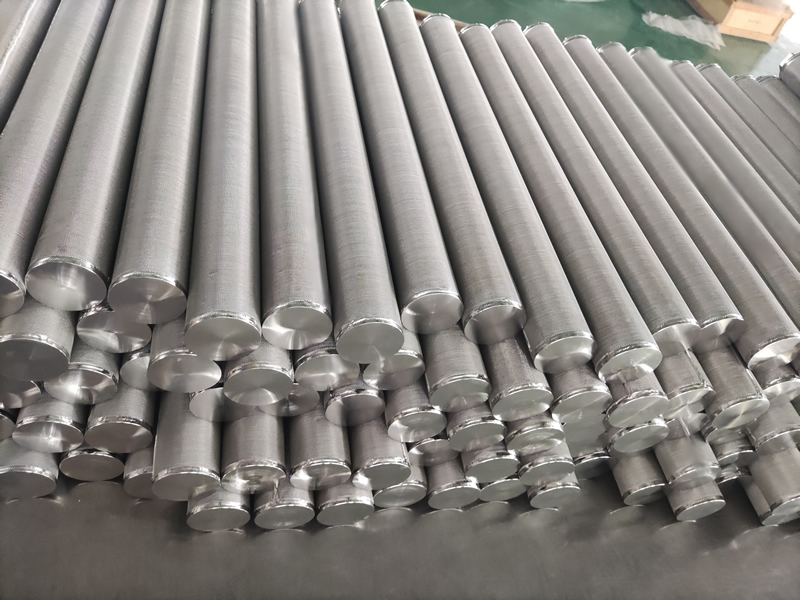

A sintered mesh filter element is a highly efficient filtration material that removes impurities from fluids through mechanisms such as physical interception, deep filtration, and diffusion. Its unique structure offers significant advantages in terms of filtration efficiency, durability, and regenerability, making it widely used in various industries.

1. Physical Interception

The primary working principle of a sintered mesh filter element is physical interception, where contaminants are trapped by the pores of its multi-layered metal mesh. When liquid or gas passes through the filter, larger particles are directly blocked on the surface or within the filter. The pore size of the filter is carefully designed to ensure that only particles small enough can pass through, effectively removing larger contaminants.

The multi-layer structure allows for gradient filtration, where the pore sizes gradually decrease across layers, ensuring comprehensive filtration from large particles to fine ones. Compared to single-layer filters, the multi-layer design of sintered mesh elements significantly improves filtration efficiency, dirt-holding capacity, and extends the filter's service life.

2. Deep Filtration

In addition to surface filtration, the sintered mesh filter also performs deep filtration. As smaller particles penetrate deeper into the filter, they are gradually captured within the internal layers of the mesh. Thanks to its three-dimensional mesh structure, contaminants are continuously trapped as the fluid flows through multiple layers, greatly enhancing the filter's ability to remove impurities.

Moreover, as the fluid passes through the sintered mesh filter, the flow rate decreases due to resistance, increasing the contact time between the fluid and the filter material. The longer the fluid remains in contact with the filter, the more effective the filtration process becomes.

3. Diffusion and Electrostatic Effects

For very fine particles, physical interception alone may not be sufficient. In such cases, the sintered mesh filter also relies on diffusion and electrostatic effects to remove microscopic impurities. Diffusion occurs as tiny particles move randomly (Brownian motion) and come into contact with the mesh, where they are captured. Additionally, certain filter materials may generate weak electrostatic charges that attract and capture charged particles, further improving the removal of small contaminants.

4. Backwashing and Regenerability

One of the key features of sintered mesh filters is their regenerability. Through backwashing or other cleaning methods, accumulated contaminants can be removed, restoring the filter to its original high filtration efficiency. This reusability greatly reduces operational costs and minimizes the need for frequent filter replacements.

Conclusion

Sintered mesh filters effectively remove impurities from fluids through mechanisms like physical interception, deep filtration, and diffusion. Their unique multi-layered structure not only enhances filtration precision but also provides strong durability and the ability to be regenerated, making them ideal for industries requiring efficient filtration. Whether for gas or liquid filtration, sintered mesh filters ensure fluid purity, protect equipment, and improve operational efficiency.