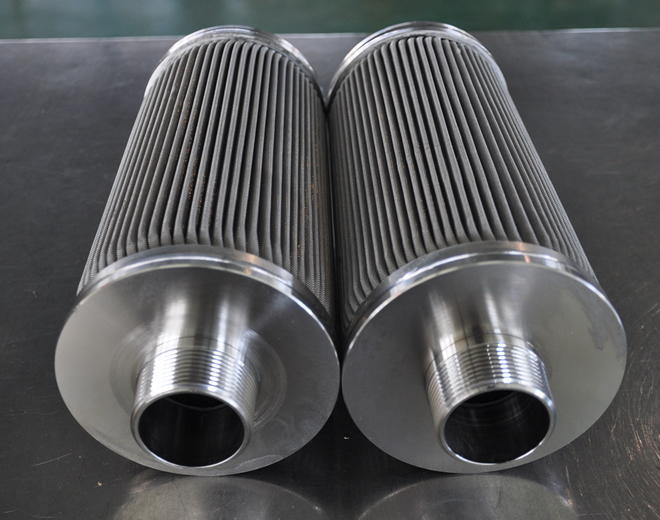

Advantages of Using Sintered Filter Cores in Petrochemical Filters:

1. Corrosion Resistance: Filters in the petrochemical industry often need to handle corrosive chemicals. Sintered filter cores are typically made of corrosion-resistant materials, allowing them to perform well in corrosive environments.

2. High-Temperature Resistance: Petrochemical processes often involve high-temperature operations. Sintered filter cores, made of high-temperature-resistant materials, can operate stably under high-temperature conditions, making them suitable for various high-temperature petrochemical processes.

3. Efficient Filtration: The structure of sintered filter cores is usually designed to be dense, effectively filtering tiny particles and ensuring the purity of liquids or gases in petrochemical processes.

4. High Mechanical Strength: Sintered filter cores undergo high-temperature sintering during manufacturing, resulting in high mechanical strength. They can withstand certain pressure and flow rates, ensuring reliable operation in petrochemical processes.

5. Longevity and Regenerability: Due to the materials and structure of sintered filter cores, they have a longer service life. Additionally, they can often be cleaned and regenerated, reducing the frequency of filter replacements and lowering maintenance costs.

6. Adaptation to High-Viscosity Liquids: Petrochemical processes sometimes involve high-viscosity liquids, and the design of sintered filter cores allows them to adapt to these special conditions.

Overall, using sintered filter cores in petrochemical filters provides stable, efficient, and corrosion-resistant filtration performance, suitable for complex petrochemical production environments. Choosing the appropriate sintered filter core model and material will help meet specific filtration requirements.