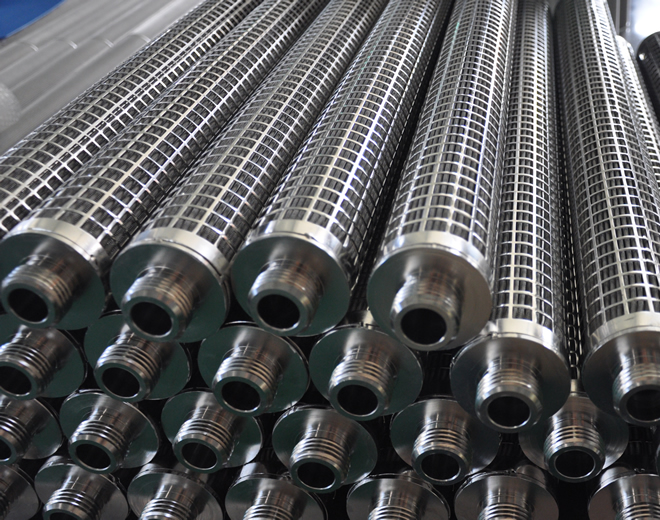

Advantages of Using Sintered Filter Cores in High-Temperature Gas Filters:

1. Excellent High-Temperature Performance: Sintered filter cores are typically made from high-temperature-resistant materials, allowing them to maintain stable performance in high-temperature environments. This makes high-temperature gas filters highly effective.

2. Good Chemical Stability: Sintered filter cores are often made of corrosion-resistant and chemically stable materials, resisting the corrosive effects of some gases and chemicals and enhancing the filter's lifespan.

3. High Mechanical Strength: The high-temperature sintering process imparts strong mechanical strength to the sintered filter cores. This strength ensures the integrity and stability of the filter structure under harsh conditions like high temperatures and pressures.

4. Ease of Cleaning and Regeneration: The stable structure of sintered filter cores makes them easy to clean. Some sintered filter cores even support multiple cleaning and regeneration cycles, reducing the need for frequent replacements and lowering operating costs.

5. Suitable for High Particle Loads: With a large filtering surface area, sintered filter cores can accommodate higher particle loads, making them suitable for applications involving high concentrations of particles.

It's important to note that while sintered filter cores have many advantages in high-temperature gas filtration, the selection of appropriate materials and models should align with specific application requirements to ensure efficient and stable filtration performance.