In the design and manufacturing of precision filters, the choice of filter cartridge material is crucial as it directly impacts the filter's performance, durability, and application range. The main considerations include three common materials: stainless steel, ceramic, and polyethylene (PE), with a preference for stainless steel sintered mesh material.

1. Stainless Steel Filter Cartridge:

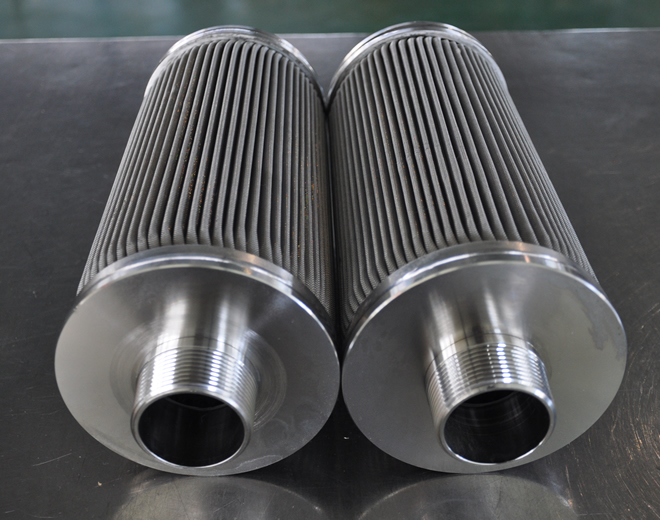

Stainless steel is a corrosion-resistant, high-temperature-resistant material with excellent mechanical properties. Stainless steel filter cartridges often adopt a sintered mesh design, where stainless steel particles are sintered together at high temperatures to form a filter cartridge with specific pore sizes. This design provides the stainless steel filter cartridge with excellent mechanical strength, pressure resistance, and effective filtration of fine particles, making it suitable for environments with high filtration precision requirements.

2. Ceramic Filter Cartridge:

Ceramic filter cartridges typically use ceramic materials with excellent corrosion resistance and high-temperature stability. The micro-porous structure of ceramic filter cartridges allows for precise filtration, ensuring effective retention of fine particles. These filter cartridges are suitable for special environments such as high temperatures, strong acids, and strong alkalis. However, they may be relatively brittle and require careful handling.

3. PE Filter Cartridge:

PE is a polymer material with good corrosion resistance and mechanical properties, lightweight, and relatively low processing costs. PE filter cartridges are suitable for applications with low filtration precision requirements or one-time use, where cost considerations are essential. However, compared to stainless steel and ceramic, PE filter cartridges may have lower pressure resistance and temperature resistance.

Advantages of Stainless Steel Sintered Mesh Material Filter Cartridge:

The stainless steel sintered mesh material filter cartridge combines the advantages of stainless steel and sintered mesh. It offers high corrosion resistance, mechanical strength, and filtration precision, making it suitable for various complex environments. The sintering process ensures a stable filter structure, guaranteeing reliable operation over an extended period. Therefore, for applications with high filtration requirements and durability in complex environments, the stainless steel sintered mesh material filter cartridge stands out as a superior choice.

Conclusion:

The selection of filter cartridge material for precision filters is crucial for their performance and application range. Among stainless steel, ceramic, and PE, the preference is given to the use of stainless steel sintered mesh material filter cartridges. This material combines the advantages of stainless steel and sintered mesh, providing excellent corrosion resistance, mechanical strength, and filtration precision, making it well-suited for demanding filtration tasks in various complex environments.