Cleaning: Stainless steel filter elements are easy to clean and maintain, allowing for repeated use and extended service life. They can be cleaned using various methods, including backwashing, chemical cleaning, and mechanical brushing.

In summary, stainless steel filter elements are versatile filtration solutions known for their durability, corrosion resistance, and high filtration efficiency. They are widely used across various industries for the filtration of liquids and gases, offering reliable particle removal and ensuring the cleanliness and purity of process fluids in demanding industrial applications.