A metal filter element is a type of filtration medium constructed entirely from metal materials, typically stainless steel, aluminum, or other alloys. These filter elements are designed to effectively remove solid particles, contaminants, and impurities from liquids or gases while offering durability, reliability, and resistance to harsh operating conditions. Metal filter elements are widely used in various industries for their versatility, longevity, and superior filtration performance.

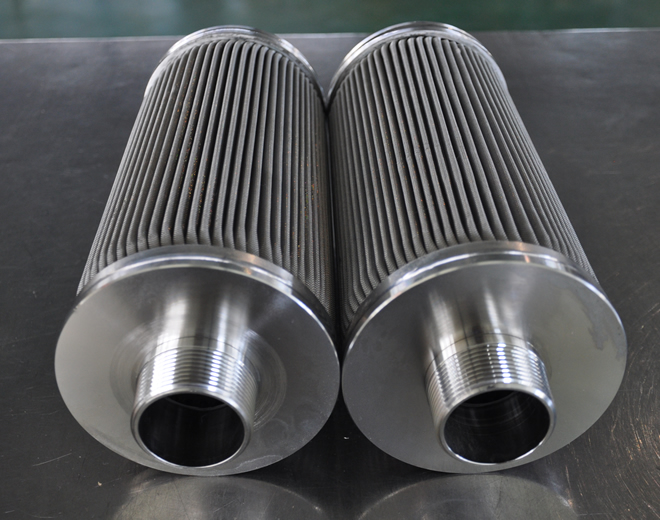

The construction of a metal filter element typically involves the use of metal mesh, perforated metal sheets, or sintered metal particles arranged in a specific configuration to achieve the desired filtration properties. Each type of metal filter element offers unique characteristics and advantages depending on the specific application requirements.

1. Metal Mesh Filter Elements: Metal mesh filter elements are constructed from woven wire mesh screens made from stainless steel or other metal alloys. These screens are layered and compressed to form a porous structure with controlled pore size and distribution. Metal mesh filter elements offer precise filtration with customizable pore sizes, making them suitable for applications requiring fine filtration and particle removal.

2. Perforated Metal Filter Elements: Perforated metal filter elements consist of metal sheets with precision-drilled holes arranged in a specific pattern to allow fluid flow while retaining solid particles and contaminants. These filter elements offer high mechanical strength and are suitable for applications where coarse filtration is required, such as wastewater treatment, hydraulic systems, and air filtration.

3. Sintered Metal Filter Elements: Sintered metal filter elements are manufactured by compressing and sintering metal powder particles to create a porous structure with controlled pore size and distribution. These filter elements offer high filtration efficiency and uniform particle capture, making them suitable for applications requiring fine filtration and removal of submicron particles. Sintered metal filter elements are commonly used in pharmaceutical manufacturing, food and beverage processing, and gas filtration applications.

Metal filter elements offer several advantages over other types of filtration media, including:

- Durability: Metal filter elements are highly durable and resistant to corrosion, chemicals, high temperatures, and mechanical stress, making them suitable for use in demanding industrial environments.

- Versatility: Metal filter elements can be customized to meet specific application requirements by adjusting pore size, thickness, and shape, allowing for flexibility in filtration system design.

- High Filtration Efficiency: Metal filter elements offer efficient particle capture and removal across a wide range of particle sizes, ensuring clean and pure process fluids.

- Longevity: Metal filter elements have a long service life and can withstand repeated cleaning and sterilization cycles, reducing maintenance costs and downtime in industrial operations.

Applications for metal filter elements span across various industries, including:

- Water Treatment: Filtration of potable water, wastewater, and industrial process water in municipal and industrial water treatment systems.

- Oil and Gas: Filtration of well fluids, hydraulic fluids, and natural gas in upstream and downstream oil and gas operations.

- Chemical Processing: Purification of process streams, removal of catalyst fines, and filtration of corrosive chemicals in chemical manufacturing plants.

- Pharmaceuticals: Filtration of pharmaceutical ingredients, sterile solutions, and process fluids in pharmaceutical manufacturing facilities.

- Food and Beverage: Clarification and purification of juices, syrups, oils, and beverages in food processing plants.

In summary, metal filter elements offer reliable and efficient filtration solutions for a wide range of industrial applications, providing durability, versatility, and high filtration performance in demanding operating environments.