When purchasing stainless steel filters, it's essential to understand the following key parameters and information based on the specific application and filtration requirements to ensure selecting the right filter:

1. Filtration Accuracy

Definition: The smallest particle size that the filter can remove, usually measured in microns (μm).

Common Range: 1μm - 100μm, depending on the application.

Recommendation: Choose the appropriate filtration accuracy based on the particle size of the medium being filtered. For high-precision filtration (e.g., pharmaceuticals, electronics), select filters with lower micron values, while larger particles (e.g., pre-filtration) may require higher micron filters.

2. Filter Size

Definition: The physical dimensions of the filter, such as outer diameter, inner diameter, and length.

Importance: The filter must match the filtration equipment or housing, or it will not fit or function properly.

Recommendation: Verify the size requirements of the equipment, including length, diameter, and connection type.

3. Filter Medium

Definition: The type of fluid or gas that will flow through the filter.

Common Mediums: Water, oil, air, gases, chemicals, etc.

Recommendation: Select the appropriate filter material based on the type of medium. Stainless steel filters are ideal for corrosive, high-temperature, or high-pressure filtration needs.

4. Operating Temperature

Definition: The temperature range that the filter can withstand in the working environment.

Common Range: Stainless steel filters can typically handle high temperatures, with ranges from 300°C to 500°C.

Recommendation: Confirm the operating temperature of the filtration environment to ensure the filter can function properly within that range.

5. Operating Pressure

Definition: The pressure range that the filter can withstand during filtration, typically measured in bars (bar) or megapascals (MPa).

Common Range: 0.1MPa - 10MPa or higher.

Recommendation: Choose a filter that can handle the system's operating pressure to ensure it doesn’t deform or rupture under pressure.

6. Material

Definition: The specific type of stainless steel used in the filter, such as 304 stainless steel, 316 stainless steel, etc.

Material Selection: 304 stainless steel is suitable for general environments, while 316 stainless steel has better corrosion resistance for harsh environments like acids, alkalis, and salt fog.

Recommendation: Select the material based on the chemical properties of the medium. For highly corrosive environments, 316 stainless steel is recommended.

7. Flow Rate and Throughput

Definition: The volume of fluid the filter can handle, typically measured in liters per minute (L/min) or cubic meters per hour (m³/h).

Recommendation: Choose the filter's throughput based on the system's capacity to ensure it meets the actual filtration needs.

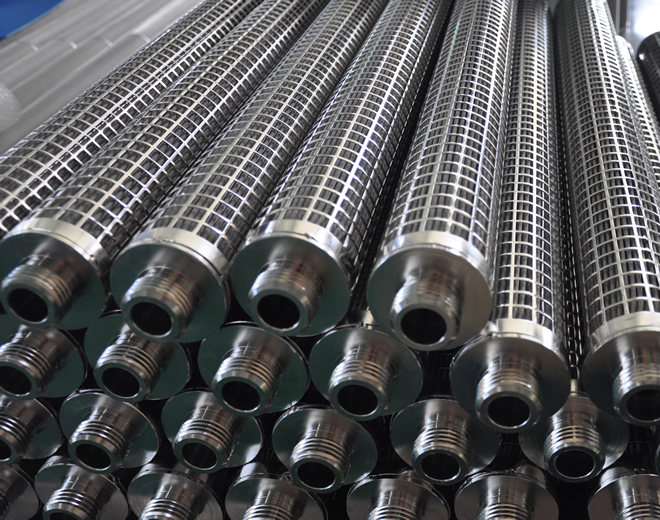

8. Filter Structure

Definition: The construction type of the filter, such as pleated, sintered mesh, or woven mesh.

Pleated Filters: Increase filtration area and improve throughput and service life.

Sintered Mesh Filters: Made from sintered metal mesh, offering strong pressure resistance and regeneration capability.

Recommendation: Select the appropriate structure based on the application. Pleated filters are ideal for high-flow applications.

9. Cleaning and Regeneration Capability

Definition: The ability of the filter to be cleaned and reused.

Importance: Stainless steel filters are usually washable and reusable, offering a long service life.

Recommendation: Confirm whether the filter supports cleaning and regeneration. Regular maintenance can significantly extend the filter's life and reduce replacement costs.

10. Connection Type

Definition: The filter's connection method, such as threaded, flanged, or quick-connect interfaces.

Recommendation: Choose the filter with a connection type that matches the equipment to ensure easy installation and maintenance.

11. Corrosion Resistance

Definition: The filter's ability to resist chemical corrosion in specific environments.

Recommendation: Select a filter with strong corrosion resistance based on the corrosiveness of the medium, and ensure proper material selection and surface treatment.

12. Certification Requirements

Definition: Some industries may require specific certifications or standards for filters (e.g., food-grade, pharmaceutical-grade certifications).

Recommendation: If the filter is used in industries like food processing or pharmaceuticals, choose products that comply with the relevant industry standards.

By understanding these key parameters, you can choose the most suitable stainless steel filter to ensure optimal performance in your application.